Creep and shrinkage using different code

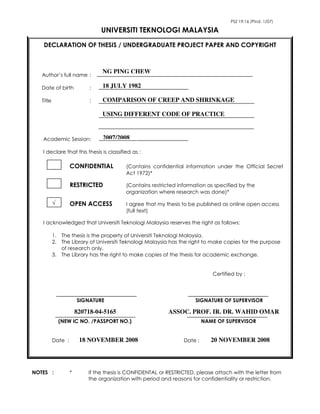

- 1. PSZ 19:16 (Pind. 1/07) UNIVERSITI TEKNOLOGI MALAYSIA DECLARATION OF THESIS / UNDERGRADUATE PROJECT PAPER AND COPYRIGHT NG PING CHEW Author’s full name : Date of birth : 18 JULY 1982 Title : COMPARISON OF CREEP AND SHRINKAGE USING DIFFERENT CODE OF PRACTICE Academic Session: 2007/2008 I declare that this thesis is classified as : CONFIDENTIAL (Contains confidential information under the Official Secret Act 1972)* RESTRICTED (Contains restricted information as specified by the organization where research was done)* √ OPEN ACCESS I agree that my thesis to be published as online open access (full text) I acknowledged that Universiti Teknologi Malaysia reserves the right as follows: 1. The thesis is the property of Universiti Teknologi Malaysia. 2. The Library of Universiti Teknologi Malaysia has the right to make copies for the purpose of research only. 3. The Library has the right to make copies of the thesis for academic exchange. Certified by : SIGNATURE SIGNATURE OF SUPERVISOR 820718-04-5165 ASSOC. PROF. IR. DR. WAHID OMAR (NEW IC NO. /PASSPORT NO.) NAME OF SUPERVISOR Date : 18 NOVEMBER 2008 Date : 20 NOVEMBER 2008 NOTES : * If the thesis is CONFIDENTAL or RESTRICTED, please attach with the letter from the organization with period and reasons for confidentiality or restriction.

- 2. DECLARATION “I/We* hereby declare that I/We* have read this project report and in my/our* opinion this project report is sufficient in terms of scope and quality for the award of the degree of Master of Engineering (Civil – Structure).” Signature : ………………………….……………….. ASSOC. PROF. IR. DR. WAHID Name of Supervisor : …………………………….…………….. Date 20 NOVEMBER 2008 : …………………………………..……… * Delete as necessary

- 3. COMPARISON OF CREEP AND SHRINKAGE USING DIFFERENT CODE OF PRACTICE NG PING CHEW A project report submitted in fulfillment of the requirements for the award of the degree of Master of Engineering (Civil – Structure) Faculty of Civil Engineering Universiti Teknologi Malaysia NOVEMBER 2008

- 4. ii I declare that this project report entitled “Comparison of Creep and Shrinkage Using Different Code of Practice” is the result of my own except as cited in the references. The project report has not been accepted for any degree and is not concurrently submitted in candidate of any degree. Signature : ………………………………………… NG PING CHEW Name : ………………………………………… Date : 18 NOVEMBER 2008 ………………………………………….

- 5. iii DEDICATION For my beloved family

- 6. iv ACKNOWLEDGEMENT The author is deeply indebted to his supervisor, Assoc. Prof. Ir. Dr. Wahid Omar whose help, stimulating suggestions and encouragement helped him in all the time of the study and preparation of this project. The author wishes to thank Mr. Edgar T. Almoite, for his helpful guidance. The author has furthermore to thank all the lecturers and staffs of Faculty of Civil Engineering UTM, for their advice and assistance throughout the study. Sincere appreciation also extends to all his friends for their help, support, interest and valuable hints. Last but not least, the author would like to express his deepest gratitude to his parents, Ng Soon and Ken Kim Moy, for unconditional support and encouragement to pursue his interest.

- 7. v ABSTRACT This project presents a study on the behavior of creep and shrinkage of concrete specimens. Prediction of creep and shrinkage strain was studied and compared based on British Standard 8110, Eurocode 2 and Australian Standard. The objective of this study is to understand the concrete behavior of creep and shrinkage and to produce a spread sheet of determining creep and shrinkage strain based on the three standards mentioned. The spread sheet will be used to ease future engineers in estimating creep and shrinkage strain of concrete in structural design work. Creep and shrinkage are two important time-dependent properties of concrete as it causes cracking and adversely affects the functionality, durability and appearance of structure. There are many parameters that affect the concrete creep and shrinkage strain such as concrete strength, type of cement, relative humidity, effective thickness, days of loading, etc. In this study, relative humidity of the environment was used as the controlled parameter in comparing the creep and shrinkage strain. Australian Standard was found to be limited in determining creep and shrinkage strain because it is based on climatic zones in Australia. However, prediction using Australian Standard is still being considered as each zone has its own range of relative humidity. Graph and formula method for Eurocode were considered in this study. Both of the methods gave acceptable results. In creep and shrinkage strain comparison, Eurocode present acceptable result with more conservative strain. This code of practice is preferable in determining concrete creep and shrinkage among the standards researched in this study.

- 8. vi ABSTRAK Projek ini membincangkan kajian kelakuan rayapan dan pengecutan atas spesimen konkrit. Anggapan rayapan dan pengecutan konkrit telah dikaji dan perbandingan telah dibuat berdasarkan British Standard 8110, Eurocode 2 dan Australian Standard. Tujuan kajian ini adalah untuk memahami kelakuan rayapan dan pengecutan konkrit serta menghasilkan spread sheet yang berfungsi untuk menentukan nilai rayapan dan pengecutan berpandukan ketiga-tiga kod rekabentuk tersebut. Spread sheet ini akan menyenangkan kerja jurutera dengan menentukan nilai rayapan dan pengecutan konkrit dalam rekabentuk struktur. Rayapan dan pengecutan merupakan ciri-ciri penting konkrit. Rayapan dan pengecutan akan menyebabkan keretakan konkrit, dimana menjejaskan struktur tersebut dari segi fungsi, ketahanan dan persembahan luarannya. Terdapat banyak parameter yang mempengaruhi rayapan dan pengecutan konkrit seperti kekuatan konkrit, jenis simen, kelembapan bandingan, kedalaman berkesan, masa pembebanan dan sebagainya. Dalam kajian ini, kelembapan bandingan alam persekitaran telah digunakan sebagai parameter pengawal dalam bandingan rayapan dan pengecutan. Didapati bahawa Australian Standard adalah terhad dalam menentukan nilai rayapan dan pengecutan disebabkan kod tersebut adalah berdasarkan zon cuaca Australia. Walau bagaimanapun, anggapan bagi nilai rayapan dan pengecutan konkrit berdasarkan Australian Standard masih dilaksanakan dalam kajian ini kerana setiap zon mempunyai kelembapan bandingannya masing- masing. Bagi Eurocode, kaedah graf dan formula telah digunakan dalam kajian ini. Kedua-dua kaedah tersebut telah menghasilkan keputusan yang memuaskan. Dalam perbandingan nilai rayapan dan pengecutan, Eurocode menghasilkan keputusan dengan konsevatif. Antara kod-kod yang digunakan, kod ini adalah lebih digemari dalam kajian ini untuk menentukan nilai rayapan dan pengecutan.

- 9. vii TABLE OF CONTENTS CHAPTER TITLE PAGE DECLARATION ii DEDICATION iii ACKNOWLEDGEMENT iv ABSTRACT v ABSTRAK vi TABLE OF CONTENTS vii LIST OF TABLES xii LIST OF FIGURES xiii LIST OF SYMBOLS xviii ABBREVIATION xx 1 INTRODUCTION 1 1.1 Background 1 1.2 Serviceability of Concrete Structures 5 1.3 Problem Statement 7 1.4 Objectives of Project 8 1.5 Scope of Work 9 1.6 Expected Outcome 10 2 LITERATURE REVIEW 11 2.1 Significance of Volume Changes and Creep 11 2.2 The Gel Structure as Related to Volume Changes 12

