Global Supply Chain Security Policy

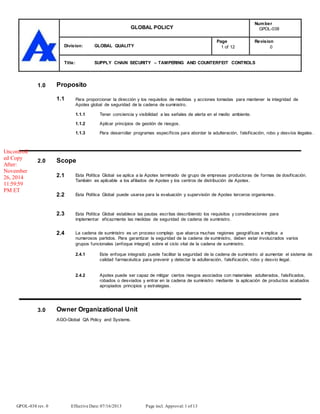

- 1. GLOBAL POLICY Division: Title: GLOBAL QUALITY Page 1 of 12 Number GPOL-038 Revision 0 SUPPLY CHAIN SECURITY – TAMPERING AND COUNTERFEIT CONTROLS 1.0 Proposito 1.1 Para proporcionar la dirección y los requisitos de medidas y acciones tomadas para mantener la integridad de Apotex global de seguridad de la cadena de suministro. 1.1.1 1.1.2 1.1.3 Tener conciencia y visibilidad a las señales de alerta en el medio ambiente. Aplicar principios de gestión de riesgos. Para desarrollar programas específicos para abordar la adulteración, falsificación, robo y desvíos ilegales. Uncontroll ed Copy After: November 26, 2014 11:59:59 PM ET 2.0 Scope 2.1 2.2 2.3 2.4 Esta Política Global se aplica a la Apotex terminado de grupo de empresas productoras de formas de dosificación. También es aplicable a los afiliados de Apotex y los centros de distribución de Apotex. Esta Política Global puede usarse para la evaluación y supervisión de Apotex terceros organismos . Esta Política Global establece las pautas escritas describiendo los requisitos y consideraciones para implementar eficazmente las medidas de seguridad de cadena de suministro. La cadena de suministro es un proceso complejo que abarca muchas regiones geográficas e implica a numerosos partidos. Para garantizar la seguridad de la cadena de suministro, deben estar involucrados varios grupos funcionales (enfoque integral) sobre el ciclo vital de la cadena de suministro. 2.4.1 Este enfoque integrado puede facilitar la seguridad de la cadena de suministro al aumentar el sistema de calidad farmacéutica para prevenir y detectar la adulteración, falsificación, robo y desvío ilegal. Apotex puede ser capaz de mitigar ciertos riesgos asociados con materiales adulterados, falsificados, robados o desviados y entrar en la cadena de suministro mediante la aplicación de productos acabados apropiados principios y estrategias. 2.4.2 3.0 Owner Organizational Unit AGO-Global QA Policy and Systems. GPOL-038 rev. 0 Effective Date: 07/16/2013 Page incl. Approval: 1 of 13

- 2. GLOBAL POLICY Division: Title: GLOBAL QUALITY Page 2 of 12 Number GPOL-038 Revision 0 SUPPLY CHAIN SECURITY – TAMPERING AND COUNTERFEIT CONTROLS 4.0 General Training Requirements 4.1 Como mínimo, directores, directivos y gerentes de las siguientes áreas funcionales deben ser entrenados en cada sitio: - - calidad Manufacturing Operations.for the bold Research and Development. 123 Desarrollo de productos y operaciones técnicas. Engineering Services. red pencil Warehouse and Distribution. Red Pencil Sales and Marketing Ventas y Marketing. 1.2 libro. 1.2 book Uncontroll ed Copy After: November 26, 2014 11:59:59 PM ET - - - - - 4.2 5.0 Otro personal de la organización puede ser entrenados por la discreción de la administración del sitio. Associated Documents Document # QM GPOL-002 GPOL-007. GPOL-012 GPOL-014 GPOL-015 GPOL-023 GPOL-027 GPOL-029 GSOP-029-001 Document Title Apotex Quality Manual Management Controls – Governance, Management Notification, Management Review Manufacturing, Packaging, and Labelling Controls Material Controls. 1.2.3. Quality Risk Management. 1.2.3. Audit Program. 1.1.1.1. Warehouse Controls. 1.1.1.1 Supplier Qualification Program. 1.1.1.1 Distribution Controls. 1.1.11. Shipping Under Quarantine. 1.1.1.11. Relationship Governing Quality Manual.12 book Associated Global Policy Associated Global Policy Associated Global Policy Associated Global Policy Associated Global Policy Associated Global Policy Associated Global Policy Associated Global Policy Associated Global SOP. 1.2 GPOL-038 rev. 0 Effective Date: 07/16/2013 Page incl. Approval: 2 of 13

