B321

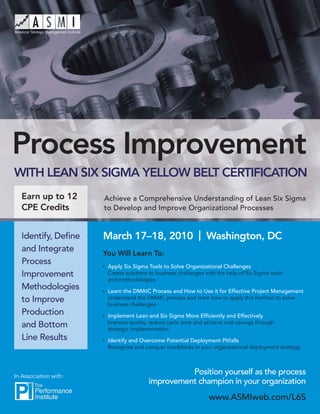

- 1. Process Improvement WITH LEAN SIX SIGMA YELLOW BELT CERTIFICATION Earn up to 12 Achieve a Comprehensive Understanding of Lean Six Sigma CPE Credits to Develop and Improve Organizational Processes Identify, Define March 17–18, 2010 | Washington, DC and Integrate You Will Learn To: Process Apply Six Sigma Tools to Solve Organizational Challenges Improvement Create solutions to business challenges with the help of Six Sigma tools and methodologies Methodologies Learn the DMAIC Process and How to Use it for Effective Project Management to Improve Understand the DMAIC process and learn how to apply this method to solve business challenges Production Implement Lean and Six Sigma More Efficiently and Effectively Improve quality, reduce cycle time and achieve cost savings through and Bottom strategic implementation Line Results Identify and Overcome Potential Deployment Pitfalls Recognize and conquer roadblocks in your organizational deployment strategy In Association with: Position yourself as the process improvement champion in your organization www.ASMIweb.com/L6S

- 2. For organizations to consistently improve their performance, it is critical that the people doing the work have the skills and tools necessary to apply their knowledge to the improvement process. The goal of this course is to provide professionals with techniques to continuously improve individual and team work by contributing effective solutions in problem solving projects. Yellow belt recipients will leave the workshop with the tools necessary to: Apply Support Document Work Complete learned techniques the identification “best practices” to ensure the a work related to help make of improvement in a manner that gains of successful project improvement in opportunities will enable them to projects are the daily work of through a team be disseminated maintained your function area problem solving throughout your by collecting data, process organization applying the tools and using the problem solving process 2 www.ASMIweb.com/L6S

- 3. Process Improvement Training March 17, 2010 day one 8:00 12:00 Workshop Registration and Continental Breakfast Lunch 9:00 1:00 Welcome Remarks and Introductions Manage the Lean Six Sigma Project Streamline Lean Six Sigma and project Introduction to Lean Six Sigma management strategies History and background of Lean and Apply measurement tools to evaluate projects Six Sigma (LSS) and objectives Outcomes of LSS Core concepts and goals of LSS 2:30 Break LSS infrastructure The DMAIC methodology 2:45 Define 10:30 Define problem Break Define improvement goal 10:45 Initiation of process mapping process (SIPOC) DMAIC-Pizza Service Simulation Select team Prioritizes improvement opportunities Create project plan and countermeasures Draft project charter Provides for a thorough analysis of the opportunity 3:30 Establishes a consistent approach Summary & Daily Wrap Up Enhances employee development 4:00 and motivation Day One Adjourns Implementation and Deployment Strategy Develop strategies and objectives “The benefits of this for deployment Incorporate Six Sigma into organizational conference will help me business strategy Identify key focus areas and change deploy projects and aim management processes for better performance.” Create flexibility and responsiveness in your organization – Paul Scofield, Premiere Global who should attend? CEOs Lean Six Sigma Deployment Leaders CIOs Lean Six Sigma Champions COOs Head of Quality VP/Director of Process Improvement …and anyone participating in Six Sigma VP of Business/Operational Excellence or process improvement Head of Operations www.ASMIweb.com/L6S 3

