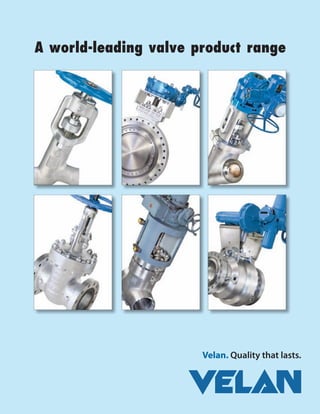

A world leading valve product range

- 1. A world-leading valve product range Velan. Quality that lasts.

- 2. A world leader in valve design, engineering solutions, and manufacturing Velan holds all major industry certifications, including ASME VELAn AT A GLAnCE Section III, ISO 9001:2000, PED, History and API 6D. Many prominent • Founded in 1950 companies have established Sales partnerships or global supply • Over $400 million agreements with Velan. People • Over 1,800 employees A global manufacturing Global network leader • 13 production facilities • 5 plants in North America Velan uses the latest automation • 4 plants in Europe technology, including CNC ma- • 4 plants in Asia chines and many special-purpose • 4 stocking and distribution transfer machines, enhanced by centers proprietary production tech- • Hundreds of distributors niques. Thanks to a wide range worldwide of equipment, we can efficiently • Service shops worldwide handle highly customized orders Product line as well as large production runs. A world-leading range of cast and forged steel gate, globe, Velan employs over 1,800 profes- check, ball, triple-offset, sionals, the majority of whom knife gate, severe service are located in North America. valves and steam traps International production centers across all major industrial are complemented by a global applications sales and distribution network, Quality A large Torqseal ™triple-offset valve used for crude oil service offering personal customer All major approvals in the Dalian Seaport (China). service and quick access to stock • ISO 9001 (since 1991) worldwide. Because customer • ASME N stamp for nuclear requirements for immediate quality (since 1970) Leading the way... Engineered solutions deliveries have escalated in the • API 6D last few years, Velan has opened • Total Process Improvement Velan is one of the world’s Velan’s Engineering Group has a number of quick-ship ware- Program including Lean largest manufacturers of indus- vast experience, sophisticated houses in North America Manufacturing, Six Sigma trial steel valves, recognized as software, and testing tools that to supplement the inventories Engineering a leader in quality and innova- enable us to find solutions to any of our stocking distributors. Leader in valve design with tion. Founded by A.K. Velan in customer challenge. many first-to-market 1950, our company leverages innovations: advanced engineering capabili- Whether it is for valves to handle Total quality commitment • Extensive engineering, ties and innovation to continu- liquid helium at -458°F (-272°C) R&D, cycle test facilities, Velan is totally committed to and stress analysis ously expand our offering of in the world’s largest particle offering products and service that • Proven ability to satisfy industrial valves. accelerator at CERN, Geneva; exceed customer expectations. special project requirements four-way switch coker ball All Velan valves are designed and Today, Velan gate, globe, check, valves to handle one of the • Field Engineering Services manufactured with an emphasis ball, triple-offset, knife gate, refining industry’s toughest on low emissions, safety, simple Production capabilities and engineered severe service services; or valves for main Leader in automated maintenance, ease of operation, valves are installed throughout steam isolation service in an production: and above all, long, and reliable the world, handling diverse operating nuclear power plant, • CNC and multi-station service life. In fact, several years applications in cogeneration, Velan has been selected by transfer machines ago when a leading North Ameri- fossil, nuclear power, oil and most of the world’s leading can repair shop did an analysis Velan value gas, refining and petrochemicals, engineering construction firms • Strong management team, on the reliability and repairabil- chemicals and pharmaceutical, and industrial end users. A long- stable company ity of commodity valves, Velan pulp and paper, LNG and cryo- standing commitment to quality Products proven to offer: finished first. Whether we are genics, marine, mining, water has kept Velan at the forefront • Low emissions manufacturing commodity valves and wastewater, and HVAC of industry standards. • Easy maintenance or specialty valves, we deliver industries. • Long and reliable service excellent long-term value to our • Low TCO customers. • Quality that lasts 2 Velan reserves the right to change this information without notice. © 2009 Velan Inc. All rights reserved.

