Tekni Plex 051205

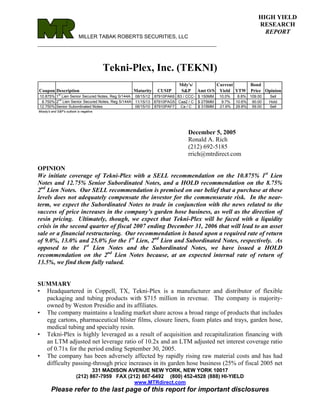

- 1. HIGH YIELD RESEARCH REPORT MILLER TABAK ROBERTS SECURITIES, LLC _________________________________________________________ Tekni-Plex, Inc. (TEKNI) Mdy's/ Current Bond Coupon Description Maturity CUSIP S&P Amt O/S Yield YTW Price Opinion st 10.875% 1 Lien Senior Secured Notes, Reg S/144A 08/15/12 87910PAK6 B3 / CCC- $ 150MM 10.0% 8.8% 109.00 Sell nd 8.750% 2 Lien Senior Secured Notes, Reg S/144A 11/15/13 87910PAG5 Caa2 / C $ 275MM 9.7% 10.6% 90.00 Hold 12.750% Senior Subordinated Notes 06/15/10 87910PAF7 Ca / C $ 315MM 21.6% 29.8% 59.00 Sell Moody's and S&P's outlook is negative. December 5, 2005 Ronald A. Rich (212) 692-5185 rrich@mtrdirect.com OPINION We initiate coverage of Tekni-Plex with a SELL recommendation on the 10.875% 1st Lien Notes and 12.75% Senior Subordinated Notes, and a HOLD recommendation on the 8.75% 2nd Lien Notes. Our SELL recommendation is premised on our belief that a purchase at these levels does not adequately compensate the investor for the commensurate risk. In the near- term, we expect the Subordinated Notes to trade in conjunction with the news related to the success of price increases in the company’s garden hose business, as well as the direction of resin pricing. Ultimately, though, we expect that Tekni-Plex will be faced with a liquidity crisis in the second quarter of fiscal 2007 ending December 31, 2006 that will lead to an asset sale or a financial restructuring. Our recommendation is based upon a required rate of return of 9.0%, 13.0% and 25.0% for the 1st Lien, 2nd Lien and Subordinated Notes, respectively. As opposed to the 1st Lien Notes and the Subordinated Notes, we have issued a HOLD recommendation on the 2nd Lien Notes because, at an expected internal rate of return of 13.5%, we find them fully valued. SUMMARY • Headquartered in Coppell, TX, Tekni-Plex is a manufacturer and distributor of flexible packaging and tubing products with $715 million in revenue. The company is majority- owned by Weston Presidio and its affiliates. • The company maintains a leading market share across a broad range of products that includes egg cartons, pharmaceutical blister films, closure liners, foam plates and trays, garden hose, medical tubing and specialty resin. • Tekni-Plex is highly leveraged as a result of acquisition and recapitalization financing with an LTM adjusted net leverage ratio of 10.2x and an LTM adjusted net interest coverage ratio of 0.71x for the period ending September 30, 2005. • The company has been adversely affected by rapidly rising raw material costs and has had difficulty passing-through price increases in its garden hose business (25% of fiscal 2005 net 331 MADISON AVENUE NEW YORK, NEW YORK 10017 (212) 867-7959 FAX (212) 867-6492 (800) 452-4528 (888) HI-YIELD www.MTRdirect.com Please refer to the last page of this report for important disclosures

- 2. sales) due to a concentrated customer base. Adjusted EBITDA for the fiscal year-ended 2005 was $72.4 million, down from $118.0 million in fiscal 2003. • Liquidity at the end of the first quarter of fiscal 2006 was $100.4 million, comprised of $40.4 million of cash and $60.0 million of revolver availability. We project that Tekni-Plex completes fiscal 2006 with $6.8 million in liquidity. On a projected rebounded adjusted EBITDA base of $91.1 million in fiscal 2007, the company would still be faced with supporting an estimated $90.0 million in cash interest payments and $20.0 million in capital expenditures. We project Tekni-Plex to run out of liquidity in the second quarter of fiscal 2007. • While we anticipate a liquidity crisis, we also foresee a fundamental turnaround in Tekni- Plex’s business given a backdrop of moderate success in pricing pass-throughs in its garden hose business and an abating of raw material costs. Company options to bridge the liquidity gap would include borrowing additional debt, selling assets, as well as structuring some form of financing with Weston Presidio. We have estimated the likelihood of a fiscal 2007 restructuring at 75%. • Given our evaluation of the current risks associated with Tekni-Plex’s turnaround, our recommendations for Tekni-Plex’s debt securities are based upon required returns of 9.0%, 13.0% and 25.0% for the 10.875% Senior Secured Notes, 8.75% Senior Secured Notes and 12.75% Senior Subordinated Notes, respectively. BUSINESS OVERVIEW Headquartered in Coppell, TX, Tekni-Plex (“Tekni” or the “Company”) is an international manufacturer of packaging, packaging products and plastics materials, primarily for the food, healthcare and consumer markets. With operations in the United States, Europe, Argentina and Canada, Tekni employs approximately 3,200 employees, about a third of which are represented by labor unions. Since its purchase in March 1994 by Dr. F. Patrick Smith and a group of investors, Tekni-Plex has acquired 10 companies and added a number of product lines (see Figure 2). For the twelve-month period ended September 30, 2005, Tekni-Plex posted an adjusted EBITDA of $67.8 million on a revenue base of $714.8 million. The Company currently reports its results through three Figure 1 business segments: Packaging (50% of net sales), Tubing TEKNI-PLEX Products (30% of net sales) and Other, which reports Tekni’s Market Share materials compounding business. The Packaging segment Packaging Position currently includes egg cartons, pharmaceutical blister films, Foam Egg Carton 1 Pharmaceutical Blister Films 1 poultry and meat processing trays, closure liners, aerosol and Aerosol & Pump Components 1 pump packaging components, and foam plates; Tubing Closure Liners 1 Poultry & Meat Processor Trays 2 Products encompasses garden, irrigation, vacuum and pool Tubing hose, as well as medical tubing. Tekni’s Other business Garden and Irrigation Hose 1 Vinyl Medical Tubing 1 segment produces recycled polyethylene terepthalate (“PET”), Other specialty resins and vinyl compounds for downstream Vinyl Medical Device Materials 1 Source: Company reports. converters. In practically all of its product lines, Tekni maintains a leading share of the market (see Figure 1). Tekni-Plex is currently struggling with a highly leveraged balance sheet, soaring feedstock costs, a limited ability to pass-through pricing in its garden hose business (25% of net sales), and soon to be reduced liquidity. Much of the Company’s current debt load was incurred in connection 2

