Module 4 review-questions_solved

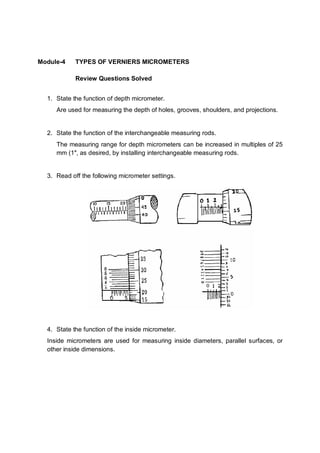

- 1. Module-4 TYPES OF VERNIERS MICROMETERS Review Questions Solved 1. State the function of depth micrometer. Are used for measuring the depth of holes, grooves, shoulders, and projections. 2. State the function of the interchangeable measuring rods. The measuring range for depth micrometers can be increased in multiples of 25 mm (1″, as desired, by installing interchangeable measuring rods. 3. Read off the following micrometer settings. 4. State the function of the inside micrometer. Inside micrometers are used for measuring inside diameters, parallel surfaces, or other inside dimensions.

- 2. 5. What is the difference between inside micrometer and tubular inside micrometer? Inside micrometers are used for measuring inside diameters, parallel surfaces, or other inside dimensions. Tubular inside micrometers are highly useful tools for internal linear measurements such as measuring cylinders, rings, setting calipers, comparing gages, and measuring parallel surfaces. 6. State the type of micrometers used for measuring: a. parallel surfaces Inside micrometers b. inside diameters of 300 mm Tubular inside micrometers c. small holes Inside micrometers 7. Identify the principal parts of the shown micrometer.

- 3. 8. Explain the function of: Ratchet: With the use of the ratchet, a consistent pressure can be applied on the spindle when measurement is made Lock nut: The lock nut locks the spindle in position after measurements are made. Changeable anvils: The digital interchangeable anvil micrometers may be used for measurements in the range from 225.300 mm (9" to 12") simply by changing and installing the appropriate anvil. 9. Read off the following micrometer settings:

- 4. 10. List the recent design micrometers and state their functions. Micrometers today are available with many different capabilities, accuracies, and applications in mind. The newest micrometers have direct-reading capabilities to 0.00001 inch. Several micrometers of more recent design include the following: 1. Indicating micrometer, which can also be used as a comparator for quickly checking parts in quantity; 2. Direct reading micrometer, which provides a numerical display of the micrometer reading; 3. Dual reading micrometer, which reads both in metric and in English measurements; and 4. All electronic micrometers, which has a motorized spindle and electronic digital readout. 11. Explain the method of measuring thread major diameter using micrometer.

- 5. 12. Explain the method of measuring thread minor diameter using micrometer. - The pitch diameter of 60° V-threads may be measured directly with a thread micrometer. - The spindle of the micrometer has a 60° conical point, and the anvil has a 60° groove. - The anvil points swivels to enable measurement of different - pitches. 1. The micrometer always should be checked for a zero reading before measuring threads. 2. Hold the micrometer correctly; the 1-inch and 2-inch sizes in one hand so that the thumb, index finger, and third finger turn the spindle, while the fourth and fifth fingers clamp -the frame against the palm of the hand. 3. The larger sizes of micrometers are manipulated with two hands Sometimes there are special measuring conditions where, even with smaller range micrometers, it is more convenient to use both hands. 4. Avoid excessive handling. The heat of the hands will cause expansion resulting in inaccuracies. 5. Use the ratchet where fitted to give uniform pressure to ensure consistent readings. 6. Ensure that the anvils are flat against surfaces of piece being measured.