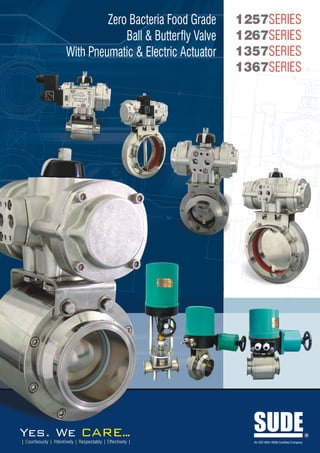

1257 1267 1357 1367 zero bacteria food grade valves

- 1. Zero Bacteria Food Grade 1257SERIES Ball & Butterfly Valve 1267SERIES With Pneumatic & Electric Actuator 1357SERIES 1367SERIES Yes. We ARE.. . | Courteously | Attentively | Respectably | Effectively | SUDE An ISO 9001:2008 Certified Company R

- 2. 2 Way / 3 Way Electric / Pneumatic Actuated Ball Valves Index Introduction - Zero Bacteria Introduction…………………………………. 01 Zero bacteria means a product which has to be free from impurities and their Key component areas along with important points which is to Materials & Material composition ....... 02 be covered in Ball valve and Butterfly valve are as follows: Applications…………………………….…… 02 1. Materials a) Body Materials Common terms and their definitions used for Zero Bacteria Valves…........... 05 b) Seat Materials c) Welded component Materials Comparison of Zero Bacteria and Diaphragm Valves …………………….….. 07 d) Stem seals e) End connections Ball Valves ………………………………….. 07 2. Surface Condition Technical Specifications of a) Mechanical polishing Ball Valves ……..................................... 08 b) Electro-polishing Exploded view of Ball Valve ……….…… 08 c) Surface finish Butterfly Valves …………………….……… 09 3. Drain ability a) Valve design for minimum hold-up volume Technical Specification of Butterfly Valves .....................................09 b) Installation Angles Exploded view of butterfly valve ……… 10 4. Material Composition a) 316L Electric Actuator ……………………….……10 b) Sulfur content Control Panel Specification ……….….… 11 c) Certification Pneumatic Actuator …………………….… 12 5. Inspection Exploded view of Pneumatic Actuator …13 6. Clean ability 7. Marking Information GA Drawings ……………………….……… 14 Seating material should meet the FDA guidelines 01 1257/1267/1357/1367SERIES SUDE

- 3. Materials & Material Composition The standard material used for zero bacteria valve The following are the list of tubing's and fittings to be is SS316L and its composition is as stated below used against each size valve (Refer table no.2) (Refer table no 1) Table 1 Table 2 CHEMICAL COMPOSITION % Nominal OD Tubing Sizes Carbon, MAX 0.035 Nominal Tube Tube Wall Hygienic Clamp Size In. OD (in) Thickness (in) Size. (in) Chromium 16.00-18.00 1” 1.000 0.065 1- ½ ” Manganese, Max 2.00 1- ½ ” 1.500 0.065 1- ½ ” Molybdenum 2.00-3.00 2” 2.000 0.065 2” Nickel 10.00-15.00 2- ½ “ 2.500 0.065 2-1/2” Phosphorus, MAX 0.04 3” 3.000 0.065 3” Silicon MAX 0.75 4” 4.000 0.0835 4” Sulfur 0.005-0.017 5” 5.000 0.109 5” Applications Bio-Pharm ? Pharmaceutical ? Food/Beverage ? Cosmetics ? Gas Delivery Systems ? Water Purification ? Brewing/Distilling ? Economical-compared to most other valve ? designs High flow rate through an unobstructed flow path ? ?quarter-turn operation Quick, ? automate pneumatically or electrically Easy to Inherently flexible to meet a wide range of ? ? – deliver alcohol to final product Alcohol pressures and temperatures (cosmetics) / cleaning ? maintainability Simple Clean Steam ? Self-flushing design ? WFI-Water for Injection ? ? – process temperature control/cleaning Steam Ultra filtration ? High purity Water – cleaning ? CDA-Clean Dry Air ? High purity gas – purging ? High Purity Water ? CDA (Clean Dry Air) – purging ? Alcohol ? SUDE 1257/1267/1357/1367SERIES 02