- 3. with the March 1998 acquisition of PureTec Corporation and the June 2000 recapitalization of the Company. Figure 2 TEKNI-PLEX Growth Through Acquisition PRICE DATE BUSINESS LOCATION PRODUCTS ($ millions) ACQUIRED General Felt Products, Laminated closure liners division of Standard Brooklyn, NY for pharmaceutical and NA 1967 Packaging Corporation food industries Hargro Flexible Packaging Corp.; Packaging materials for Flemington, NJ $ 7.5 December 1995 Flemington plant and pharmaceutical industry business. Dolco Packaging Corp. Sherman Oaks, CA Foam egg processor trays $ 39.0 February 1996 Food and electronics PurePlast Inc.; Ontario Cambridge, Ontario, packaging, as well as, $ 2.3 July 1997 facility Canada vinyl sheet for pharmaceutical industry Garden and irrigation hose, precision tubing and gaskets for aerosol packaging industry, vinyl PureTec Corporation Ridgefield, NJ $ 325.0 March 1998 medical tubing, and vinyl compounds for the production of medical devices Tri-Seal International, Extruded and co-extruded Blauvelt, NY $ 20.2 January 1999 Inc.; assets. capliners and seals Disposable medical tubing Natvar; assets. Clayton, NC $ 26.0 April 1999 and electrical sheathing Super Plastics division of Longueuil, Quebec, Garden hose $ 10.2 October 2000 RCR International Inc. Canada Swan Hose division of Mark IV Industries, Inc.; Bucyrus, OH Garden hose $ 64.2 October 2001 assets. Polystyrene foam plates, Elm Packaging Memphis, TN bowls, and meat and $ 16.4 July 2002 Company, assets bakery trays Genpak; carton Glens Falls, NY Egg cartons $ 5.8 July 2004 business. Source: Company reports. 3

- 4. INDUSTRY The packaging industry is very diverse, comprised of companies that pursue distinct lines of business, such as metal containers, glass containers, flexible packaging, food service packaging, protective packaging and dispensing closures. Each segment is typically made up of a unique group of competitors that employs specialized machinery, services distinct customers, and utilizes different raw materials. Barriers to entry, innovation cycles, product differentiation, competitive dynamics, and pricing power also vary tremendously among the various packaging segments. Flexible Packaging The flexible packaging Figure 3 industry has evolved TEKNI-PLEX VALUE CHAIN over the past 25 years as Producers and Select Consumers an alternative to rigid PACKAGING TUBING PRODUCTS packaging. As plastics have become more Dow Chemical sophisticated, flexible ExxonMobil Occidental Chemical FEEDSTOCK Chevron Phillips Chemical Georgia Gulf packaging companies Shell Chemicals have been able to Nova Chemicals provide product manufacturers with packaging that has allowed them to further differentiate their Dow Chemical Shintech RESIN Total Petrochemicals Occidental Chemical products to the consumer Nova Chemicals Formosa through package Chevron Phillips Chemical Georgia Gulf graphics, added shelf life and increased package convenience. According to the Flexible CONVERTER TEKNI-PLEX Packaging Association, the United States market for flexible packaging was approximately $21.3 billion in 2004, and had 3M Pharmaceuticals grown at a compounded Pfizer Home Depot Eli Lilly Wal-Mart annual growth rate of END-MARKET Boston Scientific Lowe's 3.9% over the prior ten Kraft Foods Target Cal-Maine Foods Ace Hardware years. Rose Acres MoArk A subset of specialty packaging, flexible Source: Company reports and MTR. packaging is used for a variety of applications, from food wrappers to mattress covers. In industrial markets, stretch and shrink films are often used instead of corrugated boxes and metal strapping to unitize, bundle and protect items during shipping and storage. The diversity of applications has led to the development of a fragmented industry, with the top ten companies accounting for less than 50% of sales. With most packaging converters possessing less market power than their substantially larger suppliers and customers, consolidation is likely, especially within today’s compressed 4

- 5. margin environment resulting from rapidly rising raw material costs. Figure 3 delineates Tekni- Plex’s position along the value chain, placing the company between considerably larger suppliers and customers. Competitors to Tekni-Plex include Pactiv, Bemis and Sealed Air. Discussed later in Macro Drivers, flexible packaging companies use plastic resins in the manufacture of their products. Resins, which utilize crude oil and natural gas in their formation, have experienced substantial price increases along with rising energy prices. With resin accounting for approximately 50% of flexible packaging cost of goods sold, converters have worked to pass-through price increases to their customer base with varied success. Foodservice Packaging Foodservice packaging refers to packaging designed and manufactured for customers in the food industry that process and prepare food for consumption, also known as food packers and processors; it also includes customers in the food distribution business such as wholesalers and supermarkets. With estimated annual sales exceeding $10 billion in the United States, the foodservice packaging industry produces products that protect food during distribution, assist retailers in merchandising food, and help customers prepare and serve meals at home. Foodservice packaging includes everyday items such as egg cartons, meat processing trays, clamshell containers and fast-food carryout trays. Historical growth rates of this segment have exceeded 5%, driven by evolving consumer dietary patterns. PRODUCT LINES While Tekni-Plex manufactures a broad line of products (see Figures 5,6), we have chosen to focus on its garden hose and egg carton lines due to the material nature of their businesses, their shared challenges, and the varied success that Tekni-Plex has had in dealing with each within the current environment. Garden Hose Tekni-Plex established its leadership position in the garden hose market through the acquisitions of PureTec Corporation ($345 million in sales), the Super Plastics division of RCR International, and the Swan Hose division of Mark IV Industries. For the year ending July 2, 2005, garden hose net sales of $179.5 million comprised 25.7% of Tekni’s net sales and 86.5% of Tubing Products net sales. We estimate its gross contribution for the same period to be minimal at approximately $2 million, as compared with an estimated $19 million in fiscal 2004 and $51 million in fiscal 2003. Construction. Hose, as compared with tubing, is Figure 4 considered a more complex structure, usually consisting of three layers: an inner liner (the tube itself), a reinforcement layer and an outer jacket (see Figure 4). The raw materials that make up these structural elements include recycled polyvinyl chloride (“PVC”) for the inner liner, nylon (feedstock is polypropylene) for the reinforcement layer and plasticizer (a resin additive is used to Source: Ajay Industrial. create flexibility; feedstock is natural gas) for the outer coating. Additional additives are used to produce color in the hose, as well as resistance to abrasion and sunlight. Other raw materials that comprise the final product are used to make 5

- 6. couplings and packaging. On the whole, resin and plasticizer account for approximately 50% of total raw material costs. Product Differentiation. Manufacturers of garden hose differentiate their hose through a combination of quality and benefits. High quality hose has synthetic rubber mixed with the PVC used for the inner liner, employs a reinforcement layer around the inner tube to prevent bursting, and has fittings made of brass. From a benefits perspective, quality hose is very flexible and seldom kinks. While not every consumer is sophisticated or caring enough to vet these attributes, most consumers typically focus on price, diameter and length of hose. In speaking with the retail community, we get the sense that brand is practically irrelevant in the consumer’s purchase decision. Customer Concentration. According to the 2003 National Gardening Survey, home centers, such as Home Depot and Lowe’s, have become the most important distribution channel in the lawn and garden products industry. Industry participants have estimated that big-box retailers comprise 68% of Tekni’s garden hose sales, with Home Depot and Wal-Mart accounting for 45%. Customer concentration has been an extremely important component of Tekni’s financial problems. Well aware of the rising cost of petrochemical-based raw materials, large retailers have nevertheless resisted price increase pass-throughs. Their success in doing so is somewhat surprising given that Tekni-Plex is one of only two major domestic producers of garden hose in a market that is not currently impacted by imports (see Garden Hose: Imports). Figure 5 TEKNI-PLEX Product Lines EGG CARTONS GARDEN HOSE BLISTER FILMS FOAM PLATES MEDICAL TUBING CLOSURE LINERS Source: Company reports. 6