- 10. viii 2.3 Shrinkage of Concrete 13 2.3.1 Type of Shrinkage 14 2.3.1.1 Plastic Shrinkage 14 2.3.1.2 Autogeneous Shrinkage 15 2.3.1.3 Drying Shrinkage 16 2.3.1.4 Carbonation Shrinkage 19 2.3.2 Factors Affecting Shrinkage 22 2.3.2.1 Effect of Composition and Fineness of Cement 23 2.3.2.2 Effect of Type and Gradation of Aggregate 23 2.3.2.3 Effect of Cement and Water Contents 24 2.3.2.4 Effect of Admixtures 25 2.3.2.5 Temperature and Relative Humidity 27 2.3.2.6 Volume-to-Surface Ratio 27 2.3.2.7 Volume and Type of Aggregate 28 2.3.2.8 Elastic Modulus of Aggregate 29 2.3.3 Differential Shrinkage 29 2.3.4 Shrinkage-induced Cracking 32 2.3.5 Effect of Shrinkage 34 2.3.6 Methods of Controlling Shrinkage Cracking 34 2.3.6.1 Conventional Method 36 2.3.6.2 Innovative Method 39

- 11. ix 2.4 Creep of Concrete 42 2.4.1 Creep Behavior of Concrete 44 2.4.2 Components of Creep Strain 45 2.4.3 Factors Affecting Creep 47 2.4.3.1 Effect of Stress and Age When First Loaded 47 2.4.3.2 Effect of Water-Cement Ratio and Mix 47 2.4.3.3 Effect of Composition and Fineness of Cement 48 2.4.3.4 Effect of Character and Grading of Aggregate 49 2.4.3.5 Effect of Moisture Condition of Storage 50 2.4.3.6 Effect of Size of Mass 51 2.4.4 Effect of Creep 52 2.4.5 Test for Creep 53 2.4.5.1 Dead load 54 2.4.5.2 Spring-loaded 54 2.4.5.3 Hydraulic 54 2.4.5.4 Stabilized Hydraulic 55 3 PREDICTION METHODS 56 3.1 Introduction 56 3.2 Shrinkage 57 3.2.1 Drying Shrinkage Strain 57 3.2.2 British Standard 61 3.2.3 Australian Standard 64 3.2.3.1 Basic Shrinkage Strain 64 3.2.3.2 Design Shrinkage Strain 65

- 12. x 3.2.4 Eurocode 68 3.2.4.1 Eurocode (Annex B) 71 3.3 Creep 72 3.3.1 Creep Strain 72 3.3.2 British Standard 75 3.3.3 Australian Standard 77 3.3.3.1 Basic Creep Factor 77 3.3.3.2 Design Creep Factor 78 3.3.4 Eurocode 80 3.3.4.1 Eurocode (Annex B) 82 4 METHODOLOGY 86 4.1 Introduction 86 4.2 Information Gathering 86 4.3 Preparation of Spread Sheet 88 5 ANALYSIS OF RESULTS 89 5.1 Introduction 89 5.2 Shrinkage 89 5.2.1 Shrinkage Strain 90 5.2.2 British Standard 91 5.2.3 Australian Standard 92 5.2.4 European Standard 93 5.2.5 Comparison of Shrinkage Using Different Standards 95 5.3 Creep 97 5.3.1 Creep Strain 98 5.3.2 British Standard 99 5.3.3 Australian Standard 100 5.3.4 European Standard 101

- 13. xi 5.3.5 Comparison of Creep Using Different Standard 103 6 CONCLUSION AND RECOMMENDATIONS 105 6.1 Conclusions 105 6.2 Recommendations for Further Studies 107 REFERENCES 105 APPENDIX 109

- 14. xii LIST OF TABLES TABLE NO. TITLE PAGE 2.1 Shrinkage of neat cement in comparison with the 24 corresponding shrinkages of the same cement diluted with a single sieve size (No. 4 to 3/8 in.) of gravel and crushed limestone, respectively 2.2 Methods of controlling drying shrinkage 35 2.3 Aggregate type related to drying shrinkage 37 2.4 Effect of mineral character of aggregate upon creep 50 2.5 Effect of moisture condition of storage upon creep 51 3.1 Nominal unrestrained drying shrinkage values εcd,0 (%) 69 for concrete with cement CEM Class N 3.2 Values for kh 69 3.3 Basic creep factor 77

- 15. xiii LIST OF FIGURES FIGURE NO. TITLE PAGE 1.1 Relationship between concrete strain and time 5 2.1 Relationship between shrinkage and loss of water from 18 specimens of cement-pulverized silica pastes cured for 7 days at 21ºC and then dried 2.2 Loss of mass of concrete due to drying and carbonation 19 2.3 Drying shrinkage and carbonation shrinkage of mortar 20 at different relative humidity 2.4 Influence of the sequence of drying and carbonation of 21 mortar on shrinkage 2.5 The pattern of shrinkage as a function of cement content, 25 water content and water/cement ratio 2.6 Effect of W/C ratio and aggregate content on shrinkage 28

- 16. xiv 2.7 Relation between axial shrinkage and width of square 31 cross-section and length/width ratio of 4 2.8 Relation between ultimate shrinkage and 31 volume/surface ratio 2.9 Schematic pattern of crack development when tensile 33 stress due to restrained shrinkage is relieved by creep 2.10 Typical strain-time plot of concrete under sustained 43 load and after release of load 2.11 Recoverable and irrecoverable creep component 45 2.12 Creep components in drying specimen 46 2.13 Effect of water-cement ratio on creep 48 2.14 Creep in compression and tension for mass-cured 49 concretes 2.15 Effect of size of specimens upon creep 52 3.1 Coefficient KL 59 3.2 Coefficient Kc 59 3.3 Coefficient Ke 60

- 17. xv 3.4 Coefficient Kj 60 3.5 Drying shrinkage of normal-weight concrete 63 3.6 Shrinkage strain coefficient (k1) for various environments 66 3.7 Climatic Zones in Australia 67 3.8 Coefficient KL 73 3.9 Coefficient Km 74 3.10 Coefficient Ke 74 3.11 Effects of relative humidity, age of loading and section 76 thickness upon creep factor 3.12 Creep factor coefficient (k2) for various environments 79 3.13 Maturity coefficient (k3) 79 3.14 Method for determining the creep coefficient for concrete 82 under normal environmental conditions 5.1 Relationship between shrinkage and relative humidity 90 based on code of practice specified by Hong Kong government

- 18. xvi 5.2 Relationship between shrinkage and relative humidity 92 based on BS 8110 5.3 Relationship between shrinkage and relative humidity 93 based on AS 3600 5.4 Relationship between shrinkage and relative humidity 94 using table and formula method based on EC 2 5.5 Relationship between shrinkage and duration based on 95 EC 2 5.6 Comparison of shrinkage using different code of practice 97 5.7 Relationship between creep and relative humidity based 98 on code of practice specified by Hong Kong government 5.8 Relationship between creep and relative humidity 100 based on BS 8110 5.9 Relationship between creep and relative humidity 101 based on AS 3600 5.10 Relationship between creep and relative humidity 102 using graph and formula method based on EC 2 5.11 Comparison of creep using different standards 103

- 19. xvii 5.12 Relationship between creep and duration based on EC 2 104

- 20. xviii LIST OF SYMBOLS εcs / εss – shrinkage strain cs – modification factor to allow for properties of crushed granitic aggregate KL – coefficient relating to the environment (shrinkage) Kc – coefficient relating to the composition of the concrete (shrinkage) Ke – coefficient relating to the effective thickness of the section (shrinkage) Kj – coefficient defining the development of shrinkage relative to time Ks – reinforcement coefficient αe – modular ratio Es/Ec ρ – steel ratio As/Ac As – total area of longitudinal reinforcement Ac – gross cross-sectional concrete area Es – modulus of elasticity of the reinforcement Ec – short-term modulus of concrete εcs.b – basic shrinkage strain k1 – shrinkage strain coefficient εsd(t) – drying shrinkage strain in time εsd(t) – nominal unrestrained drying shrinkage εsa – autogeneous shrinkage strain h0 – effective thickness u – perimeter of the member in contact with the atmosphere

- 21. xix kh – coefficient depending on h0 fcm – the mean compressive strength (MPa) αds1 – coefficient which depends on the type of cement αds2 – coefficient which depends on the type of cement E28 – static modulus of elasticity at 28 days Et – modulus of elasticity at an age t Eu – modulus of elasticity at age of unloading Øc – creep coefficient depending on KL, Km, Kc, Ke, Kj Km – coefficient relating to the hardening (maturity) of the concrete Øcc.b – basic creep factor of concrete k2 – creep factor coefficient k3 – maturity coefficient φ – creep coefficient kσ – stress-strength ratio σc/fcm φ0 – notional creep coefficient φRH – factor to allow for the effect of relative humidity on the notional creep coefficient βc(t,t0) – coefficient to describe the development of creep with time after loading βH – coefficient depending on the relative humidity and the notional member size t – age of concrete in days at the moment considered t0 – age of concrete at loadings in days fcu,28 – 28 day cube strength in N/mm2 fcu,t – cube strength at an age t σc – compressive stress in concrete

- 22. xx ABBREVIATION BS 8110 - British Standard 8110 AS 3600 - Australian Standard 3600 EC 2 - European Standard Eurocode 2 RH - Relative Humidity

- 23. CHAPTER 1 INTRODUCTION 1.1 Background Concrete is a composite building material made from the combination of aggregate and cement binder. The most common form of concrete consists of Portland cement, mineral aggregates (generally gravel and sand) and water. Contrary to common belief, concrete does not solidify from drying after mixing and placement. Instead, the cement hydrates, gluing the other components together and eventually creating a stone- like material. When used in the generic sense, this is the material referred to by the term concrete. The quality of concrete can be assessed from several characteristics, namely its strength, durability, creep and shrinkage. These are the most important and common criteria used to grade a concrete into its quality level. A concrete of good quality should be able to work up to the structural ability for which it is designed for, and also to last for at least the design lifetime for which it is designed for.

