Maintenance Reliability

•Transferir como PPTX, PDF•

2 gostaram•393 visualizações

Denunciar

Compartilhar

Denunciar

Compartilhar

Recomendados

Recomendados

Maintenance and reliability has taken great strides toward managing asset reliability by applying known best practices in maintenance and reliability finding that they can optimize reliability and reduce total cost and reduce risk by applying known best practices. However, if not most organizations are still trapped in the old way of thinking. Check out this awesome article.Advanced Maintenance And Reliability (Best Practices in Maintenance and Relia...

Advanced Maintenance And Reliability (Best Practices in Maintenance and Relia...Ricky Smith CMRP, CMRT

Performance based contracting (PBC) emerged as a new service model which is reshaping the acquisition, operation and maintenance of capital equipment. PBC is often referred to as performance based logistics in defense industry, or is called as power-by-the-hour in the airline industry. The focus of PBC is on the outcome of the system reliability performance, not materials and labors involved in the maintenance. This presentation introduces a novel quantitative approach to planning performance-based contracts in the presence of system usage uncertainty. We develop an analytical model to characterize the system availability by comprehending five key performance drivers: failure rate, usage variability, spare parts inventory, repair turn-around time, and system fleet population. This analytical insight into the system performance allows us to estimate the lifecycle cost by taking into account the design, manufacturing, maintenance and repair across the system lifetime. Two types of contracting schemes are examined under the cost minimization and the profit maximization. This presentation aims to provide theoretical guidance to facilitate the paradigm change as it shits from material based services to performance based contracting.Managing system reliability and maintenance under performance based contract ...

Managing system reliability and maintenance under performance based contract ...ASQ Reliability Division

Mais conteúdo relacionado

Destaque

Maintenance and reliability has taken great strides toward managing asset reliability by applying known best practices in maintenance and reliability finding that they can optimize reliability and reduce total cost and reduce risk by applying known best practices. However, if not most organizations are still trapped in the old way of thinking. Check out this awesome article.Advanced Maintenance And Reliability (Best Practices in Maintenance and Relia...

Advanced Maintenance And Reliability (Best Practices in Maintenance and Relia...Ricky Smith CMRP, CMRT

Performance based contracting (PBC) emerged as a new service model which is reshaping the acquisition, operation and maintenance of capital equipment. PBC is often referred to as performance based logistics in defense industry, or is called as power-by-the-hour in the airline industry. The focus of PBC is on the outcome of the system reliability performance, not materials and labors involved in the maintenance. This presentation introduces a novel quantitative approach to planning performance-based contracts in the presence of system usage uncertainty. We develop an analytical model to characterize the system availability by comprehending five key performance drivers: failure rate, usage variability, spare parts inventory, repair turn-around time, and system fleet population. This analytical insight into the system performance allows us to estimate the lifecycle cost by taking into account the design, manufacturing, maintenance and repair across the system lifetime. Two types of contracting schemes are examined under the cost minimization and the profit maximization. This presentation aims to provide theoretical guidance to facilitate the paradigm change as it shits from material based services to performance based contracting.Managing system reliability and maintenance under performance based contract ...

Managing system reliability and maintenance under performance based contract ...ASQ Reliability Division

Destaque (20)

Reliability Maintenance Engineering 1 - 4 Estimating Reliability

Reliability Maintenance Engineering 1 - 4 Estimating Reliability

Advanced Maintenance And Reliability (Best Practices in Maintenance and Relia...

Advanced Maintenance And Reliability (Best Practices in Maintenance and Relia...

Maintenance Reliability and the Internet of Things: What's your strategy?

Maintenance Reliability and the Internet of Things: What's your strategy?

Reliability Maintenance Engineering 2 - 4 Purpose and Equipment

Reliability Maintenance Engineering 2 - 4 Purpose and Equipment

Managing system reliability and maintenance under performance based contract ...

Managing system reliability and maintenance under performance based contract ...

Certified Maintenance & Reliability Professional Study Guide Notes

Certified Maintenance & Reliability Professional Study Guide Notes

Reliability Maintenance Engineering 2 - 3 Measuring Maintainability

Reliability Maintenance Engineering 2 - 3 Measuring Maintainability

Three primary steps in maintenance reliability engineering

Three primary steps in maintenance reliability engineering

Introduction to Reliability and Maintenance Management

Introduction to Reliability and Maintenance Management

Maximo KPI Maintenance & Asset Reliability Support Workshop IMC 2013 presenta...

Maximo KPI Maintenance & Asset Reliability Support Workshop IMC 2013 presenta...

Reliability and Maintenance in production Management

Reliability and Maintenance in production Management

Semelhante a Maintenance Reliability

1) Solution to Deltek Acumen Fuse import issue resulting in incorrect translation of original and remaining durations.