- 7. Figure 6 TEKNI-PLEX Business Description SEGMENT PRODUCT PRODUCT CHARACTERISTICS SALES CHANNEL CUSTOMERS COMPETITION NOTES SALES Somewhat Thermoformed foam polystyrene seasonal with packaging offers a combination of Pactiv weighting on fiscal Most domestic egg Foam Egg Cartons high strength, minimum material Direct sales force manufactures pulp- Q2 and Q3. Higher packagers. content and superior moisture based egg cartons. margins than other barrier performance. packaging product lines. Transparent, high-barrier blister packaging is primarily used to Global network of protect drugs from moisture vapor Two main sales and infiltration and dehydrating. Blister Major pharmaceutical competitors: Pharmaceutical Blister Films marketing packaging is preferred when companies. Pactiv, Klockner personnel on six dispenser handling can affect shelf Pentaplast. continents. like or drug efficacy, or when unit dose packaging is Thermoformed foam polystyrene packaging offers a combination of Pactiv and Formpac Poultry and Meat Processor high strength, minimum material Poultry industry. division of W.R. Trays content and superior moisture Grace barrier performance. PACKAGING $ 352MM Selig. Two principal Packagers of Closure liners perfect the seal competitors in North pharmaceutical, Closure Liners between a container and its Direct sales force America, but also healthcare and food closure, i.e. a bottle and its cap. compete with products. several smaller companies. Dip tubes which transmit contents of the container to the nozzle. Manufacturers of aerosol valves, Rubber-based valve gaskets that Customers moving Aerosol and Pump Packaging dispenser pumps and control the release of product from Direct sales force to internal Components writing instruments the container. production. such as AptarGroup Writing instrument products such and Rexam. as pen barrels, ink tubing and ink reservoirs for felt-tip pens. Thermoformed foam polystyrene Consumer, agricultural disposable plates, bowls, and Pactiv. Foam Plates and foodservice hinged-lid containers, as well as, Numerous. industries. agricultural packaging products. Retailers such as home centers, hardware Highly seasonal High quality lines that utilize Direct sales force cooperatives, food, Teknor Apex with 75% of sales Garden and Irrigation Hose medical-grade plastics and brass and independent auto, drug and mass Ames True Temper occurring in spring couplings. representatives. merchandising chains Flexon and early summer and catalog companies months. TUBING throughout the U.S. $ 225MM and Canada. Kelcourt Plastics. Customers High quality, close tolerance tubing Manufacturers of Medical Tubing Direct sales force upgrading for surgical procedures. medical devices. machinery and increasing capacity. Used for floor coverings, automotive sealants and Direct sales force Teknor Apex. Recycled PET, Vinyl OTHER adhesives, coil coatings, plastisol and independent Large chemical $ 138MM Compounds, Specialty Resins and medical device compounding, representatives. companies. and vinyl packaging Source: Company reports and MTR. Pricing. Wholesale pricing on garden hose has historically been established one time per year in the summer months, and is scheduled to take effect the following January 1st. According to Tekni-Plex, the actual setting of price is not contractual (nor are volumes), but is more of a gentleman’s agreement with customers. Price increases have typically ranged between 3% and 5%, with some years having no increase. On October 7, 2005, Teknor Apex, Tekni’s primary garden hose competitor, announced that, effective January 1, 2006, it would institute a 7.5% surcharge on its standard annual price increase, citing rapidly rising raw material, energy and transportation costs (see Macro Drivers). Teknor Apex’s pricing action and its subsequent acceptance is difficult to confirm, given the secretive nature of retail buyers. Until a recent 7

- 8. change in market approach discussed on its fourth quarter fiscal 2005 conference call, Tekni had appeared unwilling to increase prices, fearful of losing market share. Given the dire nature of its liquidity situation, the Company has stated that it is going to market with a double-digit price increase, as well as a potential second increase, ranging between 7.5% and 10.0%, effective January 1, 2006. The announced increases have evidently led to some loss of market share; the amount is unknown to the public. Future price increases may result in further market share loss. Competition. It has been estimated by market participants that Tekni-Plex has historically had a 55% share of the garden hose market, with Teknor Apex holding a 30% share. Teknor Apex, a compounder of PVC and engineering resins headquartered in Pawtucket, R.I., is estimated to have generated $500 million of revenue in fiscal 2004, with approximately $95 million derived from the sale of garden hose. Other competitors in the marketplace include Ames True Temper and Flexon, based in New Jersey. Imports. Imports comprise a very small portion of domestic market share, currently estimated at approximately 3%. Reasons given by market participants for the low level of imports include insufficient quality, minimal cost savings due to a non-labor intensive production process, the difficulty associated with refilling retail inventory channels upon short notice, and the offset of product price savings by transportation costs. On the other hand, we held a conversation with the garden products buyer of a second-tier retail chain who revealed that imports will comprise 40% of the chain’s upcoming year’s garden hose line. While the buyer believes that domestic quality is superior to that of imports and that imports are not an appropriate substitute for high-end hose, he believes that overseas-produced mid-range hose is of sufficient quality and price point to warrant importation. He further commented that the quality of product produced by China is getting increasingly better. Citing hose endings as a category that is no longer produced domestically, a sweeping change from just five years prior, he believes that garden hose will eventually be greatly trade impacted. Recounting a recent trip to China, he spoke of factories the size of football fields and numerous lines of new hose extrusion machinery. The disparity between domestic and China recycled PVC pricing may widen in the coming years given our view of China’s changing raw material landscape. Currently, China lacks a developed waste management industry, which impedes the supply of recycled PVC, garden hose’s main raw material. As China continues to bring additional prime PVC capacity online (see Macro Drivers) and builds-out its waste management infrastructure, the difference between domestic and foreign raw material pricing may widen to the point where the importation of garden hose makes economic sense. While there is no indication that the garden hose supply landscape will change overnight, the macro picture may depress reorganization values in the event of a bankruptcy filing or limit the interest of potential buyers should an asset sale be pursued. An asset sale of the garden hose business, though, would be difficult given that it is not discrete, but rather shares physical plant space with Tekni’s materials compounding business. Seasonality. The sale of garden hose is an extremely seasonal business with approximately 70% of sales occurring in the spring and early summer (Tekni’s third and fourth fiscal quarters). Maintaining service levels requires year-round production of garden hose and drives fluctuations in working capital accounts. Tekni inventory levels typically reach their low point in the fourth 8