- 3. GLOBAL POLICY Division: Title: GLOBAL QUALITY Page 3 of 12 Number GPOL-038 Revision 0 SUPPLY CHAIN SECURITY – TAMPERING AND COUNTERFEIT CONTROLS 6.0 Definitions Term Adulteration.1.1.1.1. Apotex Cargo Theft. 1.1.11. Counterfeit. 1.1.11. Customer.1.1.1..1.1. Distributor/Broker. 1.1.1.1. Economically Motivated Adulteration.1.1.1. Environmental Scanning.1.1.1. First Tier Supplier.1.1.1.1 Definition The addition of a foreign or inferior substance or element to a drug, resulting in the drug not being w hat it is purported to be. Apotex group of companies producing finished dosage forms. Term also includes the affiliates and distribution centers. The theft of finished pharmaceuticals during transportation or w arehousing. The deliberate and fraudulent mislabelling of a drug w ith respect to identity and/or source. Where the first change in ow nership of a product takes place. A person or entity that sells, distributes, transports, and/or forw ards materials, but does not actually manufacture the material. The fraudulent, intentional substitution or addition of a substance in a product for the purpose of increasing the apparent value of the product or reducing the cost of its production, i.e. for economic gain. A process for review ing external information w hich may have an impact on selected targets. It involves the collection and analysis of information relevant to pre-defined targets. A first tier supplier is a supplier w ho directly invoices the organization for goods and/or services rendered directly by the first tier supplier to the organization as a customer. Diverting finished products from the intended supply chain, w here the intended supply chain refers to the law ful channels by w hich a pharmaceutical manufacturer transfers drug product to the first legal ow ner. A systematic process for the assessment, control, communication and review of risks to the quality of the pharmaceutical product throughout the product life-cycle. The systematic use of information to identify potential sources of harm (hazards) referring to the risk question or problem description. A second tier supplier is a supplier w ho invoices a first tier supplier for goods and/or services w hich w ill ultimately be part of the first tier supply organization. New information indicating the potential for economically motivated adulteration of a material or product, the use of counterfeit material, or the illegal diversion of legitimate product into unlaw ful channels. A particular vulnerable material or physical point in the supply chain w here adulteration, counterfeiting, or illegal diversion could occur. Risk management approaches should be used to help identify targets. A third tier supplier is a supplier w ho invoices a second tier supplier. Uncontroll ed Copy After: November 26, 2014 11:59:59 PM ET Illegal Diversion.1.1.11. Quality Risk Management (QRM) Risk Identification.1.1.1.1. Second Tier Supplier.1.1.1.1 Signal. Target..1.1.1.1. Third Tier Supplier.1.1.1. GPOL-038 rev. 0 Effective Date: 07/16/2013 Page incl. Approval: 3 of 13

