Construction and Architecture Magazine 13 sept oct 2011

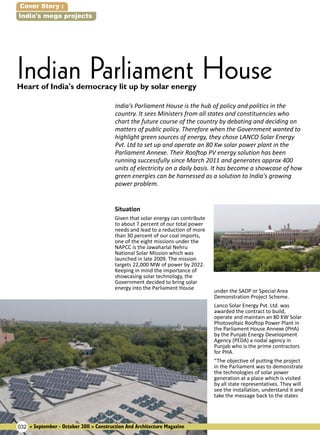

- 1. Cover Story : India's mega projects Indian Parliament House Heart of India's democracy lit up by solar energy India's Parliament House is the hub of policy and politics in the country. It sees Ministers from all states and constituencies who chart the future course of the country by debating and deciding on matters of public policy. Therefore when the Government wanted to highlight green sources of energy, they chose LANCO Solar Energy Pvt. Ltd to set up and operate an 80 Kw solar power plant in the Parliament Annexe. Their Rooftop PV energy solution has been running successfully since March 2011 and generates approx 400 units of electricity on a daily basis. It has become a showcase of how green energies can be harnessed as a solution to India's growing power problem. Situation Given that solar energy can contribute to about 7 percent of our total power needs and lead to a reduction of more than 30 percent of our coal imports, one of the eight missions under the NAPCC is the Jawaharlal Nehru National Solar Mission which was launched in late 2009. The mission targets 22,000 MW of power by 2022. Keeping in mind the importance of showcasing solar technology, the Government decided to bring solar energy into the Parliament House 032 » September - October 2011 » Construction And Architecture Magazine under the SADP or Special Area Demonstration Project Scheme. Lanco Solar Energy Pvt. Ltd. was awarded the contract to build, operate and maintain an 80 KW Solar Photovoltaic Rooftop Power Plant in the Parliament House Annexe (PHA) by the Punjab Energy Development Agency (PEDA) a nodal agency in Punjab who is the prime contractors for PHA. “The objective of putting the project in the Parliament was to demonstrate the technologies of solar power generation at a place which is visited by all state representatives. They will see the installation, understand it and take the message back to the states

- 2. Cover Story : Cover Story : India's mega projects India's mega projects for replication of similar models,” says senior spokesperson of PEDA. The Parliament House Annexe is a part of the Parliament House Estate, which has been operational since 1927 and is home to 790 members. It houses many services for the Parliamentarians including a post office, a State Bank of India branch, telephone exchange and a fully equipped Medical Centre and secretariats of both houses. Being a highly sensitive installation which is subject to strict security precautions all round the year, there were added need for strict safety procedures and the need to meet deadlines as well. Advanced systems such as the Max Power Point Tracking or MPPT system can harvest maximum possible energy from the sun and supply it to the grid. The energy produced is measured using the Data Monitoring and Control System which measures in real time the amount of energy being produced by the solar plant.The solar plant has now been up and running since March 2011. Benefits Solution 400 units of electricity per day are generated by 288 numbers of 290 WP solar panels placed on the rooftop of the Annexe. They are combined with power supply from conventional sources with help of an interactive grid power conditioning unit.They are connected in 24 strings and each string consists of 12 modules. These modules rest on 48 steel structures which are specially treated with anti corrosive zinc phosphate and finished with polyurethane silver paint to ensure durability since they are exposed to extreme climate conditions. The modules are south facing fixed at an angle of 26 degrees to best absorb the solar isolation. The energy generated by these modules is then fed to the low tension grid through the state-of-the-art high efficiency power conditioning unit installed in the control room. The installation of the solar plant in the Parliament House Estate meets many criteria considering its unique location and thus serves many purposes. Visibility to leaders of social change This prestigious rooftop project is very visible to policy makers from all over the country who can replicate this model at the state and local levels. Encourages generation of solar energy on roof top It serves as a showcase of how green energy can be generated and used for captive consumption in public and private buildings. Merges in with its ambient surroundings The entire estate is well known and recognized for its aesthetic elements. The style of architecture is modern, functional and dignified. The solar plant blends in with the aesthetics of the area. Rooftop installations attract attention Being highly visible in the public eye, the rooftop PV plant will attract considerable attention and contribute to increasing awareness of conservation of power and environmental responsibility. Lanco also sees a great future in the rooftop solar market as it provides consumers the opportunity to generate energy