- 9. fiscal quarter, the end of the main selling season, and then build to their peak in the second fiscal quarter in advance of the beginning of the selling season. Accounts receivable also move in conjunction with these cycles, reaching a peak in the fourth fiscal quarter and a trough in the second fiscal quarter. Egg Cartons Tekni-Plex’s egg carton business is a fundamentally strong business. Manufactured and sold by Tekni’s Dolco Packaging division (merged into Tekni-Plex in August 1997), egg cartons accounted for 17% of total net sales and 36% of Packaging net sales in fiscal 2003 (fiscal 2004 is not representative), with sales of cartons that year reaching $104 million. Prior to the recent run- up in raw material costs, gross margins had typically ranged between 30% and 35%, higher than other Packaging segment products (~25%). We estimate LTM adjusted EBITDA for the period ending September 30, 2005 at $20.8 million. Product Differentiation. Tekni-Plex manufactures its egg cartons from expandable polystyrene, producing a foam carton, versus other cartons that are pulp or molded-fiber based. Each has its own distinct characteristics and market following. Foam egg cartons typically run better on automated packaging equipment resulting in fewer broken eggs, are easier to print on and more visually appealing, and can be colorized to enhance marketing. Pulp-based egg cartons, a favorite of environmentalists, absorb moisture from the egg (extending freshness) and are thought to deliver fewer broken eggs to the retail store. Estimated at 55%, the foam egg carton market share has gradually increased, taking share from pulp-based egg cartons. Pricing. As with most products in Tekni’s Packaging segment, foam egg cartons are made from polystyrene. Along with other petrochemical-based raw materials, polystyrene pricing has been increasing over the past two years (see Figure 8). Within this environment, Tekni-Plex has been successful in passing through price increases to its customer base. Pricing is typically done at the time of a customer order and does not involve long-term contracts. The magnitude of the pass-throughs is intended to maintain Tekni’s gross profit dollar, as opposed to its gross margin. The Company’s success in this area, as opposed to its garden hose line, appears to be a reflection of 1) a superior product, 2) customer acceptance, 3) competitor practice, and 4) high Tekni production capacity utilization. While probably more diverse than that of the Company’s garden hose business, Tekni’s egg carton customer base is comprised of large egg farm/packagers such as Cal-Maine Foods, Rose Acres and MoArk. Competition. Tekni-Plex is currently the leading U.S. producer of foam egg cartons, with approximately 40% of the egg carton market and more than 80% of the foam egg carton market. Pactiv, a leading flexible packaging company known for brands such as Hefty and Baggies, is the top producer of pulp-based egg cartons. Together, the two companies represent a duopoly in the egg carton market. Recently, Hartmann of Denmark has entered the North America market with limited initial success. Seasonality. Egg demand, and thus egg carton demand, is somewhat seasonal in nature. Demand typically increases over Thanksgiving, Christmas, New Year’s, the Superbowl and Easter. This seasonality does not translate into a meaningful variance in Tekni’s egg carton sales because the Company is currently producing at capacity. 9

- 10. MACRO DRIVERS Due to the Company’s inability to pass through pricing in its garden hose line, Tekni-Plex has been greatly affected by the rise in pricing of petrochemicals and their derivative products. The following section will focus on the two resins which feed the majority of Tekni-Plex’s businesses and the dynamics that drive their pricing mechanism, and in turn, Tekni-Plex’s near-term future. Introduction Plastics are polymers (poly-styrene, poly-vinyl chloride) that are built up from monomers, which are derived from crude oil and natural gas (see Figure 7). Polymers that have been dried and shaped into pellets are referred to as plastic resins. These resins are further treated in plastics processing facilities to produce different physical characteristics in the material, such as strength, toughness and flexibility. Resins comprise a very large portion of Tekni-Plex’s cost of goods sold. On a historical basis, resins have typically made up 98% of Tekni-Plex’s cost of raw materials, which in turn, have accounted for 64% of Packaging cost of goods sold. Given that resin prices have dramatically increased, this percentage is most likely higher. Figure 7 TEKNI-PLEX Raw Material Value Chain PACKAGING TUBING PRODUCTS FEEDSTOCK CRUDE OIL NATURAL GAS CHEMICALS BENZENE ETHYLENE CHLORINE ETHYLENE MONOMER STYRENE VINYL CHLORIDE MONOMER POLYMER RESIN POLYSTYRENE POLYVINYL CHLORIDE Egg Cartons Garden Hose TEKNI-PLEX PRODUCTS Food Trays Medical Tubing Flexible Packaging Blister Packaging Source: Company reports and MTR. Polystyrene The majority of Tekni-Plex’s packaging segment revenue is derived from the sale of products that use polystyrene as their primary raw material input. These products include foam egg cartons, poultry and meat processor trays, and foam plates. Structurally, polystyrene is a molecular chain of styrene monomer, which is formed through the processing of benzene and ethylene. Benzene is a natural constituent of crude oil, but it is usually synthesized from other compounds present in petroleum. 10

- 11. Pricing. As can be readily Figure 8 deduced, the cost of producing POLYSTYRENE vs. LIGHT SWEET CRUDE OIL polystyrene is related to the cost PRICING of crude oil, though its selling 85 70 Lt. Swt. Crude Oil ($/barrel) price is another matter. As with Polystyrene (cents/lb) 80 60 most downstream products, the 75 70 50 pricing of polystyrene is subject 65 40 to supply/demand dynamics 60 that can be disconnected from 55 30 those affecting its feedstock. 50 20 Polystyrene pricing has been on 03 03 03 03 04 04 04 04 05 05 05 05 06 1Q 2Q 3Q 4Q 1Q 2Q 3Q 4Q 1Q 2Q 3Q 4Q 1Q an uptrend over the past three Polystyrene Lt. Sweet Crude Oil years, rising from 57 cents per pound in the first quarter of * X-axis reflects Company's fiscal calendar. Source: Plastics News (Crystal Injection GP) and NYMEX. fiscal 2003 to an estimated average price of 88 cents per pound in the second quarter of fiscal 2006 (see Figure 8). Recent announcements of price increases include 5 cents, 6 cents and 5 cents commencing October 1, 2005, November 1, 2005 and November 15, 2005, respectively. With a correlation of 0.95 (statistical measure by which 1.00 is Figure 9 perfect correlation), the pricing movement of polystyrene parallels FEEDSTOCK that of crude oil (see Figure 9). We have chosen not to use this CORRELATION Fiscal Lt.Swt.Crude PS * correlation for polystyrene forecasting purposes due to our belief Period ($/barrel) (cts/lb) that the NYMEX Light Sweet Crude Oil futures contracts pricing 1Q03 28.3 56.0 2Q03 28.3 57.0 is not indicative of future crude oil pricing. Instead, our view to 3Q03 34.0 60.0 future pricing has been shaped through conversations with 4Q03 29.0 56.0 1Q04 30.2 56.0 polystyrene producers. In general, producers have been selling 2Q04 31.2 62.0 polystyrene at low profitability levels, which does not bode well 3Q04 35.3 68.0 4Q04 38.3 74.0 for price decreases should input costs decrease. Polystyrene 1Q05 43.9 82.0 pricing is being driven by styrene, which is made up of benzene 2Q05 48.3 81.5 3Q05 49.9 79.0 and ethylene (see Figure 7). While the price of benzene has been 4Q05 53.1 83.0 coming down, due to high inventory levels in Europe and Asia, Correlation: 0.95 * Polystyrene pricing reflects the forward period. ethylene pricing has been moving up, a result of low inventory Source: MTR analysis. levels caused by production outages due to the hurricanes. Given our feedback, our projections for polystyrene incorporate flat pricing going forward at 94 cents per pound through fiscal 2007. Contrary to this view, CMAI projects that polystyrene pricing will decrease due to oversupply in Asia. Hurricane Rita. Hurricane Rita caused significant supply channel and production disruptions to chemical facilities located on the U.S. Gulf Coast, which produce styrene. In many cases, producers such as Dow Chemical, BASF and Nova Chemical were forced to declare force majeure, a contractual provision that allows producers to depart from the terms of a contract due to events that are neither foreseeable nor controllable. Styrene monomer production, in particular, was sharply reduced due to the lack of ethylene feedstock. Polyvinyl Chloride Polyvinyl chloride, or “PVC” as it is more commonly known, is a widely used plastic found in products ranging from clothing to piping and plumbing fixtures to garden hose. Its presence is so pervasive in the building industry through its use in pipe, conduit, frames and siding, that its 11

