magil_sg_adam_jd_et_al_-_development_of_a_biopharm_aceutical_is_complex

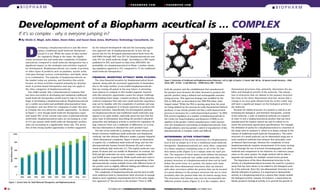

- 1. both the product and the establishment that manufactured the product were licensed; the latter licensed to produce the specific product using a defined and unchangeable manufac- turing process. This approval strategy was modified by the FDA in 1996 and, as described in the 1996 PDA letter, John Geigert stated “While the FDA is moving away from the prod- uct being defined by the process for well-characterized biotech products, it was clearly pointed out that a well-characterized process is necessary for a well-characterized product.” In 2002, FDA moved regulation of a number of biopharmaceuticals to the Center for Drug Evaluation and Research (CDER) in rec- ognition of the greater control manufacturers could exercise over the manufacture and testing of biopharmaceuticals. Even though industry now has greater control of manufacture of bio- pharmaceuticals, it remains costly and difficult. Determining Active Structures Determination of the active structures of a biopharmaceu- tical is not as simple as it is for a traditional small molecule therapeutic. Biopharmaceuticals are, most often, comprised of a linear sequence containing some or all of the 20 com- mon amino acids (Figure 3) in a unique order for each pro- tein. The sequence of these amino acids defines the primary structure of the molecule but, unlike small molecules, the primary structure of a biopharmaceutical does not by itself define the active form. In a protein, the amino acid chain folds into three-dimensional structures that can interact with other structures within the protein that can be located at a great distance in the primary structure but are in close proximity after the protein folds into its lowest energy form. The structures that interact may even be incorporated into different protein chains (Figure 4). It is the complex, three D eveloping a biopharmaceutical is just like devel- oping a traditional small molecule therapeutic… except it is not. While the types of data needed for regulatory filings is the same, the signifi- cantly increased size and molecular complexity of biophar- maceuticals compared to small molecule therapeutics has a significant impact on the strategies and activities required for development. Biopharmaceuticals can consist of proteins or other types of products such as peptides, nucleic acids, viral gene therapy vectors, carbohydrates, and lipids, alone or in combination. The majority of biopharmaceuticals on the market today are proteins, and therefore this article focuses on those activities required primarily for develop- ment of protein-based therapeutics and may not apply to the other categories of biopharmaceuticals. One might wonder why a pharmaceutical company that has been successful in developing and marketing traditional small molecule therapeutics would want to take on the chal- lenge of developing a biopharmaceutical. Biopharmaceuticals are a widely successful and profitable pharmaceutical class of products, and one driver for companies to enter this area is certainly the very attractive market opportunity. As shown in Figure 1, even though small molecule therapeutics repre- sent nearly 90% of the current total sales of pharmaceuticals world-wide, biopharmaceutical sales are increasing at a rate of 11% per annum while small molecule therapeutic product sales are increasing at a significantly lower rate. The attrac- tion of this strong market opportunity is further supported by the reduced development risk and the increasing regula- tory approval rate of biopharmaceuticals. In fact, the ap- proval rate for the 50 largest pharmaceutical firms from the mid-1990s through 2007 was 32% for biopharmaceuticals and only 19% for small molecule drugs1 . According to a BIO study published in 2011 and based on data from 2004-2010, the probability of a biopharmaceutical in Phase 1 studies obtain- ing regulatory approval is 15% compared to 7% for traditional small molecule therapeutics.2 Financial Incentives Attract More Players The clear financial incentive for biopharmaceutical devel- opment, along with the increased opportunity in biosimilars due to the large number of successful biopharmaceuticals that are coming off patent in the near future, is attracting more players to compete in this market segment; however with this attractive opportunity comes the unique challenge of developing these larger, complex products. Many pharma- ceutical companies that only have small molecule experience may not be familiar with the complexity of proteins and may not have the equipment or in-house expertise to perform the required activities. Superficially, the development pathway for biopharmaceuticals and traditional small molecules may appear to be quite similar, especially given the fact that the same type of information describing the product’s physical properties and biological activity is needed for regulatory fil- ings; however there are a multitude of differences as to how this key information is obtained for each product type. The size of the molecule is, perhaps, the most obvious dif- ference between traditional small molecules and biopharma- ceuticals, but this obvious difference masks a greater disparity –three