wherever they are. According to V Saibaba, CEO, LANCO Solar Energy Pvt. Ltd., “The rooftop projects are a small capacity power plant sitting on the roof of a house which is going to be the reality going forward into the future.” Key Business benefits Substantial reduction in upfront investment - pay per user per month Rapid start - templatized Access to global best practices No need to own SAP manpower for ongoing support De-risking Level playing field for SMEs Segment Best suited for Jv’s (Limited life span) 034 » September - October 2011 » Construction And Architecture Magazine GTP's Howrah - Delhi Grand Chord railway line crosses the river Barakar in Asansol – Dhanbad section at a distance of at 230 km from Howrah in between Barakar and Kumardhubi railway stations. Construction of Barakar Railway Bridge H owrah - Delhi Grand Chord railway line crosses the river Barakar in Asansol – Dhanbad section at a distance of at 230 km from Howrah in between Barakar and Kumardhubi railway stations. The existing steel girder bridge (No. 18) carrying the UP railway track, being very old required replacement. The new bridge is located on a slightly diverted alignment from old bridge as the very busy rail route has to run during construction. The Chief Administrative Officer (Construction), Eastern Railway awarded the project of Construction of New Bridge No. 18 to GPT Infraprojects Limited. The project consisted of construction of 574 m long bridge with open web steel girder superstructure on RDSO design, design and construction of foundation, substructure, and embankment for linking the bridge on diverted alignment, and connecting it with the existing track at both sides. The existing steel girder bridge (No. 18) carrying the UP railway track, being very old required replacement. The new bridge is located on a slightly diverted alignment from old bridge as the very busy rail route has to run during construction. 036 » September - October 2011 » Construction And Architecture Magazine

- 3. Cover Story : Cover Story : India's mega projects India's mega projects stage. On completion of erection of a span riveting work of the joints is done. Link members are then erected at the front end at first span for taking up the second span. The process is continued till 4 spans of 30.5m are erected. Methodology of Construction: Pile Foundations: In working season the river remains almost dry except narrow water channel towards one bank. In most of the foundation, installation of piles was carried out from dry river bed. Island with surrounding coffer dam was adopted for a few of the foundations location. Rock was found at either at shallow depth or exposed at surface. Required minimum embedment of pile inside rock with RQD greater than 50% was 4 x pile diameter, i.e. 4.8M to 6M. Hydraulic Rotary Drilling Machine (MAIT HR–180 and Casagrande B170) were used for installation of piles. These machines are capable of developing large torque (200 TM) at moderately high speed (10.6 rpm). In addition a number of conventional DMC boring rigs were also deployed. Average time required by Drilling rig and Conventional rig for a pile of 15 M depth in similar rocky strata was found to be 15 and 80 working hours respectively. Substructure: Multiple circular hollow piers, up to 27 m high, constructed using hydraulically operated slip-form system. The slip-form was assembled and started operating right from the pile cap level. The whole assembly of forms is suspended from a spider beam arrangement which in turn is supported on sleeve and jack rods passing through shaft concrete. Equally spaced hydraulic jacks connected through manifold to electrically operated hydraulic pump lifts the form work assembly and working platform at a slow and controlled speed. Rate of lifting is adjusted at about 10 cm per hour. 27 m high pier could be completed in 15 days by using slip-form system, which otherwise would require months together with conventional forms. Steel Superstructure – Fabrication: The steel girders used for the superstructure of Barakar bridge were 30.5m (100’) and 45.7m (150’) welded open web girders, with each span weighing 62 MT and 136 MT respectively. The drawings adopted were standard Railway span drawings prepared by Railway Designs and Standards Organization (RDSO). Field connections were done using 22mm diameter mild steel rivets conforming to IS-1148. The fifth span, being 45.7 m, is heavier than previous span and can not be counter balanced by the latter. Procedure followed here is Free Cantilever Method with a trestle support at mid span. Steel trestle is erected at centre of Span. Different set of link member is erected at end of fourth (30.5 m) span. Cantilever erection followed till structure is erected up to mid span and supported over the trestle. Link members are removed. Kentiledge is placed on rear end of fifth (45.7 m) span. Cantilever erection is continued to complete the span and the same gets supported on front pier. Fabrication