- 4. GLOBAL POLICY Division: Title: GLOBAL QUALITY Page 4 of 12 Number GPOL-038 Revision 0 SUPPLY CHAIN SECURITY – TAMPERING AND COUNTERFEIT CONTROLS 7.0 Roles and Responsibilities. Role President & C.O.O. Responsibility - - - Review and Approve this Global Policy Proporcionar los recursos necesarios para la aplicación efectiva de esta Política Global. Garantizar una supervisión eficaz por la supervisión Ejecutiva Comité. Review and Approve this Global Policy Proporcionar supervisión de calidad de esta Política Global. Garantizar una supervisión eficaz por la supervisión Ejecutiva Comité. Review this Global Policy Ensure the Deployment / Implementation of this Global Policy at applicable Global Apotex sites Review this Global Policy Asegurar la implementación / ejecución de esta Política Global dentro de las funciones de desarrollo de producto. Review this Global Policy Asegurar la implementación / funciones de aplicación de esta Política Global en asuntos reguladores & científico. Review this Global Policy Ensure the Deployment / Implementation of this Global Policy w ithin R&D QA functions Review this Global Policy Ensure the Deployment / Implementation of this Global Policy at applicable Global Apotex sites Review this Global Policy Ensure the Deployment / Implementation of this Global Policy at applicable Global Apotex sites Uncontroll ed Copy After: November 26, 2014 11:59:59 PM ET VP, Corporate Quality & Compliance - - - EVP, Global Supply Operations - - - - - - - - - - - - Senior VP, Product Development Senior VP, Scientific & Regulatory Affairs Global Director, R&D QA. Global Director, External Quality Global Director, QA Audit GPOL-038 rev. 0 Effective Date: 07/16/2013 Page incl. Approval: 4 of 13

- 5. GLOBAL POLICY Division: Title: GLOBAL QUALITY Page 5 of 12 Number GPOL-038 Revision 0 SUPPLY CHAIN SECURITY – TAMPERING AND COUNTERFEIT CONTROLS Role Global Director, QA Manufacturing Sites Responsibility - - - - - - Review this Global Policy Ensure the Deployment / Implementation of this Global Policy at applicable Global Apotex sites Review this Global Policy Asegurar la implementación / ejecución de esta Política Global dentro de las funciones de cumplimiento Global. Review this Global Policy Supervisar la gestión, revisión, aprobación y despliegue / implementación de esta Política Global en sitios de Apotex mundial aplicables. Emitir, examinar y revisar esta Política Global según la orientación y regulación de la autoridad sanitaria actual. Distribuir esta Política Global.. Coordinar la implementación / ejecución de esta Política Global en sitios de Apotex mundial aplicables. Despliegue de la ayuda / implementación de esta Política Global en sitios de Apotex mundial aplicables. Coordinar actividades de seguridad de la cadena de suministro a través de equipos interdisciplinarios y departamentos en el sitio. Asegúrese de que procesos de seguridad de la cadena de suministro se definen, implementados y revisados, y que los recursos necesarios están disponibles en el sitio. Global Director, Quality Compliance Uncontroll ed Copy After: November 26, 2014 11:59:59 PM ET Global Director, QA Policy & Systems Global QA Policy & Systems Department - - - Site Leadership Team (Site Operations Head, Site Quality Head) - - - 8.0 Requerimientos Generales. 8.1 Entender el riesgo y la seguridad de la cadena de suministro. 8.1.1 Riesgo de adulteración (incluyendo económicamente motivado adulteración) 8.1.1.1 Adulteración puede ocurrir en muchas formas, incluyendo el producto que está contaminada, insegura o fabricados en condiciones de no cumplir con buenas prácticas de manufactura, o producto que no cumple con sus requisitos para la pureza y la fuerza, o no aprobadas para ser comercializada en el país. Apotex puede no ser capaz de prevenir completamente la falsificación a través de la Plaza del mercado global. El objetivo es definir los controles adecuados para minimizar el riesgo de los productos falsificados. 8.1.2 Riesgo de medicamentos falsificados. 8.1.2.1 GPOL-038 rev. 0 Effective Date: 07/16/2013 Page incl. Approval: 5 of 13