- 4. Surface Condition Under surface condition we should know what is polishing 4) Corrosion resistance is increased due to a and how they are important for zero bacteria valves. chromium enrichment of the surface and the removal of surface contaminants that may promote Mechanical polishing-Mill finishes welds and surfaces that corrosion have been in service have differing surface characteristics Stain less steel has a natural resistance to corrosion when viewed under magnification. Mechanical polishing due to its high chromium content (stainless steels are reduces all surface ridges, pits and discrepancies to typically 16% chromium or higher). Electro polishing uniform roughness. enhances this natural resistance because the process Mechanical polishing is accomplished utilizing aluminum dissolves more iron (Fe) than chromium (Cr). This oxide abrasives on rotary equipment. Mechanical leaves higher levels of chromium on the stainless steel polishing can be achieved by hand held tools for large surface. surface areas, such as reactors and vessels in place, or The result of any polishing procedure is to create a by automatic reciprocating machines for pipe or tubular “smooth” surface defined as the Roughness Average components. A series of grit polishes is applied in a (Ra) in micro inch (m-in) or micro-meter (mm). successively finer sequence until the desired finish or surface roughness is achieved. Surface smoothness is generally measured with a profilometer an automatic instrument with a stylus-type Electro polishing is the electrochemical removal of reciprocating arm. The stylus is traversed across a microscopic irregularities from metal surfaces. It results in metal surface, measuring peak height and valley depth. a general leveling or smoothing of the surface, that when The average peak height and valley depth is then viewed under magnification, appears virtually featureless. expressed as a roughness average in term of millionths As a result of electro polishing, a metal surface exhibits of an inch or micro inch, frequently referred to as Ra. the following properties : The relationship between polished and buffed mill 1) Surface roughness is significantly reduced, thus finishes, abrasive grit numbers and surface roughness- reducing adhesion properties before and after electro polishing is illustrated in the 2) Surface area is reduced as much as 7:1 following table (Refer table 3) 3) Surface friction and drag are reduced Table 3 Before Electro After Electro polishing Surface polishing Surface Roughness, Ra Roughness, Ra Girt Micro Micro Micro Micro No Meters Inches Meters Inches 120 1.14 max 45 max 0.88 -1.12 35 - 45 180 0.64 max 25 - 30 0.50 - 0.75 20 - 30 240 0.20 to 0.51 8 - 20 0.25 - 0.50 10 - 20 320 0.15 to 0.38 6 - 15 0.20 - 0.38 8 - 15 03 1257/1267/1357/1367SERIES SUDE

- 5. Drainability Drain ability is important for maintaining bioprocess where fluid accumulates also may become a systems in a clean and sterile condition. Fluid corrosion-initiation corner adding additional remaining after draining becomes a colonization site contaminants to the system and the design of the for bacterial or other microorganisms creating an valve it should be in such a way that this accumulation unacceptable bio burden to the system. A corner of product has to be minimized or to be removed. Clean Ability The following points are taken care while cleaning cold cleaning and de-greasing in a residue free the Zero bacteria valves: formulation. 1 Cleaning is performed in a room segregated from the 7 Each valve component is thoroughly washed in the normal valve production area to eliminate cleaning agent tank then rinsed in a de-ionized water contamination tank. The components are then dried in a hot air drying vessel. 2 The room is outfitted with one alkaline cleaning tank a DI rinse tank and a hot air drying tank 8 Valve assembly is performed on particle-free surface using latex gloves. Clean grease-free tools are used 3 Work areas are freshly covered with particles-free in the assembly of valves. plastic sheeting before each cleaning. 9 After assembly the valves are nitrogen purged with 4 Bubble-tight valve testing equipment utilizes clean, 99.999% pure N2 filters. dry, oil-free air. 10 The fully assembled valve is tested for leakage using 5 Capping and bagging is performed on the particle- clean, dry, oil-free air according to industry free surface. All bags are 4 mil and are heat – sealed standards. Double bag option is available 11 Each valve is capped, bagged and heat-sealed to 6 The basic cleaning is performed using an ultrasonic ensure product quality and purity until installed. cleaning system with an approved alkaline agent for Inspection & Marking All valves are inspected thoroughly to the required e) Color coded handles if applicable parameters particularly on the Body surface finish and All Zero bacteria valves when subjected to steam marking is done with the help of following information's: sterilization the valve should be designed to withstand a a) Heat number on each component part of the fitting if temperature of 150oC for duration of 100 hours under more than one heat is used continuous duty mode, of course elastomer has to be chosen properly otherwise the life of the same will be b) Material type reduced drastically. c) Specification number referencing the BPE standard d) Internal surface symbol for the appropriate BPE specification SUDE 1257/1267/1357/1367SERIES 04