of the spans was done in a fully equipped workshop established at site. The fabrication of welded girders was done as per Quality Assurance Plan (QAP) approved by RDSO, and followed the guidelines laid down under Indian Railways’ Specification IRS B1-2001. The workshop established at site consisted of all required equipments for proper workmanship, quality control and handling of components. Welding was done using Submerged Arc Welding (SAW) process wherever applicable, and quality of welds was subjected to 100% testing. In order to improve the life of the girders, the surface protection of the components was done by sandblasting the surface to SA 2.5, followed by aluminum spray metalizing of 150 microns with 99.5% pure aluminum. The metalizing was followed by application of 1st coat of etch primer (IS-5666), followed by 2 coats of zinc chromate primer conforming to IS-104. Thereafter 2 finishing coats of aluminum paint confirming to IS-2339 were applied. Steel Superstructure – Erection: Sixth and seventh spans are of same span length and weight as fifth span. Free cantilever process of erection as explained above is followed. However the set of link member and magnitude of counter weight are different. Check for adequacy of truss section for cantilever erection, as stress reversal is involved, was carried out. Some important precautions were taken during erection: Erection work was discontinued during high winds, as the operation in more than 50 kg/M2 wind force was not permissible. For erection of open web steel girder, Free Cantilever Method of erection was adopted. Erection proceeded from both ends of the bridge. Broad sequence followed is given below: Crane hook and cranes were left anchored with the girder during non-working hours and high winds. Erect Anchor span on embankment. Erect light weight Cantilever Erection Crane having 5 MT capacity, over top chord. Place kentiledge at rear end of the Span. Fix temporary vertical and link members along top chord. Erect components of a panel one by one. On completion of one panel move the crane forward and take up next panel. Components are joined by bolts and drifts at this Rotational movement of crane beyond 300 with bridge axis was restricted. 038 » September - October 2011 » Construction And Architecture Magazine Avoidable loads of bracings, cross girders, stringers were shed with till the span under erection is selfsupported on piers. Due to the span configuration of the bridge, four types of free cantilever erection methods had to be adopted, viz., (i) 30.5m span with 30.5m anchor span, (ii) 30.5m span with 45.7m anchor span, (iii) 45.7m span with 30.5m anchor span, and (iv) 45.7m span with 45.7m anchor span. Design of the cantilever scheme was prepared by M/s STUP Consultants, Kolkata on contractor’s behalf, and approved by Railway. Special Feature: Initially at the time of award, the bridge was meant for Modified Broad Gauge (MBG) loading as per prevailing railway loading standard. Subsequently, during execution Railway administration desired to adopt the upgraded 25 MT Axle Load Standard – 2008. Design and drawing for superstructure, was revised by Railway to suit higher loading standard. Foundation and substructure already at an advanced stage of construction, were checked for the higher loading standard, and found to be safe. Before the decision to adopt 25 MT Loading Standard 2008, structural steel for 8 spans (6 x 30.5 m and 2 x 45.7 m) were cut to size and fabrication proceeded as per drawings of MBG loading. Bridge Bearings for two spans was also ordered. Afterwards the steel components and bearings were utilized in other railway bridges under construction by GPTIL. Fabrication work for this bridge started afresh according to modified drawings of railways. 040 » September - October 2011 » Construction And Architecture Magazine

- 4. Cover Story : India's mega projects functionality at the required performance level also with large models, Tekla has designed a software architecture that combines available technologies with custom-built ones. The underlying foundation is Microsoft's .NET technology and its development tools. The .NET provides a vast amount of basic software development services and offers the highest available level of productivity for Tekla and its partners. .NET is also the industry standard in interconnecting desktop applications. Tekla's technology platform, Tekla Technology, provides the tools required for the model-based approach. The data model needs to work in an intelligent way and maintain full integrity at all times, and changes to it need to be visualized immediately. For example, when the profile of a beam in a structural model is modified, changes need to propagate to a number of connections and other parts in the model. Making sure that the model always behaves as needed without delay is what customers expect of Tekla. Keeping this promise allows our customers to reach the levels of productivity and quality they