- 6. GLOBAL POLICY Division: Title: GLOBAL QUALITY Page 6 of 12 Number GPOL-038 Revision 0 SUPPLY CHAIN SECURITY – TAMPERING AND COUNTERFEIT CONTROLS 8.1.2.2. La falsificación puede aplicarse a productos tanto marcas y genéricos, y productos falsificados pueden incluir productos con ingredientes correctos o incorrectos, con ingredientes activos insuficientes o falta de ingredientes activos en conjunto, o con el empaquetado falso. Apotex puede realizar evaluaciones de riesgos para ayudar a identificar los productos y regiones presentan el mayor riesgo de falsificación. Esto puede usarse para ayudar a priorizar la asignación de recursos contra la falsificación. Desvío ilegal ocurre cuando un producto farmacéutico genuino es aprobado y destinado a la venta en un país, pero es luego interceptado ilegalmente y vendido en otro país. Estos esquemas se logran a menudo a través de declaraciones falsas o declaraciones. A veces, los reguladores de medicamentos en el segundo país no han aprobado el uso de la droga desviado. Desvío ilegal también puede ocurrir dentro de la misma área geográfica, o dentro del mismo país o ciudad. Este tipo consiste en desviar medicamentos con descuento de un pretendido grupo de consumidores a otro grupo de compra de medicamentos en un mercado abierto y no reglamentado. Prevenir y detectar la desviación ilegal no pueden lograrse mediante una única organización. Cada miembro de la cadena de suministro debe involucrarse en la prevención y detección del desvío ilegal desarrollar un enfoque integral. Gestión de riesgos de calidad (consulte GPOL-014) se utilizarán para conocer y comprender el producto de la droga y para evaluar la probabilidad de que se desvíen. Factores de riesgo pueden incluir productos de alto valor de drogas, medicamentos en corto la fuente, los productos con un alto potencial para el abuso de drogas o productos que son ampliamente utilizados de la droga. Entender la naturaleza de los riesgos de desviación ilegal es un elemento importante en el diseño de un programa contra la desviación proactivo. Entender los riesgos asociados con un producto robado es clave para la prevención. Gestión del riesgo de robo de carga es similar a las claves asociadas al desvío ilegal. ¿Cómo y dónde está siendo transportado un producto de drogas son factores claves de riesgo que debe ser entendidos. Comprensión de Apotex de delincuencia local, sistema educativo y las condiciones políticas y legales obstaculizan o incluso apoyando la falsificación, robo o desvío ilegal ayudará a identificar zonas geográficas de riesgo para la seguridad. Comprensión de estos riesgos puede utilizarse para aumentar el contenido de la auditoría, actividades experimentales y controles. Como parte de un enfoque de gestión de riesgos de calidad, las actividades de mitigación de riesgo pueden incluir la aplicación de medidas más estrictas para medicamentos con alto riesgo de falsificación, robo o desvío ilegal. 8.1.2.3 8.1.3. Riesgo de medicamentos desviados. 8.1.3.1. Uncontroll ed Copy After: November 26, 2014 11:59:59 PM ET 8.1.3.2 8.1.3.3 8.1.4. Riesgo de robo de carga. 8.1.4.1. 8.1.4.2 8.1.5. Identificación de riesgos de factores geográficos. 8.1.5.1. 8.1.5.2 8.1.6. Clasificación de riesgo y filtrado para distinguir las prácticas. 8.1.6.1. GPOL-038 rev. 0 Effective Date: 07/16/2013 Page incl. Approval: 6 of 13

- 7. GLOBAL POLICY Division: Title: GLOBAL QUALITY Page 7 of 12 Number GPOL-038 Revision 0 SUPPLY CHAIN SECURITY – TAMPERING AND COUNTERFEIT CONTROLS 8.1.6.2 La evaluación del riesgo puede ser revisada para determinar si Apotex mantendrá operaciones específicas para ayudar a evitar la falsificación, desvío ilegal o robo. Buenas análisis son esenciales para garantizar la seguridad de los materiales suministrados y detectar la adulteración, intencional o no intencional. Apotex puede realizar una evaluación de riesgos de calidad de los procesos de fabricación e identificar cualquier material potencialmente vulnerables.. Se entenderá las limitaciones de los métodos actuales, y donde se pueden desarrollar métodos de prueba apropiados, físicas, químicas o biológicas para identificar el material. El fabricante es responsable por la seguridad de todos los materiales utilizados en la fabricación y la utilización de los análisis más apropiado.. 8.1.7. Risk Mitigation – Analytical/Characterization 8.1.7.1. 8.1.7.2 8.1.7.3 Uncontroll ed Copy After: November 26, 2014 11:59:59 PM ET 8.2. A manual, computerized, and/or enterprise-w ide inventory management system must be in place w ith supervision from qualified personnel. 9.0 Quality Risk Management (QRM) 9.1 The QRM shall be used to develop a risk-based approach to supply chain security. This includes assessing risks, developing controls, conducting risk review s, and communicating appropriately. Refer to GPOL-014. As part of the risk management process, processes shall be established to assure risks are communicated throughout the organization. Refer to GPOL-002. 9.2 10.0 Manufacturing, Packaging, and Labeling Controls Program 10.1 In the context of a drug product, adulteration results in a drug w hich is not w hat it is purported to be. Adulteration can be accidental or intentional. Additional controls are required to reduce the risk of adulteration w hen there are complex supply chains w hich involve significant outsourcing of manufacturing and distribution. 10.1.1 Refer to Section 8.0 (General Requirements) in considering potential and current control measures in the manufacturing, packaging, and labelling of the drug products, w ith a look at potential advancement in technology. 10.2 Further consideration shall be given to assessing established controls for packaging and labeling systems and controls on returned and salvaged products. Procedures shall be established w hich describe the destruction of packaging and labeling materials. GPOL-038 rev. 0 Effective Date: 07/16/2013 Page incl. Approval: 7 of 13