- 6. Common Terms & Their Definitions Used For Zero Bacteria Valves Annealing : Clean steam: A treatment process for the purpose of reducing Steam free from boiler additives that may be purified, hardness, improving mach inability, facilitating cold filtered, or separated. Usually used for incidental working, or producing a desired mechanical physical, or heating in pharmaceutical applications. other property. Cloudiness: Aseptic : The appearance of a milky white hue across some Fee of pathogenic (causing or capable of causing portion of a surface resulting from the electro polish disease) microorganisms. process. Aseptic processing : Dead leg: Operating in a manner that prevents contamination of the process. An area of entrapment in a vessel or piping run that could lead to contamination of the product. Automatic welding : Demarcation: Welding with equipment that performs the welding operation without adjustment of the controls by a A localized area that is dissimilar to the surrounding welding operator. The equipment may or may not areas with a defined boundary after electro polishing. perform the loading and unloading of the work. Fermentation: Bio processing: The biochemical synthesis of organic compounds by The creation of a product utilizing living organisms. microorganisms or cultivated cells. Bio processing equipment : Ferment: Equipment, systems, or facilities used in the creation of A vessel for carrying out fermentation. products utilizing living organisms. Full penetration: Cavitations: A weld joint is said to be fully penetrated when the A condition of liquid flow where, after vaporization of the depth of the weld extends from its face into the weld liquid, the subsequent collapse or vapor bubbles can joint so that the joint is fully fused. For a tube-to-tube produce surface damage. weld, no unused portions of the weld joint shall be Certification: visible on the inside diameter of fully penetrated weld. Documented testimony by qualified authorities that a Heat number: system qualification, calibration, validation, or revalidation has been performed appropriately and that An alphanumeric identification of a stated tonnage of the results are acceptable. metal obtained from a continuous melting in a furnace. Clean: Hold-up-volume: Free of dirt, residues, detergents, or any contaminants The volume of liquid remaining in a vessel or piping that may affect or adulterate the product or process. system after it has been allowed to drain. Clean-in-place (CIP): Hydro test: Internally cleaning a piece of equipment without A pressure test of piping, pressure vessels, or relocation or disassembly. The equipment is cleaned pressure-containing parts, usually performed by but not necessarily sterilized. The cleaning is normally done by acid, caustic, or a combination of both, with pressurizing the internal volume with water at a Water-for-injection (WFI) rinse. pressure determined by the applicable code. 05 1257/1267/1357/1367SERIES SUDE