need to remain competitive in their own fields. Building Information Modeling (BIM) is the process of generating and managing building data during its life cycle. BIM involves representing a design as objects – vague and undefined, generic or product-specific, solid shapes or void-space oriented (like the shape of a room), that carry their geometry, relations and attributes. BIM design tools allow for extracting different views from a building model for drawing production and other uses. These different views are automatically consistent - in the sense that the objects are all of a consistent size, location, specification since each object instance is defined only once, just as in reality. Drawing consistency eliminates many errors. Typically it uses three-dimensional, real-time, dynamic building modeling software to increase productivity in building design and construction. The process produces the Building Information Model (also abbreviated BIM), which encompasses building geometry, spatial relationships, geographic information, and quantities and properties of building components. Pieces can carry Making sure that the model always behaves as needed without delay is what customers expect of Tekla. Keeping this promise allows our customers to reach the levels of productivity and quality they need to remain competitive in their own fields. attributes for selecting and ordering them automatically, providing cost estimates and well as material tracking and ordering.[2].This method of management is more practical and efficient. It eliminates many of the uncertainties found during the construction phase since they can be found during the design phase of the project and fixed so they do not occur during the actual construction phase. Also, any changes during construction will be automatically updated to BIM and those changes will be made in the model. Modern BIM design tools go further. They define objects parametrically. That is, the objects are defined as parameters and relations to other objects, so that if a related object changes, this one will also Managing the BIM Model guidelines "The production of a Building Information Model (BIM) for the construction of a project involves the use of an integrated multi-disciplinary performance model to encompass the building geometry, spatial relationships, geographic information, along with quantities and properties of the building components. The Virtual Design to Construction Project Manager (VDC - also known as VDCPM) is a professional in the field of project management and delivery. The VDC is retained by a design build team on the clients' behalf from the pre-design phase through certificate of occupancy in order to develop and to track the object oriented BIM against predicted and measured performance objectives. The VDC manages the project delivery through multi-disciplinary building information models that drive analysis, 044 » September - October 2011 » Construction And Architecture Magazine schedules, take-off, and logistics. The VDC is skilled in the use of BIM as a tool to manage and assess the technology, staff, and procedural needs of a project. In short the VDC is a contemporary project managing architect who is equipped to deal with the current evolution of project delivery. The VDC acts as a conduit to bridge time tested construction knowledge to digital analysis and representation. BIM as a Construction Management Tool The use of BIM goes beyond the design phase of the project and takes an important role during the construction phase of a project as well as the post construction phases and facility management. The entire purpose of BIM was to make the construction process more efficient and eliminate as many uncertainties as possible before starting the construction process. Participants in the building process are constantly challenged to deliver successful projects despite tight budgets, limited manpower, accelerated schedules, and limited or conflicting information. Innovations in BIM boast of capabilities to ease the pain of project delivery.The concept of Building Information Modeling is to build a building virtually prior to building it physically, in order to work out problems, and simulate and analyze potential impacts. Furthermore, along the project anticipation and ease of project delivery, the overall safety of the project will improve due to the elimination of uncertainty.The work site is safer because more items will be pre-assembled off site and trucked to the site keeping the on-site trades to a minimum. Waste will be minimized on-site and products will be delivered when needed and not stock piled on site. This will make a great impact in the way a construction project is managed and will also bring along a safer jobsite and more accurate construction with a more sophisticated design process which will allow sub contractors from every trade to input critical information into the software before the beginning of the actual construction.