- 24. 2 The behavior of hardened concrete can be characterized in terms of its short-term (essentially instantaneous) and long-term properties. Short-term properties include strength in compression, tension, bond, and modulus of elasticity [17]. The long-term properties include creep, shrinkage, behavior under fatigue, and durability characteristics such as porosity, permeability, freeze-thaw resistance, and abrasion resistance [17]. Concrete is one of the most durable construction materials. However, cracking adversely affects its durability, functionality, and appearance. A major cause of cracking is related to shrinkage-induced strains, creating stresses when concrete is restrained [4]. The shrinkage of concrete is often attributed to drying of the concrete over a long period of time, and recent observations have also focused on early age shrinkage and creep problems. Cracked concrete typically needs to be repaired to prevent further deterioration due to freezing and thawing, and corrosion of steel reinforcement resulting from infiltration of water with or without chloride ions from de- icing salts. The cracking leads to additional costs for repair to prevent premature deterioration of the concrete and the corrosion of reinforcement steel. The early age of concrete is known to have a significant control on the overall performance of concrete structures. During this stage, concrete may be subjected to severe internal actions due to thermal and hydric gradients within concrete itself and at the same time it may be affected by the external conditions of environment and loading [18]. All these actions may lead to different deformations within the concrete that is just building its resistance and stiffness. Creep and shrinkage of concrete are known to have significant effect at early age of concrete. Thus, discussing the performance of this young age concrete with special attention to the shrinkage and creep and time dependent deformations is of interest by many researchers.

- 25. 3 In predicting the strength and serviceability of reinforced and pre-stressed concrete structures, appropriate descriptions of the mechanical properties of the materials are required including the prediction of the long term behavior of the concrete. The prediction of short-term shrinkage and creep is also important to assess the risk of concrete cracking and stripping and unshoring times [17]. The mechanical properties of concrete are significantly affected by the temperature and availability of water during curing, the environmental humidity and temperature after curing, and the composition of the concrete, including the mechanical properties of the aggregates. When concrete is subjected to sustained compressive stress, deformations continue to increase with time due to creep and shrinkage. Creep strain is produced by sustained stress. Shrinkage strains are independent of stress and are caused by chemical reactions in the hydrating cement paste and by the loss of water during the drying process. The creep and shrinkage deformations in a concrete structure are frequently larger, and in some cases much larger than the initial deformations produced when the external loads are first applied [7]. They thus have a significant effect on service-load behavior. The resistance to deformation that makes concrete a useful material means also that volume changes of the concrete itself can have important implications in use. Any potential growth or shrinkage may lead to complications, externally because of structural interaction with other components or internally when the concrete is reinforced. There may even be distress if either the cement paste or the aggregate changes dimension, with tensile stresses set up in one component and compressive stresses in the other. Cracks may be produced when the relatively low tensile strength of the concrete or its constituent materials is exceeded.

- 26. 4 Cracking not only impairs the ability of a structure to carry its design load but also affect its durability and damage its appearance. In addition, shrinkage and creep may increase deflections in one member of a structure, adversely affecting the stability of the whole. Volume change of concrete is not usually associated with changes that occur before the hardened state is attained. Quality and durability, on the other hand, are dependent on what occurs from the time the concrete mix has been placed in the mold. Control of cracking may also be done by providing appropriate reinforcement. The reinforcement, however, does not reduce shrinkage but helps to keep cracks from widening. The use of expansive cements, coal-combustion products containing calcium sulfite or sulfate, and fibers is one way of counteracting shrinkage. Usually, expansive cements and clean-coal ash produce expansion by formation of ettringite. When the expansion is restrained by reinforcement, a compressive pre-stress is induced in concrete, compensating shrinkage. Figure 1.1 illustrates the relationship between various measured and derived strain values. The figure shows that the concrete undergoes autogenous shrinkage before drying. Once drying commences at time t0, drying shrinkage occurs. Upon loading, both drying and basic creep occurs in the drying specimen.

- 27. 5 Figure 1.1: Relationship between concrete strain and time [8] 1.2 Serviceability of Concrete Structures For a concrete structure to be serviceable, cracking must be controlled and deflections must not be excessive. The design for serviceability is possibility the most difficult and least well understood aspect of the design of concrete structures. Service load behavior depends primarily on the properties of the concrete and these are often not known reliably at the design stage. Concrete behaves in a non-linear and inelastic manner at service loads and the non-linear behavior that complicates serviceability calculations is due to cracking, tension stiffening, creep, and shrinkage. The control of cracking in a reinforced or pre-stressed concrete structure is usually achieved by limiting the stress increment in the bonded reinforcement to some

- 28. 6 appropriately low value and ensuring the bonded reinforcement is suitably distributed. For deflection control, engineer should select maximum deflection limits that are appropriate to the structure and its intended use. The calculated deflection must not exceed these limits. The quest for serviceable concrete structures must involve the development of more reliable design procedures. It must also involve designers giving more attention to the specification of an appropriate concrete mix, particularly with regard to the creep and shrinkage characteristics of the mix, and sound engineering input is required in the construction procedures. When designing for serviceability, engineer must ensure that the structure can perform its intended function under the day to day service loads. Deflection must not be excessive, cracks must be adequately controlled and no portion of the structure should suffer excessive vibration. Shrinkage cause time-dependent cracking, thereby reducing the stiffness of a concrete structure, and is therefore a detrimental factor in all aspects of the design for serviceability. Excessive wide cracks can be unsightly and spoilt the appearance of an exposed concrete surface. They allow the ingress of moisture accelerating corrosion of the reinforcement and durability failure. In exceptional cases, they reduce the contribution of the concrete to the shear strength of a member. Excessively wide cracks in floor systems and walls may often be avoided by the inclusion of strategically placed contraction joints, thereby removing some of the restraint to shrinkage and reducing the internal tension. When cracking occurs, in order to ensure that crack widths remain acceptably small, adequate quantities of well distributed and well-anchored reinforcement must be included at every location where significant tension will exist.

- 29. 7 Deflection problems that may affect the serviceability of concrete structures can be classified into three main types: a. Where excessive deflection causes either aesthetic or functional problems. b. Where excessive deflection results in damage to either structural or non- structural element attached to the member. c. Where dynamics effects due to insufficient stiffness cause discomfort to occupants. 1.3 Problem Statement Creep and shrinkage are very important time-dependent properties of concrete. They are in direct relation to the performance of concrete. The prediction of time- dependent behaviour is the most uncertain part of the design of concrete structures. Moreover, the prediction of the time-dependent behaviour is important not only for the structural maintenance after its completion, but also for the stress and deformation control during the erection stages of the structure. Most of the engineers today do not consider the concrete behaviour of creep and shrinkage in their design work because of lacking experience and understanding on the phenomenon and the effect on concrete specimen. Most of them consider creep and shrinkage cracks as non-structural cracks which is not important and will not cause any serious effect on concrete specimen. This assumption and consideration is not true because cracking deteriorate concrete’s durability and integrity. A number of analytical

- 30. 8 techniques are available for the prediction of creep and shrinkage on concrete members. However, each has its own simplifying assumptions, advantages and disadvantages. Some of those codes are more suited to particular conditions than others such as parameters used in BS are based on the conditions in Europe which may not be accurately applicable in Malaysia. Therefore, the study is mainly concentrates on the understanding of concrete behaviour due to creep and shrinkage and to study the prediction of creep and shrinkage strain using different code of practice. 1.4 Objectives of Project Based on the scope of work, the objectives of the project are defined below: (i) Study the properties and deformation of concrete due to creep and shrinkage. (ii) Evaluate and identify the parameters and method used in determining the coefficient of creep and shrinkage for British Standard, Eurocode and Australia Standard. (iii) Develop spreadsheets that calculating the creep and shrinkage of concrete for British Standard, Eurocode and Australia Standard. (iv) Compare the creep and shrinkage strain using BS8110, EC2 and AS3600 under controlled parameters.