- 3. Serving the industrial world’s toughest applications Performance under pressure PrimAry indusTriEs All over the world, Velan valves are used by leading industrial sErVEd companies to help keep their • Fossil, nuclear, and operating facilities running cogeneration power smoothly. In fact, Velan valves • Oil and gas have a long history of proving themselves in many of the • Refining and industrial world’s toughest petrochemicals applications. • Chemicals and pharmaceutical Our valves have provided long, trouble-free service life in such • LNG and cryogenics tough applications as hydro- crackers, cokers, LNG terminals, • Marine nuclear aircraft carriers and • Mining submarines, digester capping, green liquor, iron pellets, boiler • HVAC blowdown, fly ash, ethylene, jet • Water and wastewater fuel, slurries, and countless other applications where there is no • Pulp and paper substitute for experience and proven performance. Head Office & Plant 5 Plant Plant Global service with strong local presence Velan is a true global manufac- MONTREAL, CANADA LYON, FRANCE MENNECY, FRANCE turing leader. What’s more, our global presence goes far beyond Plant 1 Plant our manufacturing facilities. GLobAL nETwork Velan’s wide range of valves are • 13 manufacturing plants sold through an extensive net- worldwide work of distribution companies. MONTREAL, CANADA • 4 stocking distribution LISBON, PORTUGAL centers Velan valves are available Plant 2 & 7 Plant from hundreds of distributors • Hundreds of distributors in worldwide, guaranteeing that over 400 locations one of our Velan representatives • Service shops worldwide is always nearby and ready to MONTREAL, CANADA ANSAN CITY, SOUTH KOREA help. Our distributors are further Plant 3 Plant Plant supported by our North American and European distribution centers. Velan’s large inventories and premier sales network have helped us become a leader in WILLISTON, VT, USA LEICESTER, UK ANSAN CITY, SOUTH KOREA supplying maintenance, repair, Plant 4 & 6 Distribution Center Distribution Center Plant and overhaul (MRO) contracts to many of the world’s largest industrial companies. GRANBY, CANADA WILLICH, GERMANY TAICHUNG, TAIWAN Distribution Center Distribution Center Plant MARRIETTA, GA, USA BENICIA, CA, USA SUZHOU, CHINA Velan reserves the right to change this information without notice. © 2009 Velan Inc. All rights reserved. 3

- 4. An extensive product line for all your industrial valve needs A one-stop valve shop VALVE TYPE SIZE RANGE Velan offers one of the most check, piston, tilting disc comprehensive valve product ball, resilient-seated y-pattern (inclined) ball, metal-seated lines available from any check, dual-plate manufacturer. From the most check, swing parallel slide globe (stop) triple-offset steam trap common application to the most butterfly severe, Velan has a solution. control 1/4 - 2” needle 4 - 24” angle 2 - 4” + 26” knife gate We produce gate, globe, check, PRODUCT LINE ball, triple-offset, knife gate, GATE, GLOBE & CHECK Pressure seal and bolted bonnet valves and engineered severe service API 600* cast steel valves valves and steam traps in sizes API 603* stainless steel valves up to 64” (1600 mm) and for API 602* small forged valves services up to ASME Class 4500. Y-pattern valves Stainless steel knife gate valves Our products incorporate many Dual-plate check valves unique design features for low fugitive emissions, simple Memoryseal ball valves ™ in-line maintenance, and long API 6D and 6A ball valves QUARTER-TURN service life. Securaseal metal-seated ball valves ® Power ball valves Coker ball valves built to order General purpose ball valves Torqseal triple-offset valves ™ Our valves are available with Velflex cryogenic butterfly valves ™ a large selection of steel body materials, trims, options and Bellows seal valves OTHER accessories. With options such Cryogenic control valves as bypasses and equalizers Steam traps to special trims for HF acid or * The API designation defines the product design basis even though not all the valves are covered in the referenced API specification. NACE service, Velan can These valves are also used in non-API service. provide valves built to your needs — often directly from our sales network’s extensive stock. Delivering value through performance All Velan valves are available with actuation packages according to your needs. Low total cost of ownership This includes electric, hydraulic, When you take into account all independent studies, and, most and pneumatic actuation with the factors involved in owning importantly, in working field a complete range of controls a valve — including installation, conditions. and sensors. service, and maintenance — the total cost of ownership of a valve Apart from field-tested and can be several times the initial proven valves, we also offer Customer support purchase price. supplier-integrated engineer- Velan’s engineering team has a ing, value-added services, and long history of working with Velan valves are designed and all the other advantages you customers to solve their valve manufactured to save you money would expect from a world-class application problems. Our team by lowering maintenance costs and organization. of application engineers offer fugitive emissions and increasing professional advice and Right off the shelf, Velan valves service life and the chance that a Any way you look at it, Velan expertise enabling them to are backed by the most stringent valve can be repaired rather than offers exceptional performance select the best valve for any fugitive emissions guarantees in replaced. We offer value unparal- and value. environment. the industry. leled in the industry. The performance of our valves has been proven over and over again in thousands of qualification tests, 4 Velan reserves the right to change this information without notice. © 2009 Velan Inc. All rights reserved.