- 5. Cover Story : Cover Story : India's mega projects India's mega projects In India, the brand Wärtsilä is synonymous with Captive Power for base load and peaking requirements. So far, around 250 power plants have been delivered to India with total output of around 3500 MW Our . plants offer high energy efficiency over the whole load range. Wärtsilä sets out to be the most valued business partner of all its customers. Wartsila introduces solutions for 24/7 power supply in Maharashtra with Smart Power Generation Wärtsilä India has announced that the power plant at Mangalore Chemicals & Fertilizers Ltd (MCF) in Karnataka has completed 25 years of successful and continuous operations. Wärtsilä India was formed in 1986 and a factory was setup at Khopoli near Mumbai in 1989. We have over 1100 employees spread over six sales and services offices. In India, the brand Wärtsilä is synonymous with Captive Power for base load and peaking requirements. So far, around 250 power plants have been delivered to India with total output of around 3500 MW. Our plants offer high energy efficiency over the whole load range. As importantly, our technologies are backed up by operations and management services that ensure efficiency and optimize lifecycle value for as long as you need. Over 55 power plants (including steam & wind turbines) with a total surpassing 1000 MW are under O&M in India. Wärtsilä's factory at Khopoli manufactures gear boxes, auxiliaries/pipe modules and, reconditions and upgrades engines, ship propellers and components. Also it integrates High speed DG sets for the marine sector requirement. The Wärtsilä Land and Sea Academy located at Khopoli provides training and competence management services to power plant owners and ship owners. Wärtsilä has a service workshop on both coasts: one at Khopoli, the other at Visakhapatnam and a dedicated dry docking facility located at Paradip port. Smart Power Generation: “Smart Power Generation” brings a number of benefits which enables transition to the modern energy infrastructure. “Smart Power Generation” is a sustainable, affordable and efficient way to optimize complete energy system. Wärtsilä India held a press briefing in Mumbai as an initiative to provide a perspective for the 12th Five Year Plan. Renewable, Nuclear, Coal, Natural Gas generation, demand side management & Smart Grids have their role to play, but no single technology is a solution in isolation. An integrated approach to look at the Power Sector is of vital importance. “Smart Power Generation” is an important part of the equation to get sustainable, reliable & affordable power to all. A study conducted in association with IIT Delhi, indicates that Smart Power Generation can provide solution for some of the major issues confronting the Power Sector, such as: . a)Coal & Natural Gas availability: Smart power generation brings 6,9% efficiency in over all fuel mix of the country which in turn also reduces problems in coal availability and saves Rs 4,500 Cr/annum in primary fuel cost. 6,9% of overall saving would mean a substantial plugging of the supply demand gap envisaged for new coal based plants. Further, the concept would provide almost 4 times the MW addition for gas based plants to run as Peaking Plants with the same quantity of gas. This would 046 » September - October 2011 » Construction And Architecture Magazine be an important dimension looking at natural gas availability constraints & also its relatively higher price. Land requirement for such generation is less than 1/10th of a coal based power plant thus saving of >24000 acres of land ( > Rs 6000 Crore ) and negligible water consumption saves 410MnCu Mn water, which is equivalent to the annual need of a city like Mumbai. Wind and Solar power integration: Supports wind and solar plants infirm nature of energy with power through its quick response plants. Load shedding - An independent study shows that that INR 1,00,000 crore has been invested on power back-up equipment so far, while an additional INR 30,000 crore is spent every year as operational expense on generating back-up power. The value of lost load (VOLL) cost significant amount of money & inefficiencies in the country, for Maharashtra assessed at Rs 17,000 crore per annum. Peak - load management will ensure continuous reliable supply power at a minimal increase in the unit cost. Environment - Optimization of power generation mix with base load generation & peak load generation plants along with renewable generates a CO2 savings of ~100MN tonnes by end of 12th 5 year plan, valued at ~ 9,700 Cr in the Carbon market. This amounts to almost 10% reduction in overall CO2 generation in power sector. Time to the market for capacity addition: With a modular design, it takes only 12 – 15 months power out from financial closure.In overall terms, introduction of Smart Power Generation concept in the country's power generation mix has a potential to save to the tune of Rs.46,000Cr capex in the 12th Five Year Plan period and Rs.14,000Cr per annum of operating costs. Maharashtra's demand for uninterrupted power supply presents a great opportunity for growth. The state is poised to be a prominent energy hub for India. The transition to a sustainable energy infrastructure requires a judicial mix of Base Load with Coal & Nuclear, Renewables & Load Centre based natural gas Peaking Power Plants. It is highly recommended to plan & segregate the MWs coming from these three categories of generation. Smart Power Generation is a highly