- 31. 9 1.5 Scope of Work Time-dependent concrete deformation is nowadays one of the concerns in engineering field as it affects the serviceability and aesthetic of the concrete structures. The main factors that cause concrete deforms due to environment and applied stress are shrinkage and creep. Therefore, the research on this topic has been proposed in the Final Year Project of Master Studies (Civil-Structural) in Universiti Technologi Malaysia. In Masters Pre Project, the scope of work was mainly focused on the literature review of related studies. Substantial information on concrete properties such as modulus of elasticity, creep and shrinkage will be gathered through latest journals and publications in libraries and also articles from internet. The history of concrete, effect of admixtures on concrete properties and factors affecting deterioration on concrete and the effects are studied in this study. In Masters Project, detail studies on the concrete deformation due to time- dependent factors (creep and shrinkage) will be made. The formulas, and method used in predicting concrete deformation due to creep and shrinkage will be identified using British Standard, EURO Code and Australia Standard. Spread sheet to determine concrete creep and shrinkage will be produced by inputting the controlling parameters such as strength of concrete (fcu), relative humidity, type of cement, effective thickness, provided steel reinforcement, etc.

- 32. 10 1.6 Expected Outcome There are some outcomes to be expected through this master research studies such as: (i) To understand the concrete properties due to creep and shrinkage. (ii) To be familiar with the codes in creep and shrinkage of concrete specification. (iii) To understand the parameter and method used in calculating concrete creep and shrinkage for British Standard, Eurocode & Australia Standard.

- 33. CHAPTER 2 LITERATURE REVIEW 2.1 Significance of Volume Changes and Creep If concrete is free to deform, any volume changes would be of little consequence, but usually it is restrained by foundations, steel reinforcement, or by adjacent concrete subject to different conditions. As the potential movement is thus restrained, stresses will be developed which may rupture the concrete. This is particularly true when tension is developed; thus, contractions causing tensile stress are more important than expansions which cause compressive stress. Difference in moisture contents of the exposed and unexposed faces of thin concrete slabs, such as highways and canal linings, may cause curling and eventual cracking. Cracking not only may impair the ability of any structure to carry its designed loads, but it also may affect its durability and damage its appearance. The durability is affected by the entry of water through cracks, which corrodes the steel, leaches out soluble components, and deteriorates the concrete when subjected to freezing and thawing.

- 34. 12 Creep, in general, tends to relieve the stress in concrete, especially when reinforced. Thus, when a sustained load is applied to a reinforced concrete column, creep of the concrete causes a gradual reduction in the load on the concrete and a corresponding increase in the load on the steel. In various structural elements such as continuous beams and slabs, creep relieves some of the stress in the most highly stressed portions and increases the stress in adjacent portions of the concrete, so that finally the stresses are more uniform throughout the member. This relieving of the higher stresses serves to reduce the tendency toward cracking. However, creep may cause objectionable sagging of thin, long-span floor slabs or other structural elements. 2.2 The Gel Structure as Related to Volume Changes Cement, after hydration, consists of crystalline material plus a calcium silicate gel resulting from the combination of cement and water. The amount of the gel increases with the age of hydration and is greater for higher water-cement ratios and for finer cements. The amount of gel also depends upon the chemical composition of the cement, as fully hydrated dicalcium silicate is believed to be mostly gel, while hydrated tricalcium silicate is more than half gel. For the water-cement ratios used in average concrete, the gel has a larger volume than the crystalline portions. The crystalline materials in cement are believed to be unaffected by ordinary drying, but the gel is finely porous and undergoes large volume changes upon wetting and drying. The quantity and characteristics of the calcium silicate gel, therefore, largely determine the potential shrinkage upon drying of hydrated cement.

- 35. 13 Water is held in the pores of the gel by such large attractive forces that when it is removed from the pores by evaporation, the forces which formerly attracted the water become effective in compressing and reducing the volume of the gel. All concretes, then, are subject to moisture volume changes in some degree, and the problem involved is so to control conditions that the volume changes have small or practically harmless effects upon the integrity of the structure. 2.3 Shrinkage of Concrete Concrete deformation due to movement of water from or to the ambient medium when no external stress is acting is termed shrinkage. It is independent of stress and is caused by chemical reactions in the hydrating cement paste and by the loss of water during the drying process. Technically, shrinkage will continue for the life of the concrete, but most shrinkage will occur within the first 90 days after placement [33]. Shrinkage cracking is a major cause of concern for concrete structures. In addition to weakening the structure, these shrinkage cracks have the potential to allow infiltration of moisture and chloride ions that accelerate the corrosion of steel reinforcement and reduce the durability of concrete.

- 36. 14 2.3.1 Type of Shrinkage The four main types of shrinkage associated with concrete are plastic shrinkage, autogenous shrinkage, drying shrinkage, and carbonation shrinkage. 2.3.1.1 Plastic Shrinkage Plastic shrinkage is associated with moisture loss from freshly poured concrete into the surrounding environment. Plastic shrinkage occurs only in fresh concrete. The most common mechanism is the evaporation of water from the surface of the plastic concrete. However, the loss of water through the sub-base or formwork can exacerbate the effects of surface evaporation [33]. In the fresh concrete, the particles are completely surrounded by water. If water is removed from the system, menisci are formed between particles. These menisci generate negative capillary pressure, which pulls the cement particles together. By pulling on the particles, the capillary stresses tend to reduce the volume of the cement paste. Capillary pressures continue to rise as water is lost at the surface of the concrete. When the pressures reach a critical value, the water that remains in the concrete rearranges to form discrete zones with voids between them. Plastic shrinkage cracking occurs at this point.

- 37. 15 2.3.1.2 Autogenous Shrinkage Autogenous shrinkage is the volume change of the cement paste due to self- desiccation and chemical shrinkage after initial setting has occurred. Autogenous shrinkage is a microscopic volume change occurring after the initial setting in situations where the supply of water from outside of concrete is not enough. As the hydration of cementitious materials progresses, very fine pores are produced within the hardened cement paste due to the formation of calcium silicate hydrate (CSH) gel. As the hydration further progresses, capillary pore water and gel water is consumed and menisci are produced in these pores due to a lack of water supply from outside. As a result of negative pressure in the pores, hardened paste shows shrinkage [18]. Autogenous shrinkage is the early shrinkage of concrete caused by the loss of water from capillary pores due to the hydration of cementitious materials, without the loss of water into the surrounding environment. This phenomenon is known as self- desiccation of concrete. Self-desiccation occurs in all concrete irrespectively of the water-cement ratio. However, its effects are very different in normal concrete and high- performance concrete. In high-performance concrete, significantly more cementitious materials and less mixing water are used compared with normal concrete. In normal concrete, there is substantially more water than required for hydration of cementitious materials particles. This excess amount of water is contained in well-connected capillaries. Menisci created by the process of self-desiccation occur in large capillaries. But, stresses generated in large capillaries are very low, resulting in lower autogenous shrinkage. On the other hand, in case of high-performance concrete, pore network is essentially composed of fine capillaries due to low water-cement ratio and high amounts of cementitious hydration products. When self-desiccation starts to take place, very high tensile stresses are generated in these fine pores, resulting in higher autogenous shrinkage.

- 38. 16 Although autogenous shrinkage is three-dimensional, it is usually expressed as a linear stain so that it can be considered alongside the drying shrinkage. Typical values of autogenous shrinkage are about 40 x 10-6 at the age of one month and 100 x 10-6 after five years. Autogenous shrinkage tends to increase at higher temperatures, with higher cement content, and possibly with finer cements, and with cements which have a high C3A and C4AF content. At a constant content of blended cement, a higher content of fly ash leads to lower autogenous shrinkage. As self-desiccation is greater at lower water/cement ratios, autogenous shrinkage could be expected to increase but this may not occur because of the more rigid structure of the hydrated cement paste at lower water/cement ratios. Nevertheless, at very low water/cement ratios, autogenous shrinkage is very high: a value of 700 x 10-6 was reported for concrete with a water/cement ratio of 0.17 [1]. 2.3.1.3 Drying Shrinkage Drying shrinkage is different from autogenous shrinkage with regard to the mechanism of a decrease in humidity. Drying shrinkage is caused by the diffusion of water from concrete into the outer surrounding environment. Drying shrinkage refers to the reduction in concrete volume resulting from the loss of capillary water by evaporation. This shrinkage causes an increase in tensile stress of restrained concrete, which leads the concrete to cracking, internal warping, and external deflection, even if the concrete is not subjected to any kind of external loading.