- 8. GLOBAL POLICY Division: Title: GLOBAL QUALITY Page 8 of 12 Number GPOL-038 Revision 0 SUPPLY CHAIN SECURITY – TAMPERING AND COUNTERFEIT CONTROLS 10.3 Destruction of rejected materials should be accounted for and proof of the destruction shall be obtained and documented. Accountability for the destruction of labels and packaging materials, and destruction of returned products, shall extend to the management of third party suppliers, contract manufacturers, and logistics service providers. Also refer to GPOL-007 (Manufacturing, Packaging, and Labelling Controls) and GPOL-023 (Warehouse Controls). 10.4 Uncontroll ed Copy After: November 26, 2014 11:59:59 PM ET 11.0 Material Controls 11.1 11.2 11.3 11.4 11.5 11.6 Both customers and inter-company receivers of a drug product shall be particularly careful to monitor for the intrusion of diverted product. Seal numbers taken off arriving trucks shall be checked against the seal numbers recorded on shipping papers. The number of boxes received shall be the same as the number of boxes recorded on the shipping papers and invoices as shipped. Boxes shall be examined for evidence of original closures (e.g. tape w hich may have been replaced). Boxes w ith visible differences (e.g. different shade or size of carton) shall be examined carefully. Also refer to GPOL-012 (Material Controls). 12.0 Warehouse Controls and Distribution Controls 12.1 Detection processes shall be consistent w ith the risk of illegal diversions of given drug product. Monitoring of packaging, packing, and shipping departments shall be review ed to determine if the use of surveillance equipment is w arranted. 12.1.1 12.1.2 12.1.3 Workers in these areas should be aw are of the area surveillance as a deterrent. Periodic job rotation, to include security personnel, should be considered. The signal detection process shall involve: - - - Defining targets for enhanced, ongoing scrutiny Applying environmental scanning to those targets (e.g. review ing external information that may have an impact on the targets) Determining the relevance of the results of environmental scans GPOL-038 rev. 0 Effective Date: 07/16/2013 Page incl. Approval: 8 of 13