- 4. Process Improvement Training March 18, 2010 day two 8:30 12:00 Continental Breakfast Lunch 9:00 1:00 Measure Focus on Projects Baseline the current process Charter Address “low-hanging fruit” Stakeholder analysis Confirm customer CTQs Communication plan Determine current performance baseline Process map Stratify data Cause and effect FMEA Analyze Solution matrix Gather causal data WBS/schedule Determine & validate root causes Control plan Identify a solution to combat root causes 2:30 Break 10:30 Break 2:45 10:45 Review/Questions Improve 3:15 Identify countermeasures Exam Perform cost/benefit analysis Design improved process 4:00 Develop scorecards Day Two Adjourns Pizza Service Simulation Two & Control Report scorecard data Create process control plan Identify replication opportunities Develop future plans top five reasons to attend: Evaluate voice Dissect your Eliminate Create sound Improve the of the customer processes to non-value added metrics to quality of service techniques that achieve dramatic steps in your measure every and engage enhance customer improvements in processes and phase of the leadership to satisfaction waste reduction decrease variation improvement drive continuous to improve process improvement process 4 www.ASMIweb.com/L6S

- 5. Process Improvement Training In-House Training & Customization One of the more popular vehicles for accessing the Institute’s educational offerings is the delivery of on-site trainings and management facilitations. Bringing a training or facilitation in-house gives you the opportunity to customize a program that addresses your exact challenges and provides a more personal learning experience, while virtually eliminating travel expenses. Whether you require training for a small group or for an organizational-wide initiative, the advanced learning methods employed by the Institute will create an intimate training atmosphere that maximizes knowledge transfer to enhance the talent within your organization. Customization: We realize that not all obstacles can be overcome by applying an “off-the-shelf solution”. While many training providers will offer you some variation of their standard training, the Institute’s subject matter experts will work with you and your team to examine your programs and determine your exact areas of need. The identification of real life examples will create a learning atmosphere that resonates with participants while at the same time providing immediate return on your training investment. Using interactive exercises that employ actual projects or scenarios from your organization, instructors can address specific challenges and align the curriculum of each session to your objectives. While the majority of on-site trainings are focused on smaller groups, the Institute also has the ability to accommodate organizational-wide training initiatives. Utilizing multiple instructors, the Institute has the capacity to deliver courses to groups of up to 300 participants per day. Areas of Expertise: On-site delivery of single courses, certification programs and entire packages of specialized courses are available in the following areas: • Strategic Planning • Performance Measurement • Project Management • Lean Six Sigma “I will now be able to • Workforce Management • Budgeting and Forecasting apply Lean Six Sigma • Contracting techniques and tools to • Performance Reporting • Program Evaluation measure activities.” • Administrative Management – Katherine Grueneberg, Dental Associates, LTD. • Change Management • Balanced Scorecard For more information about in-house training and certification options, please contact Blake Zach at 877-992-9522 or Blake.Zach@ASMIweb.com. www.ASMIweb.com/L6S 5