- 39. 17 According Mehta and Monteiro the change in volume of drying concrete is not equal to the volume of water removed [2]. The reason is that the loss of water from large capillaries may be considered as free water, and its removal does not cause volume change. Loss of water held by capillary tension in small capillaries may cause shrinkage of concrete. It is also possible that shrinkage is related to the removal of interlayer water, which is also known as zeolite water. It has been suggested that a monomolecular water layer between the layers of CSH is strongly held by hydrogen bonding. This water is associated with CSH structure and the interlayer water is lost only on strong drying. The drying shrinkage of hydrated cement paste begins at the surface of the concrete. Depending on the relative humidity of the ambient air and the size of capillaries in the cement paste structure, drying shrinkage progresses more or less rapidly through concrete. The drying in ordinary concrete is, therefore, rapid because the capillary network is well connected and contains large capillaries. In the case of high-performance concrete, drying shrinkage is slow because the capillaries are very fine and soon get disconnected by hydration products. The influence of the gel particle size on drying is shown by the low shrinkage of the much more coarse-grained natural building stones and by the high shrinkage of fine grained shale [3]. Also, high-pressure steam-cured cement paste, which is microcrystalline and has a low specific surface, shrinks 5 to 10 times [4], and sometimes even 17 times [5], less than a similar paste cured normally. It is possible also that shrinkage, or a part of it, is related to the removal of intracrystalline water. Calcium silicate hydrate has been shown to undergo a change in lattice spacing from 1.4 to 0.9 nm on drying [6]; hydrated C4A and calcium sulfoaluminate show similar behavior [7]. It is thus not certain whether the moisture

- 40. 18 movement associated with shrinkage is inter- or intracrystalline. But, because paste made with both Portland and high-alumina cements, and also with pure ground calcium monoaluminate, exhibit essentially similar shrinkage, the fundamental cause of shrinkage must be sought in the physical structure of the gel rather than in its chemical and mineralogical character [6]. The relation between the mass of water lost and shrinkage is shown in Figure 2.1. For neat cement pastes, the two quantities are proportional to one another as no capillary water is present and only adsorbed water is removed. However, mixes to which pulverized silica has been added and which, for workability reasons, require a higher water/cement ratio, contain capillary pores even when completely hydrated. Emptying of the capillaries causes a loss of water without shrinkage but, once the capillary water has been lost, the removal of adsorbed water takes place and causes shrinkage in the same manner as in a neat cement paste. Figure 2.1: Relationship between shrinkage and loss of water from specimens of cement-pulverized silica pastes cured for 7 days at 21ºC and then dried [3]

- 41. 19 2.3.1.4 Carbonation Shrinkage In addition to shrinkage upon drying, concrete undergoes shrinkage due to carbonation, and some of the experimental data on drying shrinkage include the effects of carbonation. Drying shrinkage and carbonation shrinkage are, however quite distinct in nature. Carbonation shrinkage is caused by the chemical reactions of various cement hydration products with carbon dioxide present in the air. This type of shrinkage is usually limited to the surface of the concrete. Because of carbon dioxide is fixed by the hydrated cement paste, the mass of the latter increases. Consequently, the mass of concrete also increases. When the concrete dries and carbonates simultaneously, the increase in mass on carbonation may at some stage give the misleading impression that the drying process has reached stage of constant mass, i.e. equilibrium (see Figure 2.2). Figure 2.2: Loss of mass of concrete due to drying and carbonation [8]

- 42. 20 Carbonation shrinkage is probably caused by the dissolving of crystals of Ca(OH)2 while under a compressive stress (imposed by the drying shrinkage) and depositing of CaCO3 in spaces free from stress; the compressibility of the hydrated cement paste is thus temporarily increased. If carbonation proceeds to the stage of dehydration of C-S-H, this also produces carbonation shrinkage. Figure 2.3 shows the drying shrinkage of mortar specimens dried in CO2 – free air at different relative humidity, and also the shrinkage after subsequent carbonation. Carbonation increases the shrinkage at intermediate humidity, but not at 100 per cent or 25 per cent. In the latter case, there is insufficient water in the pores within the cement paste for CO2 to form carbonic acid. On the other hand, when the pores are full of water, the diffusion of CO2 into the paste is very slow; it is also possible that the diffusion of calcium ions from the paste leads to precipitation of CaCO3 with a consequent clogging of surface pores. Figure 2.3: Drying shrinkage and carbonation shrinkage of mortar at different relative humidity [9]

- 43. 21 The sequence of drying and carbonation greatly affects the total magnitude of shrinkage. Simultaneous drying and carbonation produces lower total shrinkage than when drying is followed by carbonation (Figure 2.4) because, in the former case, a large part of the carbonation occurs at relative humidity above 50 per cent; under such conditions carbonation shrinkage is reduced. Carbonation shrinkage of high-pressure steam-cured concrete is very small. Figure 2.4: Influence of the sequence of drying and carbonation of mortar on shrinkage [9] When concrete is subjected to alternating wetting and drying in air containing CO2, shrinkage due to carbonation becomes progressively more apparent. The total shrinkage at any stage is greater than if drying took place in CO2 – free air. However, carbonation of concrete prior to exposure to alternating wetting and drying reduces the moisture movement.

- 44. 22 2.3.2 Factors Affecting Shrinkage Generally, plastic shrinkage results from surface evaporation due to environmental conditions, such as humidity, wind speed or ambient temperature. ACI 305R, Hot Weather Concreting [10], provides guidance for placement of concrete to minimize plastic shrinkage cracking. Several factors which may be expected to influence the magnitude of volume changes in mortars and concretes caused by variations in moisture conditions, which take place with time and the simultaneous hardening of the cement paste are [34]: (i) Composition and fineness of the cement (ii) Cement and water contents (iii) Type and gradation of aggregate (iv) Admixtures (v) Age at first observation (vi) Duration of tests (vii) Moisture and temperature conditions (viii) Size and shape of specimen (ix) Absorptiveness of forms (x) Amount and distribution of reinforcement

- 45. 23 2.3.2.1 Effect of Composition and Fineness of Cement Cement properties and cement content in concrete influence concrete shrinkage. As the fineness of cement increases, so does the hydration rate of cement, leading to an increase to an increase in autogenous shrinkage of concrete. Small autogenous expansion as opposed to shrinkage may be produced through the use of coarser cements. Therefore, early age cracking could be possibly being avoided. Although coarser particles of cement are relatively beneficial in minimizing early age cracking, they may be detrimental to long-term strength. Mehta and Monteiro [2] state that the variation in fineness and composition of Portland cement affect the rate of hydration, but not the volume and characteristics of hydration products. Therefore, normal changes in fineness and composition of cement have negligible effect on drying shrinkage of concrete. Higher cement content with lower W/C in concrete results in higher autogenous shrinkage due to self-desiccation and chemical shrinkage, but may reduce drying shrinkage due to dense microstructure and poor pore connectivity. 2.3.2.2 Effect of Type and Gradation of Aggregate The drying shrinkage of concrete is not related to a fraction of neat cement as the aggregate particles not only dilute the paste but they reinforce it against contraction. Tests have shown that if the aggregate were readily compressible, as when using porous but nonabsorbent rubber particles, the concrete would shrink as much as neat cement. The ability of normal aggregates to restrain the shrinkage of a cement paste depends upon (1) extensibility of the paste, (2) degree of cracking of the paste, (3) compressibility of the aggregate, and (4) volume change of aggregate due to drying. In table A is shown the shrinkage of neat cement in comparison with the corresponding

- 46. 24 shrinkages of the same cement diluted with a single sieve size (No. 4 to 3/8 in.) of gravel and crushed limestone, respectively. The reduction in shrinkage due to the aggregate is greater than would be expected considering its relative volume. It is possible that internal cracking of the paste due to the restraint of the aggregate is a factor. Table 2.1: Shrinkage of neat cement in comparison with the corresponding shrinkages of the same cement diluted with a single sieve size (No. 4 to 3/8 in.) of gravel and crushed limestone, respectively [35] 2.3.2.3 Effect of Cement and Water Contents The water content is probably the largest single factor influencing the shrinkage of cement paste and concrete. Tests have shown that for cements having normal shrinkage characteristics, the shrinkage of the cement paste varies directly with the water-cement ratio [33]. Figure 2.5 shows the pattern of shrinkage as a function of cement content, water content, and water/cement ratio where the concrete is moist-cured for 28 days, thereafter dried for 450 days [11]. At a constant water/cement ratio, shrinkage increases with an