- 7. Hygienic : Pure steam: Of or pertaining to equipment and piping systems that Steam that is produced by a steam generator which, by design, materials of construction, and operation when condensed, meets requirements for Water-for- provided for the maintenance of cleanliness so that injection (WFI). products produced by these systems will not adversely affect human or animal health. Pyrogen: A fever-producing substance. Hygienic clamp joint: A tube outside diameter union consisting of two Ra: neutered ferrules having flat faces with a concentric Log of the arithmetic mean of the surface profile. groove and mating gasket that is secured with a Usually expressed in min as related to roughness. clamp, providing a non protruding, recess less product contact surface. Self-draining: Machine welding: The elimination of all fluid from the system due to the force of gravity alone. Welding with equipment that performs the welding operation under the constant observation and control Square cut: of a welding operator. The equipment may or may not perform the loading and unloading of the works. A tube end cut perpendicular to the tangent plane. Micron or micrometer (mm): Steam in place (SIP): One-millionth of a meter. The use of steam to sanitize or sterilize a piece of equipment without the use an autoclave. Orange peel: Sterile: An appearance of a pebbly surface. Free living organisms. Passivation: Surface Inclusion: A final treatment/cleaning process used to remove free iron or other anodic contaminants from the surface of Particles of foreign material in a metallic matrix. The corrosion-resistant steel parts such that uniform particles are usually compounds such as oxides, formation of a passive layer is obtained. sulfides, or silicates, but may be a substance foreign to and essentially insoluble in the matrix. Passive layer: Surface residual: A passive oxidized film that forms naturally on the A foreign substance that adheres to a surface by stainless steel surface when exposed to air or similar chemical reaction, adhesion, adsorption, or ionic oxidizing environment protecting the underlying base bonding (for example, corrosion, rouging, and metal from corrosion. staining). Pipe: Tube: Pipe size is determined by diameter and schedule. Tube is sized by its nominal outside diameter. For bio- For bioprocess equipment, pipe does not include tube processing equipment, tube does not include pipe. Porosity: Cavity-type discontinuities formed by gas entrapment during solidification. SUDE 1257/1267/1357/1367SERIES 06

- 8. Comparision Of Zero Bacteria And Diaphragm Valves Zero Bacteria valves are widely used in process applications because of their inherent versatility. Diaphragm valves offer a limited service range for temperature and pressure and do not meet all of the standards for industrial valves. Zero Bacteria valves are available for: Cryogenic service High temperature / Low temperature High velocity / Low velocity High pressure / Low pressure Wider range of seat materials wider range of body materials Wider range of end connections Fire-safe designs In addition, zero bacteria valve center sections are removable to allow access to the inner weld bead where cleaning and/or polishing may then be performed. Ball Valve A Precision ball with a full port is positioned inside the Available Sizes: valve body between two flanges and two PTFE valve seats. The 90° rotation of the valve stem, through the 1”, 1 ½”, 2”, 2 ½”, 3”, 4” handle or a pneumatic / Electrical actuator, is transferred, to the ball thereby opening or closing the Available Types: valve. Butt weld Standard Design: Sanitary Clamp The valve consists of a valve body, two flanges, PTFE I-Line valve seats, EPDM O-ring, ball, stem and a handle or actuator. All Seats and seals are made from FDA approved material. End connections: The Valve body, flanges and ball are made of forged Sanitary Clamp, Butt-Weld, Extended Butt Weld (for 316L stainless steel which ensures non porous, high purity applications), I-Line or others on request. smooth and dimensionally stable construction. Materials: The valve is designed to maintain a full rate, with a minimum pressure drop and it is fully drainable. AISI 316L or AISI 304L A Bottom entry, precision machined stem with a live loaded PTFE thrust washer ensures a Smooth rotation Actuator option: at various temperatures and pressure Conditions. Electrical/Pneumatic 900 Open/ Close Purge ports are provided on the valve body for SIP / CIP applications 07 1257/1267/1357/1367SERIES SUDE