- 6. Process Improvement Training Logistics & Registration Venue and Hotel: Cancellation Policy: Process Improvement with Lean Six Sigma Yellow For live events: ASMI will provide a full refund less $399 administration Belt Certification will be held at The Performance fee for cancellations four weeks before the event. If cancellation occurs Institute Conference Center in Arlington, VA, just within two weeks prior to conference start date, no refund will be issued. Registrants who fail to attend and do not cancel prior to the event will be one block east of the Courthouse Metro stop on the charged the entire registration fee. Orange Line. A public parking garage is located just inside of the building for $10/day. For webinars: ASMI will provide a full refund less $50 administrative fee for cancellations four weeks before the event. If cancellation occurs within two weeks prior to conference start date, no refund will be issued. Registrants The Performance Institute Training Center who fail to attend and do not cancel prior to the meeting will be charged 1515 N. Courthouse Rd., Suite 600 the entire registration fee. Arlington, VA 22201 877-992-9521 All the cancellation requests need to be made online. Your confirmation email contains links to modify or cancel registrations. Please note that the cancellation is not final until you receive a written confirmation. A limited number of rooms have been reserved at the Arlington Rosslyn Courtyard by Marriott Payment must be secured prior to the conference. If payment is not at the prevailing rate of $209 until February 17, received by the conference start date, a method of payment must 2010. Please call the hotel directly and reference be presented at the time of registration in order to guarantee your participation at the event. code “Yellow Belt Certification” when making reservations to get the discounted rate. The hotel is conveniently located three blocks from Quality Assurance: the Rosslyn Metro station. Please ask the hotel ASMI strives to provide you with the most productive and effective educational about a complimentary shuttle that is also experience possible. If after completing the course you feel there is some way available for your convenience. we can improve, please write your comments on the evaluation form provided upon your arrival. Should you feel dissatisfied with your learning experience Arlington Rosslyn Courtyard by Marriott and wish to request a credit or refund, please submit it in writing no later than 10 business days after the end of the training to: 1533 Clarendon Blvd. Arlington, VA 22209 ASMI Corporate Headquarters: Quality Assurance Phone: 703-528-2222 / 1-800-321-2211 805 15th Street NW, 3rd Floor www.courtyardarlingtonrosslyn.com Washington, DC 20005 Note: As speakers are confirmed six months before the event, some speaker changes or topic changes may occur in the program. ASMI is not Tuition & Group Discounts: responsible for speaker changes, but will work to ensure a comparable speaker is located to participate in the program. The tuition rate for Process Improvement with Yellow Belt Certification is as follows: If for any reason ASMI decides to cancel this conference, ASMI accepts no responsibility for covering airfare, hotel or other costs incurred by registrants, including delegates, sponsors and guests. Offerings Early Bird Regular Rate Conference $999* $1099 Discounts: For more information on group discounts for Process • All ‘Early Bird’ Discounts must require payment at time of registration and Improvement with Lean Six Sigma Yellow Belt before the cut-off date in order to receive any discount. Certification please contact: • Any discounts offered whether by ASMI (including team discounts) must also require payment at the time of registration. Paul Rogers at 858-866-9386 or email him at • All discount offers cannot be combined with any other offer. Paul.Rogers@ASMIweb.com. • Discounts cannot be applied retroactively Exhibiting & Sponsorship: To learn more about exhibiting and sponsorships at Process Improvement with Lean Six Sigma Yellow Belt Certification, please contact: Meredith Mason at 202-739-9707 or email her at Meredith.Mason@PerformanceInstutite.org 6 www.ASMIweb.com/L6S

- 7. Process Improvement Training Logistics & Registration to register Call Fax this Form to Visit 877-992-9522 866-234-0680 www.ASMIweb.com/L6S Registration Form Yes! Register me for Process Improvement with Lean Six Sigma Yellow Belt Certification Please call me. I am interested in a special Group Discount for my team Delegate Information Name Title Organization Dept. Address City State Zip Telephone Fax Email Payment Information Check Purchase Order / Training Form Credit Card Credit Card Number Expiration Date Verification no. Name on Card Billing Zip Please make checks payable to: The Performance Institute Priority Code: B321-WEB www.ASMIweb.com/L6S 7

- 8. ASMI’s vision In this challenging economic landscape, organizations must develop and execute innovative strategies to survive and thrive. Performance and process improvement methodologies give managers the tools they need to run leaner, more efficient businesses. The mission of the American Strategic Management Institute (ASMI) is to connect business leaders with best-in-class practices and training to address management challenges and improve results. ASMI has grown into one of the nation’s most innovative training providers, combining market research and industry insight to deliver experiences and tools to inspire leaders and grow businesses. Through virtual sessions, national summits, training programs and consulting services, ASMI brings together leaders to share insights, ideas and actions to transform organizations. Areas of Focus: Performance Management: Using business analytics to drive strategy Process Improvement: Leaning processes for efficiency and quality improvement Financial Management: Budgeting and forecasting for better decision-making Project Management: Managing projects to deliver results on time, within scope and in budget Leadership Development: Building leadership skills to manage in times of change and conflict Services: Virtual Training Briefings 90-minute training sessions for the latest tools and techniques to deliver results. National Summits National events allowing business leaders to share best practices and strategies for success. Training Programs Methodology-based training modules in management competencies, offered publicly or custom-designed for your organization Consulting Services Field experts who can bring bold change to your workforce planning processes. ASMI Corporate Headquarters 805 15th Street, NW, 3rd Floor Washington, DC 20005 Ph: 877-992-9522 Fax: 866-234-0680 www.ASMIweb.com