- 47. 25 increase in the cement content because this results in a larger volume of hydrated cement paste which is liable to shrinkage. However, at a given workability, which approximately means a constant water content, shrinkage is unaffected by an increase in the cement content, or may even decrease, because the water/cement ratios is reduced and the concrete is therefore, better able to resist shrinkage. Figure 2.5: The pattern of shrinkage as a function of cement content, water content and water/cement ratio [11] 2.3.2.4 Effect of Admixtures Admixtures can adversely affect the shrinkage potential of concrete. For instance, water reducers can be used to reduce the paste volume and thereby enhance the creep capacity without the loss of workability. Set retarders can be used to delay set and to decrease the amount of heat of hydration. A lower heat of hydration will decrease the thermal shock on the hydrating concrete [33]. However, overly long retardations will increase the potential for plastic shrinkage cracking. Proper curing is necessary with the

- 48. 26 use of a set retarder. Conversely, set accelerators increase the heat of hydration and early-age shrinkage. This combination will increase transverse shrinkage and the resulting cracking. Shrinkage-reducing admixtures (SRAs) are also available. These admixtures reduce the drying shrinkage by reducing the surface tension of the water in the capillary pores. If the surface tension of the water is reduced, there is less tension transferred to the capillary walls, and consequently less shrinkage. Laboratory evaluations have shown a slight decrease in compressive strength when an SRA is used. Taking advantage of the water-reducing properties of SRAs can offset the decrease in strength. Shrinkage of concrete made with high-alumina cement is of the same magnitude as when Portland cement is used, but it takes place much more rapidly [12]. Including either fly ash or ground granulated blastfurnace slag in the mix increases shrinkage. Specifically, at a constant water/cement ratio, a higher proportion of fly ash or slag in the blended cement leads to higher shrinkage by some 20 percent with the former material and by up to 60 percent at very high contents of slag [13]. Silica fume increases the long-term shrinkage [14]. Water-reducing admixtures per se probably cause a small increase in shrinkage. Their main effect is indirect in that the use of an admixture may result in a change in the water content or in the cement content of the mix, or in both, and it is the combined action of those changes that influences shrinkage. Superplasticizers have been found to increase shrinkage by some 10 to 20 percent. However, the changes in the observed shrinkage are too small to be accepted as reliable and generally valid.

- 49. 27 Entrainment of air has been found to have no effect on shrinkage [15]. Added calcium chloride increases shrinkage, generally between 10 and 50 percent [16], probably because a finer gel is produced and possibly because of greater carbonation of the more matures specimens with calcium chloride. 2.3.2.5 Temperature and Relative Humidity A high temperature and low relative humidity of the ambient environment accelerate the diffusion of the adsorbed water and capillary water into the atmosphere, and consequently, increases the drying shrinkage of concrete. An increase in the atmospheric humidity slows down the rate of moisture flow from the interior to the outer surface of concrete. Mehta and Monteiro [2] states that at 0% relative humidity, it is assumed that the drying shrinkage of concrete is zero. 2.3.2.6 Volume-to-Surface Ratio The size and shape of a concrete element have a considerable effect on the rate and total amount of shrinkage. The size and shape are often considered together as the volume-to-surface area ratio. A high volume-to-surface ratio usually results in lower shrinkage magnitudes.

- 50. 28 2.3.2.7 Volume and Type of Aggregate Drying shrinkage of concrete is a fraction of that of neat cement because the aggregate particles not only dilute the paste but reinforce it against contraction. The size and grading of aggregate do not, by themselves, influence the magnitude of shrinkage, but an aggregate incorporating larger sizes permits the use of a mix with less cement and hence a lower shrinkage. The shrinkage of aggregates themselves may be of considerable importance in determining the shrinkage of concrete. Some fine-grained sandstones, slate, basalt, trap rock and aggregates containing clay show large shrinkage while concretes low in shrinkage often contain quartz, limestone, granite or feldspar. The pore structure of aggregate particles may have a strong effect on autogenous shrinkage. Aggregate particles may contain water in coarse pores, which provides the “internal curing” for hydrating cement paste hence reducing autogenous shrinkage. Figure 2.6 indicates the relationship between W/C ratio, aggregate content and shrinkage. Figure 2.6: Effect of W/C ratio and aggregate content on shrinkage [36]

- 51. 29 2.3.2.8 Elastic Modulus of Aggregate Modulus of elasticity is the most important property of aggregate that directly influences drying shrinkage of concrete. When readily compressible aggregate is used, concrete will shrink as mush as neat cement, and that expanded shale leads to shrinkage more than that of ordinary aggregate. Steel aggregate on the other hand, leads to shrinkage less than that of ordinary concrete. The drying shrinkage of concrete increased 2.5 times [17] when an aggregate with high elastic modulus was substituted by an aggregate with low elastic modulus. 2.3.3 Differential Shrinkage It was mentioned earlier that the potential shrinkage of neat cement paste is restrained by the aggregate. In addition, some restraint arises also from non-uniform shrinkage within the concrete member itself. Moisture loss takes place only at the surface so that a moisture gradient is established in the concrete specimen, which is thus subjected to differential shrinkage. The potential shrinkage is compensated by the strains due to internal stresses, tensile near the surface and compressive in the core. When drying takes place in an unsymmetrical manner, warping (curling) can result. It may be useful to point out that the values of shrinkage generally quoted are those of free shrinkage, or potential shrinkage, that is, contraction unrestrained either internally or by external constraints on a structural member. In considering the effect of the constraining forces on the actual shrinkage, it is important to realize that the induced stresses are modified by relaxation, which may prevent the development of cracking.

- 52. 30 Because relaxation occurs only slowly, it may prevent cracking when shrinkage develops slowly; however, the same magnitude of shrinkage occurring rapidly may well induce cracking. It is shrinkage cracking that is of paramount interest. Because drying takes place at the surface of concrete, the magnitude of shrinkage varies considerably with the size and shape of the specimen, being a function of the surface/volume ratio. A part of the size effect may also be due to the pronounced carbonation shrinkage of small specimens. Thus, for practical purposes, shrinkage cannot be considered as purely an inherent property of concrete without reference to the size of the concrete member. Many investigations have, in fact, indicated an influence of the size of the specimen on shrinkage. The observed shrinkage decreases with an increase in the size of the specimen but, above some value, the size effect is small initially as shown in Figure 2.7. The shape of the specimen also appears to enter the picture but, as a first approximation, shrinkage can be expressed as a function of the volume/surface ratio of the specimen. There appears to be a linear relation between this ratio and the logarithm of shrinkage as shown in Figure 2.8. The effect of shape is secondary. I-shaped specimens exhibit less shrinkage than cylindrical ones of the same volume/surface ratio, the difference being 14 percent on the average [18]. The difference, which can be explained in terms of variation in the mean distance that the water has to travel to the surface, is thus not significant for design purposes.

- 53. 31 Figure 2.7: Relation between axial shrinkage and width of concrete prisms of square cross-section and length/width ratio of 4 [37] Figure 2.8: Relation between ultimate shrinkage and volume/surface ratio [18]

- 54. 32 2.3.4 Shrinkage-induced Cracking As mentioned in connection with differential shrinkage, the importance of shrinkage in structures is largely related to cracking. Strictly speaking, we are concerned with the cracking tendency because the advent or absence of cracking depends not only on the potential contraction but also on the extensibility of concrete, its strength, and its degree of restraint to the deformation that may lead to cracking. Restraint in the form of reinforcing bars or a gradient of stress increases extensibility of concrete in that it allows it to develop strain well beyond that corresponding to maximum stress. A high extensibility of concrete is generally desirable because it permits concrete to withstand greater volume changes. The schematic pattern of crack development when stress is relieved by creep is shown in Figure 2.9. Cracking can be avoided only if the stress induced by the free shrinkage strain, reduced by creep, is at all times smaller than the tensile strength of the concrete. Thus, time has two-fold effect: the strength increases, thereby reducing the danger of cracking but, on the other hand, the modulus of elasticity also increases so that the stress induced by a given shrinkage becomes larger. Furthermore, the creep relieves decreases with age so that the cracking tendency becomes greater. A minor practical point is that, if the cracks due to restrained shrinkage form at an early stage, and moisture subsequently has access to the crack, many of the cracks will become closed by autogenous healing. One of the most important factors in cracking is the water/cement ratio of the mix because its increase tends to increase shrinkage and, at the same time, to reduce the strength of the concrete. An increase in the cement content also increases shrinkage and, therefore, the cracking tendency, but the effect on strength is positive. This applies to drying shrinkage. Carbonation, although it produces shrinkage, reduces subsequent