- 5. ASME CLASS TEMPERATURE MATERIALS CERTIFICATIONS INDUSTRY Refining and petrochem Water and wastewater Oil and gas upstream LNG and cryogenics nickel alloy steels Marine and navy Pulp and paper stainless steel carbon steel alloy steel fire tested cryogenic Chemical TA LUFT ASME N Mining API 6D Power HVAC 1500 2500 4500 high PED low 150 300 600 900 N N 150 psi max. Inherently fire safe Total quality commitment Quality is our first priority Velan has introduced many Automated production innovative technologies to the How does Velan design and market, many of them simplify- Velan has long been a leader in manufacture valves that ing maintenance and increasing automated production of world- Our aim is to offer offer superior performance, service life. Keen attention to class valves. Our network of products and services reliability, and service life? We design detail and actual field CNC machines employing Tool that not only meet are committed to total quality feedback help us constantly Data Management software but also clearly exceed in all we do. Since our company and rigorous semi-automated the expectations of our improve our products and was founded, our entire testing ensure our valves have customers. maximize performance. philosophy has been focused the tightest tolerance and the Through training, teamwork, on quality. Our comprehensive greatest level of consistency and performance, Quality Assurance System is strategic procurement and reliability. our employees strive geared towards continuous to achieve improvement, process quality, Velan runs a strategic procure- continuous improvement and stringent compliance to ment program to help ensure Production testing of all processes. worldwide standards (e.g., final product quality. Velan’s ASME section III, PED, TUV, ISO Casting Quality Program brings Every Velan valve is subjected to Our goal is total quality 9001:2000). together resident engineers at hydrostatic testing before leav- and on-time delivery; foundries, at-foundry statisti- ing the factory to help ensure our method is cal analysis programs, and problems won’t arise in the field. total commitment. design Magmasoft ® pour simulation Production tests are part of our Velan’s Engineering Group software, to help us achieve an strict QC Program, developed A.K. Velan performs FEA and qualification extremely low shell-leakage re- over many years as a leading Founder & CEO testing to validate designs. jection rate of less than 0.05%. supplier of nuclear valves. Velan reserves the right to change this information without notice. © 2009 Velan Inc. All rights reserved. 5

- 6. Gate, globe, and check valves PrEssurE sEAL And APi 600* APi 603* APi 602* boLTEd bonnET VALVEs CAsT sTEEL VALVEs sTAinLEss sTEEL VALVEs smALL ForGEd VALVEs Forged pressure seal and large API 600* Cast steel gate, globe, API 603* Corrosion-resistant Comprehensive range of small bolted bonnet gate, globe, and and check valves for a broad stainless steel gate, globe, forged gate, globe, check, angle, check valves for high pressure range of applications and swing check valves and bellows seal valves and high temperature service Sizes: 2–24” (50–600 mm) Sizes: 2–64” (50–1600 mm) Sizes: ¼ –24” (8–600 mm) Sizes: ¼ – 4” (8–100 mm) ASME classes: 150–4500 ASME classes: 150–1500 ASME classes: 150–300, 800 ASME classes: 150–4500 • One-piece forged bodies for • World’s largest manufacturer • Gate, globe (stop and needle), • Bolted and welded bonnet superior strength and quality of cast steel gate, globe, and and check (swing) valve types body styles • Live-loaded bonnet as a check valves • Available in cast stainless steel • Gate, globe (angle, needle, standard feature • Bubble-tight shut-off of gate • Available for cryogenic and and stop), and check (ball, • Graphite pressure seal gasket valves up to 12” (300 mm) NACE (sour gas) services piston, and swing) • Gate, globe (needle and stop), valve types • Machined body guides and a robust torque arm assembly and check (swing and piston) • Available in forged carbon, valve types stainless, alloy (including F91), • Gate (flexible wedge and and nickel alloy steels parallel slide), globe (angle, • Available in cast carbon, needle and stop), and check stainless, alloy, and nickel • Standard low fugitive emission (piston, swing, and tilting disc) alloy steels packing and also available with valve types • Standard low fugitive emission bellows seal for zero emission packing and also available with services • Optional cast product offering bellows seal for zero emission • Available for block and bleed, • Available in carbon, stainless, services cryogenic, HF acid, NACE alloy (including F91), and (sour gas), and nuclear nickel alloy steels • Available for block and bleed, cryogenic, HF acid, NACE services • Available for catalytic (sour gas), and nuclear reforming, NACE (sour gas) services and nuclear services Product catalog: VEL-PS Product catalog: VEL-CSV Product catalog: VEL-API 603 Product catalog: VEL-SF * The API designation defines the product design basis even though not all the valves are covered in the referenced API specification. These valves are also used in non-API service. 6 Velan reserves the right to change this information without notice. © 2009 Velan Inc. All rights reserved.