- 9. Technical Specifications of Ball Valve Material : Product wetted steel parts …… AISI 316L/AISI 304L Other steel parts …… AISI 304 FDA Seals : Valve Seat …… TFM / PTFE O-ring …… EPDM Cavity filler (optional) …… TFM /PTFE Nominal Pressure : Maximum product pressure …… 200 PSI maximum (14 Bars) Test pressure 235 PSI (16 Bars) Temperature Range : …… 60' Degrees Fahrenheit to +300' Degrees Fahrenheit *Other seal material available for higher temperatures Surface Finish: Contact with product …… Ra</=25µ in (Girt 220g) Optional …… Ra</=15µ in (Girt 320g) Connections : …… Sanitary Clamp (ISO 2852/BS 4825-3) Optional : …… Butt Weld (ISO 2037/BS 4825-01) I-Line, Other connections on request Purge Port Connections : …… 1/4” Males BSP (Refer figure no.1) Exploded View of Standard Ball Valve 13 12 11 10 9 5 8 4 3 15 1 6 14 2 7 Fig. 1 Sl. No. Description Material Sl. No. Description Material 1 BODY AISI 316L/AISI 304L 9 STEM AISI 316L/AISI 304L 2 O-RING EPDM 10 THRUST RING PTFE 3 O-RING EPDM 11 O-RING EPDM 4 FLANGE AISI 316L/AISI 304L 12 INDEX BASE AISI 304 5 CAP SCREW AISI 304 13 THRUST WASHER PTFE 6 BALL AISI 316L/AISI 304L 14 DRAIN CAP AISI 316L/AISI 304L 7 SEAT TFM PTFE 15 WASHER PTFE 8 BUSHING PTFE SUDE 1257/1267/1357/1367SERIES 08

- 10. Butterfly Valve Working Principle: Available Types: Quarter turn (90º rotation) operation closes or opens ? Butt-Weld the valve. A wide variety of actuators allow the valve ? Sanitary Clamp disc to be set at various positions so that the flow rate ? I-Line can be regulated. Options: Standard Design: ? Variety of multiple position handles for manual The valve consists of two valve bodies and a disc made operation. from forged stainless steel which ensures a non porous, smooth surface and dimensionally stable construction. ? Automatic operation by vertical pneumatic / electrical The valve disc has a dense and polished surface which actuators combined with a slim design allows for a high Cv. The PTFE stem bushing ensures an extra smooth disc End Connections : rotation. All seats and seals are made from FDA Sanitary Clamp, Butt-Weld, I-Line, or others on approved materials. The valves are assembled by request. means of Allen head cap screws. Material: Available Sizes: AISI 316L or AISI 304L 1”, 1 ½”, 2”, 2 ½”, 3”, 4”, 5”, 6”, 8” Technical Specification of Ball Valve Material : Product wetted steel parts …… AISI 316L or AISI 304L Other steel parts …… AISI 304 FDA Seals : Standard …… SILICONE Optional …… VITON, EPDM, BUNA, PTFE Nominal Pressure: Maximum Product Pressure …… 147 PSI maximum (10 Bars) Test pressure 176 PSI (12 Bars) Surface Finish: Surface in contact with product …… Ra </= 25 µ in (Grit 220g) Optional …… Ra </= 25 µ in (Grit 320g) Connections …… Sanitary Clamp (ISO 2852 / BS 4825) Optional …… Butt Weld (ISO 2037 / BS 4825), I-Line (Refer figure No. 2) 09 1257/1267/1357/1367SERIES SUDE

- 11. Exploded View of Standard Butterfly Valve 2 Sl. No. Description Material 1 DISC AISI 316L/AISI 304L 2 BUSHING PTFE 3 FLANGE AISI 316L/AISI 304L 1 4 SEAT SILICONE 5 SCREW AISI 304 5 Fig. 2 4 2 3 Electrical Actuator Easier interface with digital control devices. Electrical actuators must have a voltage selection, typical actuators voltages are 24V AC, 110V AC, 240 V AC and 415 Volts. Fail safe electric actuators are also called spring return and the fail positioning (open or closed) should be noted. For detail on the Electric actuator refer Sdtork pune and asked for detailed literature. The spring return Electrical actuators are available for low torque, for higher values we suggest you to use reversible stay put type actuator Actuator Construction Single Phase Single phase SDTORK Actuator is provided with Stall duty motor used for quarter turn application. Actuator is suitable for inching operation too and they can be supplied with extra limit switches for remote position indication. The Actuator are available in general purpose, Dust proof & Flame proof & Explosion proof housing approved by CMRS Dhanbad. Three phases SDTORK Actuator is basically a worm gear type reduction gear box. A single stage grease bath worm gear gives quietness and reliability in operation. The valve can be fully opened, fully closed or adjusted to any intermediate position. The rectory force on the worm shaft which is a 'Floating one' is directly proportional to the out put torque and is absorbed by a set of disc springs. The lateral movement of the worm shaft under load, trips closes the Torque switch. SUDE 1257/1267/1357/1367SERIES 10