- 55. 33 moisture movement, and therefore is advantageous from the standpoint of cracking tendency. On the other hand, the presence of clay in aggregate leads both to higher shrinkage and to greater cracking. The use of admixtures may influence the cracking tendency through interplay of effects on hardening, shrinkage, and creep. Specifically, retarders may allow more shrinkage to be accommodated in the form of plastic shrinkage and also probably increase the extensibility of concrete, and therefore reduce cracking. On the other hand, if concrete has attained rigidity too rapidly, it cannot accommodate the would-be plastic shrinkage and, having a low strength, cracks. The temperature at the time of placing determines the dimensions of concrete at the moment when it ceases to deform plastically. A subsequent drop in temperature will produce potential contraction. Thus, placing concrete in hot weather means a high cracking tendency. Steep temperature or moisture gradients produce severe internal restraints and thus represent a high cracking tendency. Likewise, restraint by the base of a member, or by other members, may lead to cracking. Figure 2.9: Schematic pattern of crack development when tensile stress due to restrained shrinkage is relieved by creep [33]

- 56. 34 2.3.5 Effect of Shrinkage Virtually all concrete is subject to some form of restraint, such as steel reinforcement, forms, subgrade, or adjacent members. Each of these forms of restraint involve the imposition of a gradually increasing tensile force on the concrete which may lead to time-dependent cracking, increases in deflection and a widening of existing cracks. The advent of shrinkage cracking depends on the degree of restraint to shrinkage, the extensibility and strength of the concrete in tension, tensile creep and the load induced tension existing in the member. Cracking can be avoided if the gradually increasing tensile stress induced by shrinkage, and reduced by creep, is at all times less than the tensile strength of the concrete. The existence of load induced tension in uncracked regions accelerates the formation of time-dependent cracking. The control of such cracking requires two important steps. First, the shrinkage-induced tension and the regions where shrinkage cracks are likely to develop must be recognized by the structural engineer. Second, an adequate quantity and distribution of anchored reinforcement must be included in these regions to ensure that the cracks remain fine and the structure remains serviceable. 2.3.6 Methods of Controlling Shrinkage Cracking Specific methods to properly control shrinkage cracking have been developed and researched. Conventional methods, which include proper material selection, mixture proportioning, and good construction techniques, can be used to a certain extent to control and limit the shrinkage cracking of concrete. Unfortunately, because these methods are hard to control, and environmental conditions can vary so much, the

- 57. 35 shrinkage cracking cannot be entirely prevented. For example, concrete in hot, dry, and windy conditions can have much higher rates of water evaporation, thus making them more susceptible to shrinkage cracking. Innovative methods of controlling shrinkage cracking have been found in literature and developed by numerous researches to help control and eliminate shrinkage cracking. These include using fiber-reinforced concrete, shrinkage-reducing admixtures, shrinkage-compensating concrete, and extensible concrete. The categories of methods are summarized in Table 2.2. Table 2.2: Methods of controlling drying shrinkage [31] Methods Description Conventional • Proper Material Selection o Aggregates o Cement type o Admixtures • Mixture Proportioning o Cement Content Innovative • Fiber Reinforcement o Polypropylene o Steel • Shrinkage-Compensating Concrete • Shrinkage-Reducing Admixtures • Extensible Concrete

- 58. 36 2.3.6.1 Conventional Method Shrinkage cracking in concrete is currently being controlled through conventional methods, which consist of the proper selection of materials and concrete mixtures, along with good construction techniques. 2.3.6.1.1 Aggregates The type of aggregate used in concrete mixtures, as well as the aggregate content, can influence the amount of shrinkage in concrete. The aggregate type was the most significant factor affecting when concrete cracked [19]. Specifically, limestone- aggregate concretes proved to be the most resistant to cracking, while Eau Claire river gravel had the shortest time-to-cracking of the aggregates tested. Burrows (1998) also studied the effect of the type of aggregate used on the drying shrinkage of concrete. Again, limestone was found to be one of the aggregates exhibiting the least drying shrinkage while, in the study, sandstone exhibited the highest amount of drying shrinkage. The amount of aggregate used in a concrete mixture can also help to reduce shrinkage. Research has shown that a higher aggregate content can help to reduce shrinkage. Table 2.3 shows the aggregate type related to drying shrinkage according to Burrows report in 1998.

- 59. 37 Table 2.3: Aggregate type related to drying shrinkage [18] Aggregate One-year shrinkage (percent) Sandstone 0.097 Basalt 0.068 Granite 0.063 Limestone 0.050 Quartz 0.040 2.3.6.1.2 Cement Content and Type The amount of cement proportioned in concrete mixtures has an impact on the amount of shrinkage that concrete will undergo. Specifically, concrete cracking has been more prevalent when higher cement contents have been used. Krauss and Rogalla, using a ring shrinkage test, found that cracking occurred sooner as the cement content of the concrete mixes was increased [19]. Water-cement ratio also influences shrinkage behavior in concrete. Krauss and Rogalla found that the concrete with more water shrinks and creeps more than concrete with less water, but it may not crack sooner because it has higher creep [19]. Burrows contends that although concrete mixes with lower water-cement ratios produce stronger concrete, that same concrete can be much more vulnerable to cracking. The type of cement used also plays an important role in reducing shrinkage cracking. Krauss and Rogalla noted that cements that are ground finer and have higher sulfate contents increase the early strength of concrete while also increasing the early modulus of elasticity and heat of hydration [19]. For example, Type III cement could increase the risk of cracking because of the rapid early strength gains.

- 60. 38 2.3.6.1.3 Admixtures Fly ash, silica fume, set retarders, and accelerators are all admixtures that have been investigated for shrinkage by a number of researchers. Fly ash has been found to reduce early concrete temperatures and the rate of strength gain, thus reducing concrete cracking. The process of using fly ash to replace cement is referred to as the creation of extensible concrete and is described in detail following this section. Silica fume, a by-product of silicon metal or ferrosilicon alloys in electric arc furnaces, has been found to increase the cracking of concrete. The silica fume product has an average fineness of about two orders of magnitude finer than Portland cement, which causes the bleeding rate of concrete to decrease, and the subsequent water loss resulting from evaporation cannot be replaced. Silica fume is found to be a problem with cracking tendency specifically when the concrete is not cured properly. Retarders have not been proven either to be the cause of concrete cracking or to help reduce the risk of thermal cracking. Plastic cracking could be caused by the addition of retarders, while retarders have also been found to reduce the risk of thermal cracking by reducing early heat of hydration in concrete.

- 61. 39 2.3.6.2 Innovative Method Because of the extreme variance of the conventional methods used to control drying shrinkage, innovative methods should be used to help reduce cracking tendencies of concrete. These include fiber-reinforced concrete, shrinkage-reducing admixtures, shrinkage-compensating concrete, and extensible concrete. 2.3.6.2.1 Fiber-Reinforced Concrete Many studies have shown that adding fibers to concrete significantly reduces shrinkage cracking. Various parameters that were investigated include the addition of fibers at low volumes as compared to high volumes, as well as the different types of fibers to be used. Steel fibers can affect the properties of concrete, but the reinforced properties depend on the percentage of fiber addition, the aspect ratio of the fibers, and the strength of the concrete paste. Longer fibers provide more strength but decrease workability. For this reason, fibers with an aspect ratio of less than 100 are commonly used. Steel fiber reinforced concrete has been shown to increase the tensile strength, flexural strength, and compressive strength of concrete through research. Tests have shown that steel fibers do not affect the shrinkage strain of concrete, but the fibers can reduce the amount of cracking associated with the shrinkage strain.