- 7. y-PATTErn sTAinLEss sTEEL ProQuiP ® VALVEs kniFE GATE VALVEs duAL-PLATE ChECk VALVEs Forged, one-piece high pressure Standard and bolted bonnet, all Retainerless dual-plate check valves inclined y-pattern valves stainless steel knife gate valves for a broad range of applications Sizes: ½ – 4” (15 –100 mm) Sizes: 2 – 36” (50 – 900 mm) Sizes: 2–60” (50–1500 mm) ASME classes: 1690 – 4500 ASME flange: up to 150 ASME classes: 150–2500 API 6A classes: 2000–5000 • One-piece forging with • All stainless steel design • Lightweight integral body-bonnet design • 0-14ph packing standard • Resilient and metal seats • Fully guided, non-spinning, stellite disc • Locking device on standard • Retainerless design for fugitive knife gate valve emissions control • Non-rotating stem • In-line repairable • Environmentally friendly • Wafer, lug, double flange, bi-directional bolted bonnet hub-end and butt-weld end • Globe (needle and stop) and and standard body styles body styles check (piston) valve types • Available in forged carbon • Resilient and metal seats • Available in carbon, stainless, steel, stainless, alloy • Available in cast stainless alloy, titanium, nickel-alum- (including F91), and nickel steel bronze, and nickel alloy steels alloy steels • Available for cryogenic and • Available with bellows seal NACE (sour gas) services • Available for nuclear and NACE (sour gas) services Product catalogs: VEL-BG Product catalog: VEL-KGV Product catalog: VEL-PQCV VEL-XBG Velan reserves the right to change this information without notice. © 2009 Velan Inc. All rights reserved. 7

- 8. Quarter-turn valves mEmorysEAL sECurAsEAL PowEr bALL APi 6d And 6A ™ ™ bALL VALVEs mETAL-sEATEd bALL VALVEs bALL VALVEs VALVEs Resilient-seated ball valves with Severe service metal-seated ball Forged, one-piece metal-seated API 6D and 6A trunnion-mounted value-added technical features valves for high temperature, ball valves for high temperature and floating ball valves for for superior performance abrasive, and corrosive applications and high pressure applications pipelines and offshore oil platforms Sizes: ¼ –24” (8 – 600 mm) Sizes: ½ – 24” (15 – 600 mm) Sizes: ½–4” (15–100 mm) Sizes: 1–64” (25–1600 mm) ASME classes: 150 – 600 ASME classes: 150 – 4500 ASME classes: 900–4500 Pressure Classes: WOG: up to 2000 Temp: up to 1500°F (816°C) 6D: ASME 150–2500 6A: API 2000–15000 • Memoryseal ™ in-tension • Shut-off to FCI 70-2 class 6 • Forged, one-piece body flexible seat design • Advanced trim coating • HVOF coated, inconel ball • Bolted body, top-entry, • E-20 low emission packing technology and downstream seat and welded body types arrangement • Low emission stem seal with • Blowout proof stem • Resilient or metal-seats • Fire tested API 607/ISO 10497 live-loaded packing as a • Fire tested (API 607 rev. 4, • Tested to zero-leakage BS 6755 - Part II and • End-entry, one-piece, standard feature • Standard stem/packing API 6FA) split-body, top-entry, unibody, • Cast and forged bodies live-loading • Available in carbon, and three-piece body styles • Available in carbon, stainless, stainless, alloy, and (three-piece design includes • Integral ISO mounting pad alloy, duplex, titanium, and for easy automation nickel alloy steels a flexible lip seat) nickel alloy steels • Available for cryogenic, • Available in carbon, stainless, • Available for aggressive slur- NACE (sour gas), subsea, alloy, and nickel alloy steels ries, batch digester capping, and underground services • Available for block and bleed, block and bleed, NACE (sour chlorine, cryogenic, NACE gas), nuclear, and oxygen (sour gas), nuclear, oxygen, service throttling, and vacuum services Product catalog: VEL-BV Product catalog: VEL-MS Product catalog: VEL-PBV Product Catalog: VEL-BV6D 8 Velan reserves the right to change this information without notice. © 2009 Velan Inc. All rights reserved.