- 12. demand cycles with construction trends. The American Plastics Council estimates that rigid pipe and tubing account for half of all domestic PVC sales in the United States and Canada, while other construction-related uses account for almost 22%. Tekni-Plex makes use of PVC in its medical packaging business and throughout its Tubing Products and Other (compounding) reported segments. PVC is produced from its monomer, vinyl chloride, which is dependent upon natural gas, chlorine and ethylene (see Figure 7). During the manufacturing process (as with garden hose), PVC is often mixed with plasticizers, stabilizers and pigments to produce a variety of physical qualities. Pricing. While Tekni-Plex uses recycled PVC in the production of Figure 10 garden hose, our analysis utilizes the market pricing of prime PVC FEEDSTOCK (also known as virgin PVC) as a proxy for recycled PVC, due to CORRELATION Fiscal Lt.Swt.Crude PVC * the difficulty associated with sourcing pricing information on the Period ($/barrel) (cts/lb) recycled derivative (prime and recycled PVC are highly 1Q03 28.3 36.0 2Q03 28.3 38.0 correlated). Pricing on prime PVC has increased 61.5% since the 3Q03 34.0 43.0 first quarter of fiscal 2003, moving from 39 cents per pound to 63 4Q03 29.0 39.7 1Q04 30.2 41.0 cents per pound in the first quarter of fiscal 2006. The extremely 2Q04 31.2 43.0 high correlation between prime PVC and light sweet crude oil is 3Q04 35.3 47.7 4Q04 38.3 49.0 delineated in Figure 10 and graphed in Figure 11. 1Q05 43.9 51.5 2Q05 48.3 55.5 3Q05 49.9 57.5 As with polystyrene, PVC pricing is not only dependent on 4Q05 53.1 63.0 petrochemical pricing but also on the supply and demand dynamic Correlation: 0.98 of its chemical and monomer feeds. Dow Chemical will soon be * PVC pricing reflects the forward period. Source: MTR analysis. taking vinyl chloride monomer capacity out of the marketplace, accounting for a 10% reduction in domestic production capacity. It has been speculated that PVC pricing has risen so high that current pricing may spur the use of substitutes such as concrete and ductile iron for rigid pipe in the construction industry. While there appears to be a number of opposing forces on pricing, we have based our projections on our conversations with PVC producers which predict some pricing relief over the coming year. Forecasted PVC pricing is an Figure 11 extremely important driver in our model for Tekni-Plex’s PRIME PVC vs. LIGHT SWEET CRUDE OIL PRICING Tubing Products segment 75 70 profitability. Tekni’s near- Lt. Swt. Crude Oil ($/barrel) 70 65 60 PVC (cents/lb) term future is highly dependent 65 55 60 on its success in recovering raw 55 50 45 material price increases. This 50 40 45 will, of course, be made all the 40 35 30 more unlikely should PVC 35 25 pricing continue to rise. We 03 03 03 03 04 04 04 04 05 05 05 05 2Q 6 3Q E 4Q E 1Q E 2Q E E 0 06 06 06 07 07 1Q 2Q 3Q 4Q 1Q 2Q 3Q 4Q 1Q 2Q 3Q 4Q 1Q have forecast PVC pricing to increase to 72 cents per pound Prime PVC Lt. Sweet Crude Oil in the second quarter of fiscal * X-axis reflects Company's fiscal calendar. 2006, remain flat into the Source: Plastics News and NYMEX. third quarter of fiscal 2006, and thereafter decline by 4 cents per pound each quarter to 61 cents per pound in the second quarter of fiscal 2007. 12

- 13. Hurricane Rita. According to Chemical Market Resources, over 60% of PVC production is based in the U.S. Gulf Coast region. PVC (as well as polystyrene) is produced with raw materials that are transported by barges to the ports of New Orleans, LA and Gulfport, MS. According to CMAI, as of September 29, 2005, North American PVC capacity had been reduced by 20% due to Hurricane Rita, but as of the writing of this report, normal production levels had been resumed. The problems that will be encountered with PVC pricing in the near-term have more to do with the damage Rita caused to natural gas and ethylene production facilities, rather than to PVC plants. With limited supply of natural gas and ethylene, PVC producers were unable to manufacture PVC. This resulted in inventory being driven to low levels across the supply chain and through to the end-user markets. While inventories are usually built up during the calendar first quarter, we believe they will, at best, be maintained in the first quarter of fiscal 2006. This dynamic may serve to support PVC pricing at current levels. China. China will be a key determinant in the future worldwide supply and demand equation for PVC. Fueled by infrastructure projects, as well as the export of fabricated goods, Chinese annual PVC demand is expected to exceed that of the United States in 2005 at 16.5 billion pounds. By 2010, China PVC demand is projected to grow to more than 22 billion pounds. With an outlook to self-sufficiency, China is aggressively adding PVC production capacity. In 2005, CMAI forecasted an increase of 9.6% for Chinese demand for PVC, with capacity projected to increase over 35% during the same period and 17% in 2006. Capacity increases in China are expected to reduce worldwide PVC price levels. CMAI forecasts that by 2010, China PVC imports will decline to 1.0 million metric tons, down 47% from 2000. Increased China PVC production will ultimately lead to greater recycled PVC supply. CORPORATE STRUCTURE Figure 12 TEKNI-PLEX MANAGEMENT LLC Controlled by Dr. F. Patrick Smith Sole Managing Member of Tekni-Plex Partners and MST/TP Partners TEKNI-PLEX PARTNERS LLC MST/TP PARTNERS LLC Owns 94% of Tekni-Plex Common Stock Owns 6% of Tekni-Plex Common Stock (91.7% fully diluted) (5.8% fully diluted) TEKNI-PLEX, INC. Revolving Credit Facility 10.875% Senior Secured Notes 8.75% Senior Secured Notes 12.75% Senior Sub. Notes DOMESTIC SUBSIDIARIES FOREIGN SUBSIDIARIES Guarantors of: Revolving Credit Facility PurePlast Acquisition Limited (Nova Scotia) 10.875% Senior Secured Notes PurePlast Inc. (Ontario) 8.75% Senior Secured Notes Tekni-Plex Europe, N.V. (Belgium) 12.75% Senior Sub. Notes Action Technology Italia S.p.A (Italy) Colorite Europe, Ltd. (Northern Ireland) PureTec Corporation Colorite Plastics Canada Ltd. (Ontario) Plastic Specialties and Technologies, Inc. Tekni-Plex Holdings (Canada) Ltd. (Nova Scotia) Plastic Specialties and Technologies Investments, Inc. Tekni-Plex Argentina, S.A. (Argentina) Burlington Resins, Inc. Tekni-Plex, Inc. (Singapore) Natvar Holdings, Inc. Tri-Seal Holdings, Inc. TP-Elm Acquisition Subsidiary, Inc. TPI Acquisition Subsidiary, Inc. Source: Company reports. 13