- 9. GLOBAL POLICY Division: Title: GLOBAL QUALITY Page 9 of 12 Number GPOL-038 Revision 0 SUPPLY CHAIN SECURITY – TAMPERING AND COUNTERFEIT CONTROLS 12.2 The identity of the person w ho packs from bulk and w ho packs for shipping shall be recorded. Claims for shortages shall be checked for correlation to these w orkers. Product stolen by w orkers is considered diverted product. Processes shall be in place to verify the physical integrity of the container structure prior to loading, including the reliability of the locking mechanisms of the doors. Numbered single-use seals shall be used and recorded on shipping papers w hen the entire conveyance is used for one shipment. Only designated employees shall distribute seals for integrity purposes. There shall be procedures in place for the control and reconciliation of seals, describing how to properly affix seals onto loaded containers and how to recognize and report compromised seals or seal discrepancies. Arriving cargo shall be reconciled against information on the cargo manifest. The cargo shall be accurately described, and the w eights, labels, marks, and piece count indicated and verified. Departing cargo shall be verified against purchase or delivery orders. Drivers delivering or receiving cargo shall be positively identified before cargo is received or released. Customers shall be directed to return all unsold product to the manufacturer for evaluation. Returned materials shall be dispositioned in accordance to approved w ritten procedures. If the customer is in another country w here the return is not feasible, special care shall be taken to arrange for destruction by a trusted third party organization. 12.3 12.4 Uncontroll ed Copy After: November 26, 2014 11:59:59 PM ET 12.5 12.6 12.7 12.8 12.9 12.10 Returned product shall be analyzed to determine authenticity. If the product is not authentic, Apotex shall investigate w here the potentially diverted or counterfeit product entered the supply chain. 12.11 Also refer to GPOL-029 (Distribution Controls), GPOL-023 (Warehouse Controls), and GSOP-029-001 (Shipping Under Quarantine). 13.0 Supplier Quality Management and Audit Program 13.1 The elements of the Supplier Quality Management Program shall be integrated to allow appropriate modes of controls to be implemented. When these controls are integrated, there is a higher level of assurance over suppliers and outsourced activities. Refer to GPOL-027 (Supplier Qualification Program) and GPOL-015 (Audit Program). Quality risk management principles (risk-based approach) utilized in the process of assessing and selecting a potential supplier shall be applied appropriately to the material being supplied. Communication of Apotex’s requirements and standards are to be clearly communicated at the start of the assessment/selection process. 13.2 13.3 GPOL-038 rev. 0 Effective Date: 07/16/2013 Page incl. Approval: 9 of 13

- 10. GLOBAL POLICY Division: Title: GLOBAL QUALITY Page 10 of 12 Number GPOL-038 Revision 0 SUPPLY CHAIN SECURITY – TAMPERING AND COUNTERFEIT CONTROLS 13.4 A multi-disciplinary approach is highly recommended in the supplier selection process. Including functional groups such as Regulatory, Quality, Safety, Health, and Environmental (SHE), Technical, Security, and Procurement w ill frequently lead to a more balanced assessment of potential suppliers. Similarly, having a cross functional team involved in the audit (e.g. a new supplier) is part of the risk-based approach. The full extent of the supply chain shall be know n and documented in a manner providing the necessary visibility. Apotex shall have current understanding of information from second and third tier suppliers on the logistics of supply chain from the origin of procured materials through to receipt at the manufacturing location. Apotex shall also have current information from the site of manufacture to the next legal ow ner or buyer of the product. Apotex may not alw ays receive material directly from the original manufacturer, but rather through a distributor/broker. In the assessment of a distributor/broker, it is important to understand expectations w ith regard to supervision of the original manufacturer. Once the selection process is complete, w ritten agreements for quality activities shall be developed w ith the supplier of choice. Quality/Technical Agreements, Supply Agreements, contracts, or comparable w ritten agreements shall clearly communicate and document Apotex’s requirements and standards, and shall specify the need for the supplier to conform to the agreements. 13.7.1 Minimum requirements shall be established around notification of changes, notification of significant deviations, notification of any regulatory inspections, a provision for documentation review , and a provision for on-site audits. 13.5 Uncontroll ed Copy After: November 26, 2014 11:59:59 PM ET 13.6 13.7 13.8 13.9 Supplier performance shall be monitored and review ed on a regular basis. A defined audit program shall be established w ith risk-based criteria for frequency and duration of audits. 14.0 Logistics and Transportation Service Providers 14.1 The management of logistics and transportation service providers is analogous to Supplier Quality Management in that the process for the assessment, selection, monitoring, and review are similar; how ever, the focus includes more elements of security features. Controls must be in place to assure logistic service providers do not become an avenue for illegal diversion or introduction of counterfeit products into the supply chain. Specific attention shall be applied to ensure pertinent security measures are in place and adhered to at the logistics and/or transportation service provider. As part of the selection and assessment, there shall be evidence of financial soundness, capability of meeting contractual security requirements, and the ability to identify and correct security deficiencies. 14.2 14.3 14.4 GPOL-038 rev. 0 Effective Date: 07/16/2013 Page incl. Approval: 10 of 13