- 12. Three Phase Three phase Actuator are fitted with torque limit switches & travel limit switches & also they are in built with manual hand wheel used for operating the actuator manually in case of power failure. Actuator is also supplied with various shaft designs to suit rising & non rising stem valve. Three phases are also provided with space heater. This actuator is also available in slow mode operation which is used for multi turn application. The driving motor is a TEFC squirrel cage class F IP 65 enclosure motor combining low inertia with a high starting and stalling torque. Accessories For Actuator a) Travel Limit Switches - 2 nos Actuator can also be supplied with : Single Phase OR Three phase Panel for switching the valve On / Off through Push b) Auxiliary Limit Switches - 2 nos Buttons for local operation under manual mode OR through PLC under Auto mode c) Hand wheel for Manual operation through 4-20 mA, 0 to 10 V DC. d) Local position indicator Common Accessory for Single Phase / Three Phase Actuator : a) Honeywell / any other make PID Controller along with PT 100 sensor with e) Potentiometer for feed back built in panel as an option. f) Torque limit switches b) Honeywell / any other make pressure Transmitter where based on setting pressure valve will open & close through PID with built in panel as a option. g) Position Transmitter c) Sequential timer 0 to 30 channel for sequence operation. d) Cyclic timer having On time - 1 to 60 seconds & Off time - 1 to 60 min for sequencing operation. The Actuators can be supplied with e) Stimulator –panel mounting type having two knobs used for generating a panel having Auto Calibration facility. 4 to 20mA with the help of 230 Volt A.C. Supply. Control Panel Specification a) Input : Single Phase 230 V AC OR 3 Phase 415 V AC, 4 wire supply. Fig. 3 b) Output supply: Single Phase 230 V AC OR 3 phase 415 V AC Reversible supply. c) Auto / Manual selection : Selector switch provided. In Auto mode open & close operation is controlled by 4-20mA Input & under Manual mode Wall Mounted Construction operation is through Push buttons. in sheet metal d) Indications : Zero to a100% valve position display, R, Y, B Phase Indication [applicable only for 3 phase] Open & Close, Fully open & Fully close indication. e) Main switch - Single Phase OR 3 Phase MCB for mains On / Off. f) Phase fail / error protection provided. g) Fuse protection provided for each phase. h) Protection from over torque - If Actuator gets over torque the torque switch trips & the system protects the motor. Also provided with 10 meters cable for Motor & Feed back with connectors. (Fig. 3) Integral Construction 11 1257/1267/1357/1367SERIES SUDE

- 13. Pneumatic Actuator Pneumatic actuators are available in rotary construction in Double and spring return in on/off and modulating duty format. Actuators will be inherently fail safe but fail position (open or closed) should be noted. Pneumatic actuators are supplied with Electro pneumatic petitioners which work on continuous pressurized air of 60psi and input signal of 4 to 20mA with feed back 4to20ma For details refer Actuator catalogue. Actuator Construction The piston incorporates racks and end covers are die Air Pressure Requirement : casted in aluminum alloy. Barrel is extruded. a) For Double Acting Actuator - 3.5 kg / cm2 aluminium alloy hardened and treated, further finished (Minimum) & 8.5kg / cm2 (Maximum) with deep anodized process to form a protective layer b) For Spring Return Actuator - 4.0 kg / cm2 to resist atmospheric corrosion. The actuators are also (Minimum) & 8.5 kg / cm2 (Maximum) available in stainless steel 316 & Nylon plastic However Air Pressure Requirement is much construction for food grade and chemical industries dependent on size of the valve, working pressure, application. The internal materials of the actuator are quality of Butterfly valve and many other factors. having pinion which is made up of steel, precision cut, For Double Acting Actuator: heat treated and ground & also has a high trade of 4 way 5 port single Coil / Double Coil solenoid valve in synthetic seals. The actuators before assembly is general purpose or Flame proof and explosion coils lubricated with high temperature resistant smooth construction. grease. The actuators are with compact design For Spring Return Actuator: operates through 90 degree angle of actuation. The 3 way Single Coil / Double Coil solenoid valve in Actuator is also available in 180 degree rotation. Refer General purpose or Flame proof and explosion Coils Fig. 4 construction. Accessories Accessory Common for Double Acting / i) Position Transmitter Spring Return Actuator : j) Cyclic Timer OR Sequential Timer a) Pressure Regulator k) 3 Way / 4 Way Key operated valves b) Limit Switches l) Stimulator c) Filter Regulator with Lubricator m) Travel Stops d) Gear Box with hand wheel for manual operation n) Flow Restricter e) Valve Positioner for characteristic controlled o) Silencers with Flow Control Valve application. Optional : f) I to P Converter. a) PID Controller along with PT - 100 Senso g) Electro pneumatic positioners supplied with panel. h) Position Indicator b) Pressure Transmitter supplied with panel. SUDE 1257/1267/1357/1367SERIES 12