- 14. CAPITAL STRUCTURE Each of Tekni-Plex’s debt instruments has been borrowed by or issued at the parent, Tekni-Plex, Inc. Tekni-Plex, Inc. is operational, comprising five plant locations, a result of the 1997 merger with Dolco Packaging Corp. (26.0% of consolidated net sales). Additionally, Tekni-Plex, Inc.’s debt is guaranteed by all domestic subsidiaries. Revolving Credit Facility On June 10, 2005, Tekni-Plex entered into a new four-year $65 million asset-based credit facility with Citicorp USA. The new facility was part of a refinancing of the Company’s old $100 million revolver and $70 million term loan. As of September 30, 2005, there were no outstanding borrowings under the facility. Net of $5 million of LC’s, revolver availability was $60 million. Tekni-Plex, Inc. is the borrower of the revolving credit facility, and each of its domestic subsidiaries is a guarantor of the facility. The credit facility is secured on a first priority basis by the accounts receivable, inventory, general intangibles and certain other assets of the borrower and the guarantors (“ABL Facility Priority Collateral”) (see Figure 13). Additionally, it contains a letter of credit sub-limit of $25 million and a swing loan sub-limit of $15 million. Outstanding borrowings are Figure 13 charged an interest rate equal TEKNI-PLEX Debt Collateral to the sum of a Base Rate, which is approximately 0.5% ABL FACILITY PRIORITY COLLATERAL NOTE PRIORITY COLLATERAL plus the Federal Funds Rate, Accounts Receivable Inventory Instruments, Accounts PP&E and an applicable margin General Intangibles Certain Real Property Certain Other Assets Equity ranging from 1.25% to 1.75%, (Domestic subs, 65% Foreign subs.) depending upon the Monthly Available Credit. The facility’s Borrowing Base is REVOLVING CREDIT FACILITY calculated as the sum of 1) Amount: $ 65 million 85% of Eligible Receivables; 2) the lesser of (a) 85% of the orderly liquidation value of 10.875% SENIOR SECURED NOTES Eligible Finished Goods and Amount: $ 150 million (b) 75% of Eligible Finished Goods; and 3) the lesser of (a) 85% of the orderly liquidation 8.75% SENIOR SECURED NOTES Amount: $ 275 million value of Eligible Raw Materials, and (b) 75% of Source: Company reports. Eligible Raw Materials, less an Eligibility Reserve. Asset sales are governed under a negative covenant provision in the credit agreement. To the extent that an asset sale includes credit facility collateral, the sale must include substantially all of the assets constituting the unit of operation, and 1) net cash proceeds shall neither exceed $25 million in any fiscal year nor $50 million during the term of the Agreement, 2) consideration must be at least 75% cash and 3) net cash proceeds must be applied to repay borrowings under the facility. The credit agreement also limits capital expenditures to $55 million, $40 million, $35 million and $35 million for the fiscal years 2006 through 2009, respectively; the covenant does incorporate a spending rollover provision. 14

- 15. 10.875% 1st Lien Senior Secured Notes Tekni-Plex issued $150 million of 1st Lien Notes on June 10, 2005 as part of the refinancing of its old senior secured credit facility. The Notes bear interest at an annual rate of 10.875%, payable semiannually on February 15 and August 15, and are scheduled to mature on August 15, 2012. The Company will make its first coupon payment on February 15, 2006. The 1st Lien Notes are issued by Tekni-Plex, Inc. and are guaranteed by all domestic subsidiaries. The obligations are secured on a first priority basis by all instruments and accounts, PP&E and real property of both Tekni-Plex, Inc. and the guarantors, as well as the equity of all the domestic subsidiaries and 65% of the capital stock of all the foreign subsidiaries (“Note Priority Collateral”) (see Figure 13). The Notes are also secured on a second priority basis by the ABL Facility Priority Collateral and are thus effectively subordinated to the Credit Facility. The 1st Lien Notes indenture allows the Company to incur indebtedness such that, prior to June 10, 2006, the calculated pro forma Fixed Charge Coverage Ratio for the most recent four full fiscal quarters is not greater than 2.0x; after June 10, 2006, ratio compliance is achieved at 2.25x. The Note indenture defines the Fixed Charge Coverage Ratio as the ratio of the Consolidated Cash Flow to Fixed Charges for the prior four-quarter period. Consolidated Cash Flow is defined as Consolidated Net Income plus, to the extent deducted, extraordinary losses, taxes, Fixed Charges, depreciation and amortization, non-cash items that do not relate to accruals or reserves. Fixed Charges are defined as consolidated interest expense plus preferred stock dividends adjusted for taxes. Indebtedness under the credit facility is limited to $125 million less the aggregate amount of asset sale net proceeds applied by the Company to permanently repay term debt or revolving debt which leads to a corresponding commitment reduction. Permitted debt also includes a basket for the incurrence of additional unsecured indebtedness in an amount, at any time outstanding, of $40 million, which has already been used. As specified in the 1st Lien Note indenture, net proceeds from an asset sale may be applied, within 365 days, to the following: 1) to the extent the asset sale involves ABL Facility Priority Capital, to reduce commitments under the revolving credit facility, 2) to acquire the assets or capital stock of a Permitted Business, 3) to make capital expenditures, and 4) to acquire useful assets. Any proceeds in excess of $15 million not applied to the aforementioned will be used to purchase the 1st Lien Notes and other indebtedness that is secured equally and ratably with the Notes. The Notes are callable on or after August 15, 2009 at $105.438, August 15, 2010 at $102.719, and August 15, 2011 and thereafter at $100. The Notes carry a change of control put at 101%. 8.75% 2nd Lien Senior Secured Notes The Company issued $275 million of 2nd Lien Senior Secured Notes on November 21, 2003, the proceeds of which were used to pay down the term loan of a previous credit facility. The Notes bear interest at an annual rate of 8.75%, payable semiannually on May 15 and November 15, and are scheduled to mature on November 15, 2013. The 2nd Lien Notes were issued by Tekni-Plex, Inc. and are guaranteed by all domestic subsidiaries. The Notes are secured by liens junior to that of the 1st Lien Notes on the ABL Facility Priority Collateral and the Note Priority Collateral and are effectively subordinated to the 1st Lien Notes (see Figure 13). The 2nd Lien Notes’ indenture contains a number of 15