2) When imported durations come in incorrectly, all the metrics using duration as a variable will come out wrong.

3) We will troubleshoot and resolve this problem in this article.

Rufran (043015)043015 Rufran's Acumen Fuse Tips and Tricks 01-15 (Duration Translation Issue)

043015 Rufran's Acumen Fuse Tips and Tricks 01-15 (Duration Translation Issue)PM SOLUTION PRO| Risk-based Management and Services Inc.

Semelhante a Maintenance Reliability (20)

043015 Rufran's Acumen Fuse Tips and Tricks 01-15 (Duration Translation Issue)

043015 Rufran's Acumen Fuse Tips and Tricks 01-15 (Duration Translation Issue)

Risk management in complex changeovers through cfmea

Risk management in complex changeovers through cfmea

Maintenance Reliability

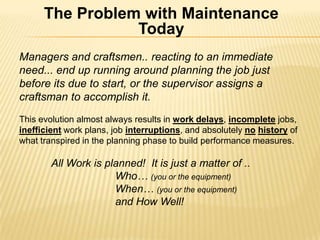

- 1. The Problem with Maintenance Today Managers and craftsmen.. reacting to an immediate need... end up running around planning the job just before its due to start, or the supervisor assigns a craftsman to accomplish it. This evolution almost always results in work delays, incompletejobs, inefficient work plans, job interruptions, and absolutely nohistoryof what transpired in the planning phase to build performance measures. All Work is planned! It is just a matter of .. Who… (you or the equipment) When… (you or the equipment) and How Well!

- 2. Basic Maintenance Philosophies Reactive Maintenance - Run to Failure Preventive Maintenance - Interval or Time Based Predictive Maintenance- Condition Based Proactive Maintenance - Root Cause Based

- 3. Potential to Hard Failure Curve Changes in Vibration P-F interval 1-9 months Point where failure starts to occur Wear Debris in oil P-F interval 1-6 months IR Thermography P-F interval 3-12 weeks Audible noise P-F interval 1-4 weeks P1 P2 P3 Heat by touch P-F interval 1-5 days P = Potential Failure P4 P5 F = Failure F

- 4. The P-F Incidents on Scrubber Failure Example: Circulation pump failed. Unknown failure at this point. Supplier scheduled and performed PM on scrubber system-identified problems. Material had a long lead time, ordered all necessary material/supplies to correct problems. Scheduling down time to perform repairs. Circulation tank filling up with sludge & circulation pump seal leaking. Build up of material on Plater is accumulating more than normal. P1 P3 P2 Scrubber ventilation decreased beyond functional levels-Shut Down Discovered the circulating pump quit working. Scrubber and plater continue to run. Ordered new pump-long lead time. P = Potential Failure P4 P5 F0 Increased smell emitting from plater material F = Failure F1

- 5. Events and Reason the Scrubber Failed Example: Scheduled and performed PM on scrubber. Identified problems and material. Material had a long lead time, ordered and received all necessary material/supplies to correct problems. Scheduling supplier to perform removal of material. Scrubber ventilation decreased beyond functional levels-We learned that the machine will run to failure but due to the working conditions, the machine had to be shut down and repaired. We must perform repairs between P5 and F0. P1 P2 P3 P4 Points where failure starts to occur P1 to P3 P5 Predictive Tools Used => Air Flow Meter F0 F1 W-1 W-2 W-4 W-5 W-6 W-? W-3 W+1 Timeline Towards Failure Future Work Execution

- 7. Asset Reliability Foundation Key elements for building a good foundation. Each company will need to build the foundation to their needs and requirements. 100% Reliability 90% OEE MTBF & MTTR 80% Restoration / Overhaul Predictive Maintenance 70% Autonomous Maintenance Maintenance Planning Maintenance Scheduling 60% Maintenance CMMS 40% Leadership Buy-IN Maintenance Training Establish Maintenance Team

- 8. Asset Reliability Foundation 100% Reliability 90% OEE MTBF & MTTR 80% Restoration / Overhaul Predictive Maintenance 70% Autonomous Maintenance Maintenance Planning Maintenance Scheduling 60% Maintenance CMMS 40% Leadership Buy-IN Maintenance Training Establish Maintenance Team

- 9. Requirements for Success Good Planning Complete Parts Lists Good Scheduling High % of Scheduled Work High Schedule Compliance Integrated Processes Purchasing, Stores & Work Management Good Control System Manual or CMMS

- 10. How to get it done! Significantly Expand the PdM initiatives Re-institutionalized the use of the CMMS Focused on Planning/Scheduling the Right Work (PM, PdM, Results) Conducted RCM analysis on strategic systems Optimized and integrated their PM & PdMStrategies Integrated Master Scheduling