- 14. Tests The valves are tested according to their respective standards for hydrostatic, seat leakage and working pressure tests. Unless and otherwise specified Ball valves are Constructed and tested for10 kg/cm2 working pressure. Notes : a) Actuator rating is for valve working pressure 10 kg / cm2 b) Timing given is approximate and is useful as an indicating figure only when solenoid valve is directly coupled with the Actuator. Average time under 50% load condition is 80 PSI working pressure. c) All data is complied in laboratory test, in actual field, working may differ. d) Width and weight will change with rating of flanges and accessories. Exploded View of Pneumatic Actuator 9 7 8 6 5 4 13 3 2 1 12 10 15 14 11 14 Fig. 4 No. Description Quantity Material 1 Allen Screw 12 AISI -304 Stainless Steel 2 Double Acting Cap 2 Aluminium Alloy (2) + (1) 3 Cap O-ring 2 N.B.R. 4 Piston 2 Aluminium Alloy 5 Cylinder 1 Aluminium Alloy (2) + (1) 6 Washer 1 Polyamide 6 7 Spring Clip 1 Steel (3) 8 Position Indicator 1 Polymide 9 Piston Guide 4 P.T.F.E. + Bronze 10 Guide Ring 2 P.T.F.E. + Bronze 11 Piston O-Ring 4 N.B.R. 12 O-Ring 2 N.B.R. 13 O-Ring 2 N.B.R. 14 Springs Set 1 DIN - 17223-C (2) (4) 15 Spring Return Cap 2 Aluminium Alloy (2) + (1) 16 Shaft 1 Steel (2) 17 Gear 1 Aluminium Alloy (5) 18 Watertightness Plane Gasket 2 N.B.R. 13 1257/1267/1357/1367SERIES SUDE