- 16. provisions that govern additional indebtedness. The Company may incur indebtedness such that the calculated pro forma Fixed Charge Coverage Ratio for the most recent four full fiscal quarters is not greater than 2.25x. The Note indenture defines the Fixed Charge Coverage Ratio using similar language to that found in the 1st Lien Note indenture. Indebtedness under the credit facility is limited to $275 million (as compared with $125 million under the 1st Lien Note indenture) less the aggregate amount of asset sale net proceeds applied by the Company to permanently repay term debt or revolving debt which leads to a corresponding commitment reduction. Permitted debt also includes a basket for the incurrence of additional unsecured indebtedness in an amount, at any time outstanding, of $40 million, which has already been used. The language governing the net proceeds from an asset sale is similar to that in the 1st Lien Note indenture. Any proceeds in excess of $15 million not applied to the aforementioned will be used to purchase the 2nd Lien Notes and other indebtedness that is secured equally and ratably with the Notes. The Notes are callable on or after November 15, 2008 at $104.375, November 15, 2009 at $102.917, November 15, 2010 at $101.458, and November 15, 2011 and thereafter at $100. The Notes carry a change of control put at 101%. 12.75% Senior Subordinated Notes In June 2000 and May 2002, the Company issued $275 million and $40 million of 12.75% Senior Subordinated Notes, respectively. The proceeds from the initial issuance were part of a recapitalization of Tekni-Plex, Inc. and that of the second issue were used to repay borrowings under the old revolving credit facility. The Notes bear interest at an annual rate of 12.75%, payable semiannually on June 15 and December 15, and are scheduled to mature on June 15, 2010. The Subordinated Notes are issued by Tekni-Plex, Inc. and are guaranteed by all domestic subsidiaries on a subordinated basis to the guarantees of the Senior Debt. The Notes are contractually subordinated to all Senior Debt and thus rank junior in right of payment to the Credit Facility, 1st Lien Notes and 2nd Lien Notes. They are also structurally subordinated to indebtedness and other liabilities of all the non-guarantor foreign subsidiaries. The Subordinated Notes are callable on or after June 15, 2005 at $106.375, June 15, 2006 at $104.25, June 15, 2007 at $102.125, and June 15, 2008 and thereafter at $100. The Notes carry a change of control put at 101%. Additional Indebtedness. Effective June 10, 2005, an Figure 14 amendment to the Subordinated Note indenture, which had TEKNI-PLEX been approved through a consent solicitation, allowed Tekni- Additional Indebtedness Plex to borrow up to an incremental $90 million at any one Equity Received Post-4/15/05 $ 37.2 time outstanding, in a ratio of 1.5:1.0 for every dollar of equity Available Additional Debt (1.5x) 55.8 New Debt Issued: received after April 1, 2005. Having received an equity Credit Facility 65.0 infusion in the amount of $37.2 million in the form of Series A st 1 Lien Notes 150.0 Subtotal 215.0 Preferred Stock (see following page), Tekni-Plex was able to Less: Old Debt Refinanced: issue an additional $55.8 million of debt (see Figure 14). At Revolver 100.0 Term Loan 70.7 current equity infusion levels, we estimate that the Subtotal 170.7 Company has provided for an additional $11.5 million of Additional Debt Used 44.3 Calculated Additional Debt, net $ 11.5 debt. Along with a basket provision in the Note indentures LC Basket Provision 5.0 to which the Company can allocate its letters of credit, we Total Available Additional Debt $ 16.5 calculate that Tekni can issue a total of $16.5 million of Source: Company reports and MTR analysis. 16

- 17. additional debt. Additional debt beyond the $16.5 million will require additional equity; the Subordinated Note supplemental indenture provides for additional debt of $34.2 million (totaling $90 million), which would require an additional equity investment of $22.8 million. This is more restrictive than the language in the Senior Secured Notes’ indentures, which will allow an additional $60 million of Credit Facility debt. Thirty million of the post-4/15/05 $37.2 million Series A Preferred investment was made by Weston Presidio. It is unclear who will invest additional equity in future financing rounds, given Weston’s unrequited desire to reduce its Series A exposure from $30 million to $15 million and its co-investors’ disinterest in participating in the prior investment round. Series A Preferred Stock As part of the Subordinated Note consent solicitation requiring the investment of additional equity, Tekni authorized 82,500 shares of Series A Preferred Stock through an Amended and Restated Certificate of Incorporation dated May 13, 2005. To-date, a total of $37.2 million of Series A Preferred Stock has been purchased, comprised of $30 million of equity contributed by Weston Presidio, $1.8 million by Dr. F. Patrick Smith, $5 million from Forrest Binkley & Brown Capital Partners, $230,527 by Michael Cronin, managing partner of Weston Presidio, and $192,249 by other existing investors. Missing in the investor roster is a number of large institutional investors that had previously co-invested alongside Weston Presidio in prior investment rounds. Accreting at an estimated 16% per annum, there was $64.0 million Series A Preferred outstanding as of September 30, 2005. The Series A Preferred Stock is to be redeemed at three times the purchase price upon the occurrence of a sale of the Company or its subsidiaries, whether by merger, asset sale, change in equity control, or liquidation; in addition, the Preferred Stock is to be redeemed at three times the purchase price upon the earlier of i) of February 15, 2014 and ii) to the extent such redemption is permitted under the Company’s new asset-based credit facility, the payment in full of the Company’s Senior Subordinated Notes and existing Senior Secured Notes. Upon a Triggering Event, the Preferred Stock will be entitled to receive cumulative dividends at a rate of 12% per annum, compounded quarterly. A Triggering Event is defined, in part, as the failure of the Company to redeem Series A Preferred shares, the failure to comply with covenants in the Series A Stock Purchase Agreement, the failure to service Company debt, a Chapter 11 filing, and the date April 30, 2007. Upon a Triggering Event, the Series A Preferred Stockholders assume control of Figure 15 TEKNI-PLEX the Company’s board of directors. Leverage As of September 30, 2005 Leverage / Liquidity Amount Leverage As of the first quarter of fiscal 2006 ended September ($ millions) Thru Revolving Credit Facility $ - 0.0x 30, 2005, Tekni had $693.4 million of net debt. 10.875% Senior Secured Notes 146.7 2.2x Using an LTM adjusted EBITDA of $67.8 million, 8.75% Senior Secured Notes 268.8 6.1x the Company’s net interest coverage and net leverage 12.75% Senior Sub. Notes 313.5 10.8x Foreign Term Loan 4.8 10.8x ratios were 0.71x and 10.2x, respectively, for the period (see Figure 15). At the end of the quarter, Total Debt $ 733.8 10.8x there were no borrowings under the $65 million Series A Preferred Stock 64.0 11.8x revolving credit facility. Net of approximately $5.0 Total Obligations $ 797.8 11.8x million of letters of credit, facility availability was LTM Adjusted EBITDA $ 67.8 $60 million. Together with cash on hand in the Source: Company reports and MTR analysis. 17

- 18. amount of $40.4 million, total liquidity as of September 30, 2005 was $100.4 million. MANAGEMENT / OWNERSHIP / CONTROL It has been estimated that, prior to the issuance of the Series A Preferred Stock, Weston Presidio and its co-investors had approximately $300 million invested in Tekni-Plex, translating into approximately a 60% ownership stake in Tekni-Plex’s equity; Dr. F. Patrick Smith is estimated to own more than 20% of the Company’s equity. Since the issuance of the Series A Preferred Stock and the amendment of the Certificate of Incorporation, day-to-day control has effectively shifted to Weston Presidio. As long as shares of the Preferred Stock are issued and outstanding, the Company is not permitted, without the approval of the Series A Preferred stockholders, to engage in the following: 1) consummate the sale of the Company or any significant subsidiary; 2) issue any securities other than 45.752 shares of common stock and certain refinancing securities; 3) liquidate or dissolve the Company or any subsidiary; 4) declare or pay any dividend, or redeem any securities other than Series A Preferred Stock; 5) change the number of Company directors; 6) incur any indebtedness that would prohibit the redemption of the Preferred Stock; and 7) hire, terminate or modify the compensation of the CEO, CFO and COO. As stated previously, upon a Triggering Event, the Series A Preferred Stockholders assume control of the Company’s board of directors. RELATIVE VALUE While Tekni-Plex faces competition across each of its product categories, the fragmented nature of the flexible packaging industry allows a relatively small company such as Tekni to identify and dominate niches within its markets. While Tekni’s direct competitors are few in number, this section will briefly address direct and indirect public competitors that share similar industry dynamics. As shown in Figure 16, the range of EV/EBITDA multiples, from 7.3x to 8.3x, is narrow. Within a historical context, these multiples compare favorably to a twenty-year industry average of 7.5x. There is a significant valuation premium attributed to size in the packaging industry and as such when applied, the multiples delineated need to be adjusted downward to account for Tekni’s relatively lower product line volume and revenue base. Figure 16 Specialty Packaging - Public Comparables Financials as of September 30, 2005 Stock Price as of November 18, 2005 (In Millions of Dollars) LTM LTM EBITDA Enterprise EV / EV / Net Debt / Company Ticker Specialty Sales EBITDA Margin Net Debt Value EBITDA Sales EBITDA Tekni-Plex TEKNI Flexible packaging $ 714.8 $ 67.8 9.5% $ 693.3 NA NA NA 10.2x Pactiv PTR Flexible packaging 3,516.0 544.0 15.5% 1,112.0 3,955.0 7.3x 1.12x 2.0x AptarGroup ATR Dispensing pumps 1,384.5 255.4 18.4% 65.3 1,939.0 7.6x 1.40x 0.3x Bemis BMS Flexible packaging 3,307.5 433.5 13.1% 688.5 3,518.0 8.1x 1.06x 1.6x Sealed Air SEE Protective packaging 4,026.5 708.5 17.6% 1,626.0 5,850.0 8.3x 1.45x 2.3x Sonoco Products SON Packaging 3,458.7 455.9 13.2% 756.9 3,552.0 7.8x 1.03x 1.7x Source: Company Reports and MTR analysis. Pactiv (PTV). Pactiv is a global supplier of specialty packaging and consumer products. Operating through three segments, Consumer Products, Foodservice/Food Packaging, and Protective and Flexible Packaging, the company produces molded-fiber egg cartons, foam trays 18