efficient, flexible and economic solution for optimizing power systems & it is high time to integrate such solution in the country's energy mix. MCF power plant completes 25 years of non-stop operations Wärtsilä India has announced that the power plant at Mangalore Chemicals & Fertilizers Ltd (MCF) in Karnataka has completed 25 years of successful and continuous operations. The power plant has eight Wärtsilä 18V32 engines with a total generation capacity of 48MW, of these two engines have completed about 150,000 running hours, three machines about 140,000 hours and three machines about 100,000 hours. This is an important milestone for both MCF and Wärtsilä India as it signifies a long-standing successful partnership between the two companies. At a felicitation event organised today at the plant's site, Wärtsilä India representatives acknowledged the support of MCF towards accomplishing this outstanding feat. The Wärtsilä DG Power Plant was commissioned in 1985 to overcome the frequent interruptions in power supply, which were causing equipment failure and wastage of energy during shut-down and start-up of the plant within the factory. The Wärtsilä power plant has ensured smooth operation of the fertilizer plant through the steady supply of quality captive power. This power plant meets the total power needs for the entire factory. Mangalore Chemicals & Fertilizers Limited in brief Mangalore Chemicals & Fertilizers Limited (MCF), with a turnover of Rs.2081.73 crore (for the year 2009-2010) is the only manufacturer of chemical fertilizers in the state of Karnataka. The factory is strategically located at Panambur, 9 kms north of Mangalore City. The plant was commissioned on March 15, 1976. The company is a part of the UB Group with group shareholding of 30.44%. Dr. Vijay Mallya is the Chairman of the Board of Directors. MCF has the facility at Mangalore to manufacture annually 217,800 MT of ammonia, 379,500 MT of urea, 260,000 MT of phosphatic fertilizers (DAP and NP 20:20:00:13), 15,330 MT of ammonium bi-carbonate (ABC), 33,000 MT of sulphuric acid (SAP) and 21450 MT of Sulphonated Naphthalene Formaldehyde (SNF) and has other infrastructural facilities to import fertilizer and liquid feed stocks. 048 » September - October 2011 » Construction And Architecture Magazine

- 6. Cover Story : Cover Story : India's mega projects India's mega projects Renowned for creating engineering milestones A Afcons in its glorious journey of over five-decades has many firsts to its credit. It was the first Indian construction company to have constructed an underground metro station fcons Infrastructure Private Limited is renowned for creating engineering milestones, ever since its inception in 1959. Afcons in its glorious journey of over five-decades has many firsts to its credit. It was the first Indian construction company to have constructed an underground metro station (at Barakhamba Road, New Delhi), one of only four qualified bidders for construction of Reactor Buildings in the country. Among many others, Afcons' two megaprojects in India which stand out for their enormity, uniqueness in terms of design/ construction and can have significant socio-economic impact once the construction is complete, are1. Design and const. of special bridge across the river Chenab in Jammu & Kashmir (Value- Rs 5.88 Billion) 2. Chennai Metro - Package 1 & 5 (Value- Rs 26 Billion) Chenab Bridge The construction of Chenab Bridge is considered as a major step to improve connectivity and economic infrastructure in Jammu & Kashmir. The site is located in the Katra Laole section of Jammu-Udhampur-Baramullah Rail Link project which is of prime national importance in view of the role that it would play in integrating the socio-economic life in the Kashmir Valley with other parts of nation. The bridge will put the valley on the railmap of India and provide multimodal transportation facilities to the people of the region. The proposed bridge on the Chenab River, upstream of Salal Dam is situated near Kauri Village. The railway line crosses the river at about 359m above the river bed level. The total length of the bridge is 1315m consisting of an arch span of 469m across the Chenab. Northern Railway owns the total project and Konkan Railway Corporation is executing the project on behalf of Northern Railway. The bridge has to be designed and constructed considering many parameters that are unique to this bridge. Some of the considerations are the high wind forces, location of the bridge in highly active seismic zone of India, possibility of terrorist attacks, provision for future track, continuous monitoring systems etc. All the features of this bridge make it unique and once completed it will be the tallest bridge in the world, soaring 359 m above the river bed. The main span of the Chenab Bridge is proposed as an arch, made from large steel trusses. The chords of the trusses will be sealed steel boxes, filled with concrete to assist in controlling wind-induced forces on the bridge. The boxes will be stiffened internally. The designers have considered the aesthetic merit of the bridge and made a strong attempt to bring a natural cadence to the site. Salient Design and Construction Features: Bridge to be designed for double lines for MBG loading as per IRS code. To be designed for heavy wind pressure and earthquake zone V as per the relevant IS codes. Seismic analysis considering various modes of vibration shall be carried out for site-specific response spectra. A study for the same was done by IIT, Roorkee. To be designed by fatigue consideration in consonance with requirement of BS 5400. Bridge to be designed and checked for adequacy at various stage of construction so that partially completed structures are sturdy enough to resist the effect of wind / earthquake and unforeseen forces. Bridge critical members will be designed for adequate redundancy and operation at the lower level of efficiency. Bridge will also be designed for blast loading IS 4991 – 1968. 