dimensional complexity. Figure 2 shows an illustration of aspirin (A), a traditional small molecule drug, and two bio- pharmaceuticals, human Growth Hormone (B) and a mono- clonal antibody (IgG molecule) (C). The aspirin molecule com- prises 20 atoms and can readily be illustrated. In contrast, the hGH and IgG molecules are more complex, comprising 3,000 and 20,000 atoms, respectively. While small molecules exist in single molecular compositions, even pure preparations of bio- pharmaceuticals contain multiple forms with different forms of the protein such as slightly different folding and different and multiple post-translational modifications. The complexity of biopharmaceuticals and the lack of suffi- cient analytical tools to characterize their structure in enough detail to meet regulatory requirements led to the early regula- tory approach of “the process is the product.” Prior to 1996 Development of a Biopharm aceutical is … Complex n By Sheila G. Magil, Julia Adam, Dawn Ecker, and Susan Dana Jones, BioProcess Technology Consultants, Inc. n 32 october 2012 | Pharmaceutical Processing n p h a r m p r o . c o m n b i o p h a r m dimensional structures that, primarily, determines the sta- bility and biological activity of the molecule. The interac- tion of structures that are distant in the primary structure but close in the three dimensional structure means that a change in an area quite distant from the active center may still have a significant impact on the biological activity of the molecule. Because the folded structure of a protein is critical to de- termining the biological, and therefore therapeutic, activity of the molecule, a suite of analytical methods are required in order to test a biopharmaceutical product that has been manufactured for human clinical use and to release it if it meets the previously agreed-upon specifications. For example, the definition of purity for a biopharmaceutical is a function of the assay used to measure it, which is in sharp contrast to the release of traditional small molecule therapeutics. The entire structure of a small molecule can be determined using one or more analytical methods that measure first principles, such as Infrared Spectroscopy, whereas the complexity of most biopharmaceuticals requires measurement of its many varying forms through the use of several chromatographic and other methods and comparison to the behavior of a reference prepa- ration in the same system. No single method will be able to separate and quantify the multiple variant forms present. The importance of the three dimensional structure in the activity of a biopharmaceutical increases the need for a potency assay that has been shown to be related to the biological activ- ity of the molecule. Since the ‘one-dimensional’ structure is not directly indicative of potency, it is important to demonstrate activity of a biopharmaceutical in a system that closely models the biological activity. Assume, for instance, a monoclonal an- tibody product’s biological activity is to prevent the growth of Pharmaceutical Processing | october 2012 33 n n p h a r m p r o . c o m n b i o p h a r m If it's so complex - why is everyone jumping in? Figure 1. Current Sales for Small Molecule Therapeutics and Biopharmaceuticals Figure 2. Illustration of Traditional and Biopharmaceutical Molecules. Left to right: A) Aspirin, 21 Atoms, MW 180 Da. B) Human Growth Hormone, ~3000 Atoms, MW ~22 kDa . C) IgG Molecule, ~20000 Atoms, MW ~150 kDa A CB

- 2. Figure 3. Twenty Common Amino Acids blood vessels that supply oxygen and nutrients to tumors in a cancer patient. It is insufficient to simply demonstrate that the antibody binds to its target, such as human vascular endothe- lial growth factor (VEGF), with an ELISA assay. It is also necessary to demonstrate that bind- ing of the monoclonal antibody to this target also reduces VEGF binding to and activation of the VEGF receptor molecule, and therefore reduces blood vessel formation and growth, in a dose-dependent manner. Complexity Issues The structural complexity of a biophar- maceutical also impacts the development of the purification process that will be used to manufacture the product for human clinical use. Impurities in a purified preparation of a protein can be related to the production process (process related impurities) or to the molecule (product related impurities). In general the process related impurities are quite different from the product and are more easily removed by chromatographic methods. Product related impurities are closely related to the product and therefore can be much more difficult to remove during purification. Product-related impurities can consist of, in part, misfolded forms, aggregates, or trun- cated versions that were not completely syn- thesized or that were cleaved by a protease during production. An additional constraint on the purification of biopharmaceuticals is the need to maintain the structure, which often requires working in an aqueous environ- ment under relatively mild conditions. The complexity of a biopharmaceutical also impacts determination of stability, making this evaluation more difficult than for traditional small molecule therapeutics. The composi- tion of a traditional small molecule is a single molecule with a single structure; and