- 62. 40 Low volume of polypropylene fibers can significantly reduce the plastic shrinkage of concrete. For low-volume fiber reinforcement typically 0.1%-0.3% has little effect on the properties of the hardened concrete. However, high volumes of fiber, generally greater than 2%, can increase the ductility and toughness of concrete. At high volumes, polypropylene fibers can be used to prevent shrinkage cracking. The shrinkage stress produced in the concrete is transferred to the fibers, which can better withstand the tensile stresses than the concrete. 2.3.6.2.2 Shrinkage-Reducing Admixtures A great deal of research has been performed regarding the development of SRAs used to control shrinkage cracking of concrete. These chemical admixtures, which are added to concrete work by lowering the surface tension of the pore water inside hardened concrete. The pore water evaporates from capillary pores in the hardened concrete during drying, and the tension in the liquid is transferred to the capillary walls, resulting in shrinkage. Any stresses generated during drying are proportional to the surface tension of the pore water solution. This surface tension is lowered by SRAs, thus reducing the overall drying shrinkage. Therefore, there are fewer tendencies for shrinkage and resultant stress to occur in the concrete when the pore water initially evaporates. SRAs affect the nature of the pore water, rather than limiting or reducing the amount of water from concrete during drying.

- 63. 41 2.3.6.2.2 Shrinkage-Compensating Concrete Shrinkage-compensating concrete is an innovative material that causes expansion of concrete during curing, which in turn reduces the effects of drying shrinkage. If the expansion is properly restrained, the concrete will be subjected to compression the first few days after concrete placement. Although the shrinkage-compensating concrete will shrink as much as normal concrete once exposed to drying conditions, the net shrinkage will be negligible because the concrete started out with an initial expansion. The mechanism of expansion in the shrinkage-compensating concrete is a result of the early formation and stability of ettringite. The ettringite crystals need water to expand, and therefore, moist curing must provide this water, or else minimal expansion will result. 2.3.6.2.3 Extensible Concrete Extensible concrete is a term that refers to a combination of factors that are useful for reducing the cracking in concrete. Basically, some of the conventional materials and methods mentioned previously can be used in an innovative manner to achieve this type of behavior. A typical extensible concrete would have a high volume of fly ash, low cement content, and a high water-cement ratio. These factors would produce a low heat of hydration, thereby reducing thermal stresses in the concrete while also producing a low elastic modulus and high creep, minimizing shrinkage cracking.

- 64. 42 2.4 Creep of Concrete Creep of concrete, resulting from the action of a sustained stress, is a yielding of the concrete. It may be due partly to viscous flow of the cement-water paste, closure of internal voids and crystalline flow in aggregates, but it is believed that the major portion is caused by seepage of colloidal water from the gel that is formed by hydration of the cement. Although water may exist in the mass as chemically combined water, and as free water in the pores between the gel particles, neither of these is believed to be involved in creep. The rate of expulsion of the colloidal water is a function of the applied compressive stress and of the friction in the capillary channels. The greater the stress, the steeper the pressure gradient with resulting increase in rate of moisture expulsion and deformation. The phenomenon is closely associated with that of drying shrinkage. Creep is defined as the increase in strain under a sustained stress. There is an instantaneous strain on concrete which is called the “elastic” deformation when the sample is unloaded. It is observed that there is a gradual increase in strain for days after a stress has been applied to concrete. This is called the “creep” strain. Since this increase can be several times as large as the strain on loading, creep is of considerable importance in structural mechanics. The deformation of concrete with time is schematically shown in Figure 2.10. The rate of creep is relatively rapid at early ages after loading and then decreases gradually, until after a few years it becomes insignificant. Roughly, about one-fourth of the ultimate creep occurs within the first month or so, and one-half occurs within the first year.

- 65. 43 Figure 2.10: Typical strain-time plot of concrete under a sustained load and after release of load [16] Creep in concrete is a post-elastic phenomenon. In practice, drying shrinkage and viscoelastic behavior such as creep usually take place simultaneously. Considering the various combinations of loading, restraining, and humidity conditions, the following terms is defined: i. True or Basic Creep Defined as the creep that occurs under conditions that there is no drying shrinkage or moisture movement between concrete and ambient environment. ii. Specific Creep - Defined as creep strain per unit of applied stress. - Specific Creep = εcr / σ

- 66. 44 iii. Drying Creep - Is the additional creep that occurs when the specimen under load is also drying. iv. Creep Coefficient - Is defined as the ratio of creep strain to elastic coefficient. - Creep Coefficient = εcr / εE 2.4.1 Creep Behavior of Concrete Creep in concrete can have both positive as well as negative effects on the performance of concrete structures. On the positive side, creep can relieve stress concentrations induced by shrinkage, temperature changes, or the movement of supports. For indeterminate beam with two fixed ends, creep deformation will be very useful in reducing tensile stress caused by shrinkage and temperature variation. In some concrete structures, creep can do hard to the safety of the structures. Creep can lead to an excessive deflection of structural members, buckling or other serviceability problems, especially in high-rise building, eccentrically loaded columns and long bridges [8]. In mass concrete, creep may be a cause of cracking when a restrained concrete mass undergoes a cycle of temperature change due to the development of heat of hydration and subsequent cooling [8].

- 67. 45 2.4.2 Components of Creep Strain There are two components of creep strain which occur in a concrete member, recoverable creep and irrecoverable creep [30], as show in Figure 2.11. the recoverable component also know as delayed elastic strain εd(t), which is caused by the elastic aggregates acting on the viscous cement paste after the applied stress is removed. Figure 2.11: Recoverable and irrecoverable creep component [30] While the irrecoverable component, also can be referred as flow, εf(t). It is subdivided into rapid initial flow εfi(t), basic flow εfb(t) and drying flow εfd(t). Rapid initial flow happens in the first 24 hours after loading and is the remaining flow which develops gradually with time. While basic flow or basic creep is not dependent upon the loss of moisture from the concrete and will occur with concrete protected from drying.

- 68. 46 Meanwhile drying creep is the additional creep which occurs in a drying specimen. However, drying creep, like drying shrinkage, is dependent upon the loss of moisture from the concrete to its environment [31]. In normal structural engineering application, one does not distinguish between basic and drying creep [33]. Therefore, the creep strain can be expressed as [30] εf(t) = εd(t) + εf(t) or εf(t) = εd(t) + εfi(t) + εfb(t) + εfd(t) as illustrated in Figure 2.12. Figure 2.12: Creep components in a drying specimen [30]

- 69. 47 2.4.3 Factors Affecting Creep The magnitude of the creep depends upon several factors relating to the quality of the concrete such as the aggregate-cement ratio, water-cement ratio, kind of aggregate and its grading, composition and fineness of cement, and the age at time of loading. It also depends upon the intensity and duration of stress, moisture content of the concrete, the humidity of the ambient air, and the size of the mass. 2.4.3.1 Effect of Stress and Age When First Loaded The greater the degree of hydration of the cement at the time of load application, the lower the rate and total amount of creep. One explanation of this is that the expulsion of moisture from the gel becomes more difficult as the porosity is decreased through hydration. Since the extent of the hydration is indicated by the strength of a given concrete, it can be said that creep varies inversely as the strength. 2.4.3.2 Effect of Water-Cement Ratio and Mix Strength of concrete is determined by the water/cement ratio. The strength of concrete reduces with the increasing of water/cement ratio. Concrete experience higher creep due to higher water/cement ratio because the concrete has insufficient restraint due to the tension force induced in the concrete. A higher water-cement ratio increases the

- 70. 48 size of the pores in the paste structure, so that water may the more readily escape, and then under a sustained load the water of adsorption may be expelled more readily to cause a high rate of creep as shown in Figure 2.13. Figure 2.13: Effect of water-cement ratio on creep [34] 2.4.3.3 Effect of Composition and Fineness of Cement Cement is the most important factor in creep because the hydrated cement paste is the source of the phenomenon. The influence of cement is twofold: that arising from the physical and chemical properties of the cement. The composition of cement affects the creep primarily through its influence upon the degree of hydration. Slow-hardening cements such as low-heat Portland and Portland-pozzolan cements creep more than cements which hydrate more rapidly. Creep seems to be inversely proportional to the rapidly of hardening of the cement used. The more hardened the paste the more rigid it is and the lower its creep potential at a given applied stress.

- 71. 49 Figure 2.14: Creep in compression and tension for mass-cured concretes [34] Figure 2.14 indicates that in both tension and compression the creep of concrete made with low-heat cement is about one-third greater than for concrete made with normal cement. This serves to explain why low-heat Portland and Portland-pozzolan cements have served so effectively in relieving stresses in large dams as the mass cools and have shown superior resistance to cracking. 2.4.3.4 Effect of Character and Grading of Aggregate Aggregates play an important role in creep of concrete. Coarse aggregate reduces creep deformation by reducing the cement paste content and restraining the cement paste against contraction. Generally, concretes made with an aggregate, which is hard and dense and have low absorption and high modulus of elasticity, are desirable when low creep strain is needed.