- 11. GLOBAL POLICY Division: Title: GLOBAL QUALITY Page 11 of 12 Number GPOL-038 Revision 0 SUPPLY CHAIN SECURITY – TAMPERING AND COUNTERFEIT CONTROLS 14.5 Background information, including a history of claims, the types of commodities handled, and the geographical areas served shall be provided by the service provider and used as part of the assessment and selection process. Hiring practices of the provider shall be review ed. A review of the sales volume and relevant permits of the provider shall be review ed in comparison to the size of the operation and authorization to handle pharmaceutical products, w here such permits are required. Review of physical premises, hiring practices, and access controls must be satisfactory in meeting security measures. 14.6 14.7 Uncontroll ed Copy After: November 26, 2014 11:59:59 PM ET 15.0 External References Document Title Health Products and Food Branch Inspectorate (HPFBI), Good Manufacturing Practices (GMP), Guidelines - 2009 Edition, Version 2, GUI-0001, March 4, 2011 (w ww.hc-sc.gc.ca) Health Products and Food Branch Inspectorate (HPFBI), Policy on Counterfeit Health Products, POL-0048, May 14, 2010 (w ww.hc-sc.gc.ca) Food And Drug Administration, Inspections, Compliance, Enforcement, and Criminal Investigations – Inspections – Investigations Operations Manual, Sub-chapter 8.8 – Counterfeiting/Tampering (w ww.fda.gov) EudraLex, The Rules Governing Medicinal Products in the European Union, EU Guidelines for Good Manufacturing Practice for Medicinal Products for Human and Veterinary Use (Volume 4), 2008, Annex 20: Quality Risk Management (w ww.ec.europa.eu) ICH Harmonised Tripartite Guideline, Quality Risk Management Q9, Current Step 4 version, November 9, 2005 (w ww.ich.org) Pharmaceutical Security Institute Counterfeit Situation w ww.psi-inc.org World Health Organization General information on counterfeit medicines WHO Technical Report Series, No. 902, 2002, Annex 9, Guidelines on Packaging for Pharmaceutical Products (w ww.who.int) WHO Guidance Reference Type Health Canada Guidance Health Canada Policy US FDA Manual European Commission Guidance (EMEA,MHRA) International Conference on Harmonisation (ICH) Guidance PSI Guidance GPOL-038 rev. 0 Effective Date: 07/16/2013 Page incl. Approval: 11 of 13

- 12. GLOBAL POLICY Division: Title: GLOBAL QUALITY Page 12 of 12 Number GPOL-038 Revision 0 SUPPLY CHAIN SECURITY – TAMPERING AND COUNTERFEIT CONTROLS 16.0 Revision History Revision Effective No.Date 0 Current Change Control No. 46061 Description / Reason for Change New Global Policy “Supply Chain Security – Tampering and Counterfeit Controls”. Author of Revision Elaine Leong, Manager, QA SOD Uncontroll ed Copy After: November 26, 2014 11:59:59 PM ET GPOL-038 rev. 0 Effective Date: 07/16/2013 Page incl. Approval: 12 of 13

- 13. APPROVALS AND SIGNATURES UserName: Jeremy Desai (apotexjdesai) Title: President & C.O.O, Apotex Inc. Date: Thursday, 23 May 2013, 12:23 PM Eastern Time Meaning: Approval ================================================ Uncontroll ed Copy After: November 26, 2014 11:59:59 PM ET UserName: Jila Breeze (apotexjbreeze) Title: VP, Corporate Quality & Compliance Date: Tuesday, 28 May 2013, 08:51 AM Eastern Time Meaning: QA Approval ================================================ GPOL-038 rev. 0 Effective Date: 07/16/2013 Page incl. Approval: 13 of 13