- 9. CokEr bALL VALVEs VALVAC TorQsEAL VELFLEx ™ ™ GEnErAL PurPosE TriPLE-oFFsET CryoGEniC buTTErFLy bALL VALVEs VALVEs VALVEs World leader in coker ball valves Resilient-seated ball valves for Bi-directional, zero-leakage, High performance cryogenic and high temperature slurry general use and commodity triple-offset, metal-seated valves metal-saeated butterfly valves applications applications Sizes: 6 – 36” (150 – 900 mm) Sizes: ¼ – 2” (8 – 50 mm) Sizes: 3–80” (80–2000 mm) Sizes: 6–48” (150–1200 mm) ASME classes: 150 – 900 WOG: 600 – 2000 ASME classes: 150–900 ASME classes: 150–300 Temp: -425 to 1200°F Temp: down to -420°F (-252°C) (-254 to 650°C) • 6–18” switch valves, • End-entry, one-piece, and • Butt-weld end or flanged types • ASME classes 300–900 three-piece body styles • Zero-leakage to API 598 • Side-entry design offers easy for delayed cokers • Available in carbon and resilient-seat standard in-line maintenance • 6–36” isolation valves, stainless steel • Bi-directional shutoff • Bi-directional shutoff • ASME classes 150–900 for • Fire tested to API 607/ISO 10497 • Zero-leakage to API 598 delayed cokers • Available in lug or wafer per • Metallic seal • Complete automation pack- API 609, flanged per ISO 5752 (Velflex™ technology) ages including valve interlocks or ASME B16.10, and butt weld per ASME B16.10 body patterns • Fire tested (API 607 rev. 4, through PLC or DCS API 6FA and BS 6755 - Part II) • Two wire loop controls and • Available in carbon, stainless, diagnostic packages alloy, duplex, titanium, and nickel alloy steels • Available for cryogenic, NACE (sour gas), nuclear service, and vacuum service Product catalogs: VEL-BF Product catalog: VEL-CBV Product catalog: VEL-GPBV Product Catalog: SAS-CFLEX SAS-CTORQ Velan reserves the right to change this information without notice. © 2009 Velan Inc. All rights reserved. 9

- 10. Special applications bELLows sEAL VALVEs CryoGEniC ConTroL sTEAm TrAPs VALVEs The original hermetically sealed Severe service control valves for An extensive range of traps bellows seal valves for absolute extreme temperature applications for steam and air lines zero-leakage service Sizes: ½ – 12” (15 – 300 mm) Sizes: ¼ –16” (8 – 400 mm) Sizes: ¼–3” (8–80 mm) ASME classes: 150 –1500 ASME classes: 150 –2500 Temp: up to 1,100°F (593°C) Temp: down to -457°F (-272°C) Pressure: up to 4000 psi (276 bar) Cv: 0.01 to 1800 Capacities: 160,000 lb/hr (72,575 kg/hr) • Multi-ply stainless steel, • Resilient stainless steel design • Available in Piping King inconel and hastelloy • Linear or equal percentage arrangements bellows for long service life flow characteristics • Cage unit design for easy • Gate, globe (angle, needle, • Top-entry for easy maintenance in-line repair and stop), and control valves • Float bimetallic, hermetically • Anti-cavitation,and low dB • Available in carbon, stainless, design for critical applications sealed, piston-operated, alloy, and nickel alloy steels space-heating, and • Available for lethal, NACE thermodynamic types (sour gas), nuclear, and • Optional blowdown valve, vacuum service temperature controller, thermometer, and vacuum breaker available Product catalog: VEL-BS Product catalog: SAS-CCON Product catalog: VEL-ST 10 Velan reserves the right to change this information without notice. © 2009 Velan Inc. All rights reserved.