050 » September - October 2011 » Construction And Architecture Magazine The provision of permanent mechanical cages for inspection of high trestles/ piers. Bridge will be provided with warning system such as anemometers, accelerometers, temperature monitors, central control to monitor the induced strains due to wind and seismic loads through computerized systems with automatic comparison with permitted limits of designs Corrosion preventive measures All welded connections shall be made in the fabrication shop while all the field connections shall be with High Strength Friction Grip Bolts. For the Chenab Bridge, there is a greater emphasis on the structural response to wind forces. Wind Tunnel Tests were conducted at Force Technology Laboratory, Norway to establish the topographic effects of the site on the reference wind speed; the static force coefficients; the occurrence of any aero-elastic effects such as vortex shedding, galloping and flutter; the effects of gust-buffeting. The design of the bridge is being carried out as per the approved design basis note prepared specially for this bridge drawing the experiences gained from various projects abroad and international codes and practices. BS:5400 is the basic platform on which the design and construction of the Chenab Bridge will be carried out. World over bridges are incrementally launched either on straight alignment or on curved alignment of uniform radius. Never the bridges are incrementally launched from one end when the bridge is partly on straight and partly on curve and more so when the bridge is on transition curve with varying radius. The deck on the viaduct of Chenab Bridge is partly in straight, partly in circular curve and partly on transition curve. This is first time in the world that incremental launching is attempted on a transition curve. The arch span will be constructed using cable cranes and derrick moving on the already erected portion of the viaduct. Chennai Metro Project Chennai is the 4th largest metropolitan city in India. Chennai often known as the Detroit of Asia is widely known for its presence in the automotive industry and has attracted several global automakers to setup their factories in the city becoming one of the global leaders in the industry. Apart from automobiles, it also has development centers set up by many software companies, making it the secondlargest exporter of software in the country, behind Bangalore. Based on all these industrial and technological advancements, urban population has risen rapidly, requiring need for faster and safer transportation at all times. The city already has multiple modes of transportation. A bus system is run by the Chennai MTC and is augmented by the Chennai suburban railway network run by the Southern Railway. In addition to this, the Chennai Corporation has also implemented the Chennai MRTS project; an elevated railway system was sanctioned in 1984 to ease congestion in central Chennai. However, traffic congestion was still a big problem for both the citizens as well as the City's governing body. Chennai Metropolis has been growing rapidly and the traffic volumes on the roads have also been increasing enormously. Hence the need for a new rail based rapid transport system has been felt and towards this objective the Government of Tamil Nadu has decided to implement the Chennai Metro Rail Project. This project aims at providing the people of Chennai with a fast, reliable, convenient, efficient, modern and economical mode of public transport, which is properly integrated with other forms of public and private transport including buses, suburban trains and MRTS. The Transtonnelstroy-Afcons JV has secured two packages as Contract:UAA01 & Contract UAA05 with value of Rs. 1567 Crores & Rs. 1031 Crores respectively and the work has begun. M/s Parsons Brinckerhoff India (P) Ltd is the designer for the project. Chennai Metro Project is rapid transit rail system. The project will be implemented in a phased manner. The phase 1 consists of two Corridors under construction. Corridor 1 is from Meddavaram to St. Thomas Mount and Corridor 2 is from Madhavaram to Lighthouse via Radhakrishnan Salai. About 55% of corridors in Phase 1 are underground and balance is elevated. The total length of twin tunnel is 18.75 km and 19 underground stations will be built. The major portion of tunnel will be executed by using the Tunnel Boring Machine (TBM). The Package UAA01 lies in Corridor 1 and UAA05 lies in Corridor 2 of Chennai Metro Project. Package UAA01 starts from Washermanpet to Egmore station and package UAA05 starts from Shenoy Nagar to Thiurmangalam. The length of twin tunnel with TBM technique for UAA01 & UAA05 is 5.5 km & 3.1 km respectively. 5 Underground stations & 4 underground stations are to be constructed for UAA01 & UAA05 respectively. The construction works for Chennai Metro Project by Transtonnelstroy-Afcons JV is already started and will be completed by end of April 2015. 052 » September - October 2011 » Construction And Architecture Magazine