as stated previously, a pure biopharmaceutical can con- tain multiple forms. Small molecule degrada- tion, involving one kind of molecule proceeds according to first order kinetics and the deg- radation rate at standard storage conditions can be estimated with good accuracy by the Arrhenius equation. Unfortunately, degrada- tion pathways and degradation rates are not as simple for proteins. A pure biopharmaceuti- cal may contain a large number of molecular types and therefore it degrades according to second or higher order kinetics. Each of these forms may degrade according to slightly differ- ent kinetics and pathways, and the interaction of the multiple forms may influence the degra- dation of each. The stability of a biopharma- ceutical can only be determined, according to current regulatory guidelines, using real time studies conducted under real, intended stor- age conditions. In addition, since there may be some slight differences in impurities present at full commercial production scale compared to those present at lab or pilot scale, stability information from batches produced at smaller scales are considered to be supporting infor- mation and not sufficient for expiry dating of product produced at full commercial scale. More Challenges Other challenges in developing a biophar- maceutical include immunogenicity and com- parability testing. In contrast to biopharma- ceuticals, traditional small molecules are not considered to be immunogenic due to their small size, and therefore immunogenicity test- ing is not part of the development pathway for a traditional small molecule therapeutic. Biopharmaceuticals are largely considered to be immunogenic, even if completely equiva- lent in sequence to a native human protein, because the potential for differences in struc- ture and mode of administration may give rise to an immune reaction. Consequently, n p h a r m p r o . c o m n b i o p h a r m evaluation of immunogenicity during clinical trials is a requirement for biopharmaceutical development. Determination of comparabil- ity for biopharmaceuticals is of significant concern during development. During scale up of the manufacturing process it is necessary to demonstrate that production changes do not result in critical changes in the molecu- lar structure that could impact potency or immunogenicity. With the recent legislation (Biologics Price Competition and Innovation Act) allowing for the development of biosimi- lars, demonstration of structural comparabil- ity between the innovator biopharmaceutical and the biosimilar will be crucial. Differences in the development of biophar- maceuticals and traditional small molecule therapeutics can be traced to the disparate complexity of these two molecule classes. Demonstration of small molecule structure can be done using analytical methods whose first principles are well understood and the testing results are readily interpreted. Structural analysis of biopharmaceuticals is not simple and the testing results are more difficult to interpret. The majority of the challenges in the development of a biophar- maceutical result from its complexity. This same complexity will also make development of biosimilars much more challenging than the development of generic versions of suc- cessful small molecule therapeutics. References 1 DiMasi JA, et al. Trends in risks associ- ated with new drug development: success rates for investigational drugs. Nature. 2010 Mar;87(3):272-7. 2 Hay M, et al. BIO / BioMedTracker: Clinical trial success rates study. Presented at the Biotechnology Industry’s 14th Annual CEO and Investor’s Conference; 2011 Feb 14-15; New York, New York. 3 Figure adapted from: Bioprocess Technology Consultants [Internet]. Woburn (MA): Bioprocess Technology Consultants, Inc. Biomanufacturing supply pipeline product databases; 2011 [cited 2012 Aug 31]; [about 2 screens]. Available from: http://www.bptc.com/pipeline-databases. php and IMS Health Inc. Total unaudited and audited global pharmaceutical market, 2003 – 2011 [Internet]. Parsippany (NJ): IMS Health, Inc.; 2012 May [cited 2021 Aug 31]. 1p. Available from: http://www. imshealth.com/deployedfiles/ims/Global/ Content/Corporate/Press%20Room/Top- Line%20Market%20Data%20%20Trends/ 2011%20Top-line%20Market%20Data/Global_ Pharma_Market_by_Spending_2003-2011.pdf. 4 Aspirin [Internet]. San Francisco (CA): Wikipedia, The Free Encyclopedia; 2001 Nov 6 [updated 2012 Aug 28]. File:Aspirin- B-3D-balls.png; 2008 May 15 [cited 2012 Aug 29]; [about 4 screens]. Available from: http://en.wikipedia.org/wiki/File:Aspirin-B- 3D-balls.png. 5 Growth hormone [Internet]. San Francisco (CA): Wikipedia, The Free Encyclopedia; 2001 Nov 6 [updated 2012 Aug 28]. File: Somatotropine.GIF; 2005 Aug 25 [cited 2012 Aug 29]; [about 4 screens]. Available from: http://en.wikipedia.org/wiki/File: Somatotropine.GIF#file 6 Protein structure [Internet]. San Francisco (CA): Wikipedia, The Free Encyclopedia; 2001 Nov 6 [updated 2012 Aug 28]. File: Main_protein_structure_levels_en.svg; 2008 Oct 7 [cited 2012 Aug 29]; [about 4 screens]. Available from: http://en.wikipedia.org/wiki/ File:Main_protein_structure_levels_en.svg n Figure 4. Structural Motifs of Biopharmaceuticals n p h a r m p r o . c o m n b i o p h a r m n 34 october 2012 | Pharmaceutical Processing