- 11. Engineered solutions After market A wide range of actuation AuTomATion Velan After Market offers a options complete range of Velan OEM CAPAbiLiTiEs Velan and our distribution After Market services, including • Electric, hydraulic, and Velan Field Engineering Services, channels offer OEM actuators that meet the most demanding pneumatic actuation Velan OEM Spare Part and tool support, and Velan maintenance on/off and control applications. • Pre-installation of switches, training courses. Velan interviews and audits our positioners, thrust and distributors before appointing torque sensors, signal Velan Field Engineering them as authorized actuator- Services offers customers conditioners mounting shops. We carry out in-line service, maintenance, • Integral control actuation and product support on all extensive qualification of the actuators in-house. and two-wire control our valve products. Our team of engineers and technicians • OEM actuators through are equipped with Velan OEM Velan offers a wide range of Velan stocking distribution Stress calculations are done using tools, lapping equipment and products to address each or other actuators of your 3D Finite Element Analysis (FEA) Velan OEM parts. With over customer application, from choice software, like ANSYS and Pro/Me- 50 years of valve-servicing multi-turn electric actuators chanica, with 3D models developed experience to nuclear and on rising-stem valves to scotch- • Overides, limit stops, and in Pro-Engineer. thermal power stations, refining yoke or double-opposed piston most standard accessories and petrochemical plants, navy actuators on rotary valves. fleets, and many other industries, Engineering expertise Velan offers true OEM service. Whatever your Furthermore, Velan has a net- Over the years, Velan has work of authorized service shops industrial valve brought together a strong team across the globe, ensuring we needs, we can of professional engineers with can meet your maintenance and meet them extensive experience in critical service requirements whatever with the highest applications. Using advanced your location. We also have quality products. software applications including a complete library of Velan Finite Element Analysis (FEA), Maintenance Manuals. Computational Fluid Dynamics Velan OEM Spare Part and tool (CFD), and 3D Solid-Modeling, support offers support on all Velan’s engineers design supe- Velan products. You are ensured rior quality valves that meet the of Velan OEM parts built to the most demanding performance same configuration as originally requirements. Our R&D facilities, supplied. We can advise on equipped with steam boilers, recommended spare parts and superheaters, flow loops, and on new projects we can advise cryogenic test stands, enable Spare Part Interchangeability Reports (SPIRs). us to run comprehensive testing programs. Velan also offers Maintenance Training courses on our Velan also has a long-standing entire product line to ensure history of partnering with major customers and service shops are architects/engineers and end aware of the latest and proper users to develop innovative solu- maintenance techniques on tions for their valving needs. Velan products. EnGinEErinG sErViCEs • Stress analysis and finite • Troubleshooting element analysis • Application engineering • System upgrades • Certified genuine spare parts • Flow analysis • Valve repair, refurbishment, • Weak link analysis and upgrading • Root cause failure analysis • Custom testing and test data analysis (NDT, X-Ray, UT, etc.) Velan supplies turn-key automated packages with integral control actuation • Commissioning for two wire and closed loop systems (Profibus, Modbus, Fieldbus, etc.). Velan reserves the right to change this information without notice. © 2009 Velan Inc. All rights reserved. 11

- 12. Velan’s extensive product range includes gate, globe, check, ball, triple-offset, and engineered severe service valves as well as steam traps — all of which are installed world-wide to handle diverse applications in the folowing industries: l Fossil, nuclear, and l Marine cogeneration power l Mining l Oil and gas l HVAC l Refining and petrochemicals l Water and wastewater l Chemicals and pharmaceutical l Pulp and paper l LNG and cryogenics Headquartered in Montreal, Canada, Velan has several international subsidiaries. For general inquiries: To find your local Velan representative: Velan head office 7007 Côte de Liesse, Montreal, QC H4T 1G2 Canada For more information about Velan, visit www.velan.com or call (514) 748-7743 Tel: (514) 748-7743 Fax: (514) 748-8635 Check our website for more specific contact information. www.velan.com © 2009 Velan Inc., Montreal, QC, Canada. All rights reserved. The contents hereof are confidential and proprietary to Velan. Any unauthorized reproduction or disclosure, in whole or in part, is strictly prohibited. Velan reserves the right to change this information without notice. Velan Valves, Velan Inc., Memoryseal, Securaseal, Torqseal, Proquip, Velflex, Adaxie, and RAMA are trademarks or registered trademarks of Velan Inc. and/or another Velan company. Stellite® is a registered trademark of Deloro Stellite Group. All other trademarks and registered trademarks are owned by their respective companies. BRO-FLB-12-09 Printed in Canada