- 19. for meat, plastic cutlery, take-out service containers, plastic bags under names such as Hefty, Baggies, and EZ Foil, as well as padded mailers and medical packaging. LTM sales for the period ending September 30, 2005 were $3.5 billion with LTM EBITDA of $544 million, or 15.5% of sales. The company’s net leverage ratio was 2.04x. AptarGroup (ATR). AptarGroup is a leading global supplier of dispensing pumps for the personal care, pharmaceutical, household and food/beverage markets. The company’s subsidiaries, which include Emsar, Pfeiffer, SeaquistPerfect Dispensers, and Valois, produce pumps, closures and aerosol valves. LTM sales for the period ending September 30, 2005 were $1.4 billion with LTM EBITDA of $255 million, or 18.4% of sales. Its net leverage ratio was 0.26x. Bemis (BMS). Bemis operates through two segments: the Flexible Packaging segment and the Pressure Sensitive Materials segment. Accounting for 79% of fiscal 2004 sales, the Flexible Packaging segment manufactures a broad range of consumer and industrial packaging, including flexible film structures and laminates, sealing tapes and paper bags. These products are sold to the food and beverage industry, agribusiness, minerals, and medical device packaging. The Pressure Sensitive Materials segment manufactures pressure sensitive materials that are sold into label, graphic and technical markets. For the period ending September 30, 2005, LTM sales were $3.3 billion, and LTM EBITDA was $434 million, or 13.1% of sales. The net leverage ratio is calculated at 1.59x. Sealed Air (SEE). Sealed Air’s Food Packaging segment primarily produces bags, films and laminates which customers use to package a broad range of perishable foods. In conjunction with its materials offerings, Sealed Air also sells food-packaging equipment. Its Protective and Specialty Packaging segment produces Bubble Wrap, Instapak foam, Jiffy envelopes and Rapid Fill inflatable packaging systems. LTM sales for the period ending September 30, 2005 were $4.0 billion, while LTM EBITDA was $709 million, or 17.6% of sales. The company’s net leverage ratio was 2.29x. Sonoco Products (SON). Sonoco Products is one of the world’s largest manufacturers of industrial and consumer packaging products. Through its Engineered Carriers and Paper segment, the company makes tubes, cores and recycled paperboard for the construction, textile, beverage and paper manufacturing industries. Its Consumer Packaging segment makes ends and closures for containers, rigid packaging for the food and non-food markets, as well as printed flexible packaging. For the period ending September 25, 2005, LTM sales were $3.5 billion with EBITDA of $456 million, or 13.2% of sales. Its net leverage ratio was 1.66x. RECENT FINANCIAL RESULTS Packaging Over the past two years, Tekni’s Packaging segment has come under margin pressure due to the rising cost of polystyrene (see Figure 8). Polystyrene has increased 12% during the last four fiscal quarters and 64% over the past eight quarters to an estimated 92 cents per pound in the second fiscal quarter of 2006. In response, Tekni has successfully passed through the dollar increase in rising raw material costs, resulting in lower gross margin. Gross profit for fiscal 2004 and 2005 was $80.1 million and $83.1 million, respectively, while gross margin declined from 26.2% to 23.8% over the same period (see Figure 17). Quarterly adjusted SG&A expense rose substantially over the two-year period, increasing from $6.6 million in the first quarter of fiscal 19

- 20. 2004 to $9.7 million in the fourth quarter of fiscal 2005, accounting for the decrease in adjusted EBITDA from $66.4 million in fiscal 2004 to $64.2 million in fiscal 2005. Packaging segment net sales grew 4.0% year-over-year to $85.1 million in the first quarter of fiscal 2006, primarily due to the pass-through of higher selling prices. Gross profit was basically flat at $20.7 million, as compared with the prior year’s quarter, reflecting the dollar-for-dollar pass-throughs. SG&A expense decreased $1.8 million from the prior quarter ended July 1, 2005, primarily due to lower executive compensation. Adjusted EBITDA for the first quarter of fiscal 2006 was flat at $16.3 million, compared with $16.4 million in the first quarter of fiscal 2005. Tubing Products Tekni’s Tubing Products segment has been adversely affected by the performance of the garden hose business (86.5% of Tubing Products net sales). Rising PVC prices, combined with management’s previous unwillingness to pass-through price increases, has greatly hurt financial results. Since September 2003, Prime PVC has increased from 39 cents per pound to 72 cents per pound, or 84.6%, while Tekni’s pricing of garden hose has increased an estimated 8.2% (see Figure 11). This has resulted in a gross profit decline from $23.3 million in fiscal 2004 to $10.0 million in fiscal 2005 (see Figure 17). Adjusted EBITDA has decreased in concert with gross profit, declining from $18.6 million in fiscal 2004 to $5.7 million in fiscal 2005. Tubing Product segment net sales increased 39.3% to $43.2 million in the first quarter of 2006 from $31.0 million in the first quarter of 2005. The increase was driven by a weather-related shift in timing, moving volumes from the fourth quarter of fiscal 2005 to the first quarter of fiscal 2006. Gross profit declined to negative $0.5 million in the quarter from $6.7 million in the prior year’s quarter as a result of Tekni’s unwillingness to raise prices sufficiently to compensate for significantly higher raw material costs. Adjusted EBITDA for the quarter ended September 30, 2005 was negative $1.3 million, down $6.8 million from the prior year’s quarter. Other Tekni’s Other segment, which comprises the Company’s materials compounding businesses, has improved slightly over the past two years. With gross profit increasing from $4.5 million in fiscal 2004 to $5.2 million in fiscal 2005, it is likely that Tekni has grown unit volume. Adjusted EBITDA increased 16% over the prior year to $5.8 million in fiscal 2005. Other segment net sales grew 12.4% year-over-year to $34.5 million in the quarter. Gross margins increased 50bps to 6.7%, as higher sales volumes provided greater absorption of the operation’s fixed costs. Adjusted EBITDA improved to $2.8 million, or 8.0% of net sales, for the quarter ended September 30, 2005, up from $2.0 million, or 6.4% of net sales, in the prior year’s quarter. 20