- 15. Butt-Weld Metalic Ball Valve with Pneumatic Rotary Single/Double Acting Actuator 1367 H G D E F 1 I 7 5 6 2 3 4 K L 9 12 J 10 C B 11 A 8 BILL OF MATERIAL OF VALVE WITH ACTUATOR S.No. PART MATERIALS 1 INDICADOR VISUAL POSITION INDICATOR -- 2 PISTON GUIDE POLYACETAL 3 GUIDE RING POLYACETAL 4 PISTON O-RING NITRILE 5 TAPA DOBLEEFECTO DOUBLE ACTING CAP -- 6 SPRING SET DIN-17223-C 7 SPRING RETURN CAP ALLUMININUM ALLOY 8 BODY AISI316L 9 FLANGE AISI316L 10 CAP SCREW AISI 304 11 O-RING EPDM 12 SEAT TFM PTFE DIMENSIONS (MM) APPROX. AIR CONSUMP- VALVE MODEL NUMBER TIME TION IN LTR WT. OF SIZE Cv ASSY A B C D E F G H I J K L FOR FOR FOR FOR Value IN KGS. OPEN CLOSE OPEN CLOSE 1367/25/BW/AISI316L/AISI316L/DAW 94.05 34.13 22.22 8 7.5 20 109 85 72.23 157.23 191.36 0.2 0.2 0.075 0.05 66 2.15 25 1367/25/BW/AISI316L/AISI316L/SAW 94.05 34.13 22.22 8 7.5 20 143.5 85 72.23 157.23 191.36 0.3 0.3 0.075 66 2.3 1367/40/BW/AISI316L/AISI316L/DA00 107.15 41.27 34.92 10 11 30 125 110 81.35 191.35 232.62 0.3 0.3 0.15 0.1 192 2.9 40 1367/40/BW/AISI316L/AISI316L/SA00 107.15 41.27 34.92 10 11 30 160.00 110 81.35 191.35 232.62 0.3 0.3 0.15 192 3.15 1367/50/BW/AISI316L/AISI316L/DA05 117.07 49.21 47.62 10 11 30 146 122 98.42 220.42 269.63 0.4 0.4 0.28 0.25 434 4.1 50 1367/50/BW/AISI316L/AISI316L/SA05 117.07 49.21 47.62 10 11 30 194.00 122 98.42 220.42 269.63 0.4 0.4 0.28 434 4.9 1367/65/BW/AISI316L/AISI316L/DA10 135.73 59.53 60.32 10 11 30 182 127 107.15 234.15 293.68 0.5 0.5 0.33 0.32 723 6.47 65 1367/65/BW/AISI316L/AISI316L/SA10 135.73 59.53 60.32 10 11 30 236.00 127 107.15 234.15 293.68 0.5 0.5 0.33 723 7.18 1367/80/BW/AISI316L/AISI316L/DA10 157.95 65.88 72.62 10 11 30 182 127 114.3 241.3 307.18 0.5 0.5 0.33 0.32 1124 10.37 80 1367/80/BW/AISI316L/AISI316L/SA15 157.95 65.88 72.62 10 11 30 236.00 127 114.3 241.3 307.18 0.6 0.6 0.33 1124 12.45 1367/100/BW/AISI316L/AISI316L/DA15 170.25 86.91 97.63 10 11 30 203 148 127.00 275.00 361.91 0.8 0.8 0.8 0.7 2100 17.1 100 1367/100/BW/AISI316L/AISI316L/SA20 170.25 86.91 97.63 10 11 30 266.00 148 127.00 275.00 361.91 1.0 1.0 0.8 2100 20.26 SUDE 1257/1267/1357/1367SERIES 14

- 16. Sanitary Clamp Metalic Ball Valve with Pneumatic Rotary Single/Double Acting Actuator 1367 H G D E F 1 I 7 5 6 2 3 4 K L 9 12 J 10 C B 11 A 8 BILL OF MATERIAL OF VALVE WITH ACTUATOR S.No. PART MATERIALS 1 INDICADOR VISUAL POSITION INDICATOR -- 2 PISTON GUIDE POLYACETAL 3 GUIDE RING POLYACETAL 4 PISTON O-RING NITRILE 5 TAPA DOBLEEFECTO DOUBLE ACTING CAP -- 6 SPRING SET DIN-17223-C 7 SPRING RETURN CAP ALLUMININUM ALLOY 8 BODY AISI316L 9 FLANGE AISI316L 10 CAP SCREW AISI 304 11 O-RING EPDM 12 SEAT TFM PTFE DIMENSIONS (MM) APPROX. AIR CONSUMP- VALVE MODEL NUMBER TIME TION IN LTR WT. OF SIZE Cv ASSY A B C D E F G H I J K L FOR FOR FOR FOR IN KGS. OPEN CLOSE OPEN CLOSE 1367/25/SC/AISI316L/AISI316L/DAW 94.05 34.13 22.22 8 7.5 20 109 85 72.23 157.23 191.36 0.2 0.2 0.075 0.05 66 2.65 25 1367/25/SC/AISI316L/AISI316L/SAW 94.05 34.13 22.22 8 7.5 20 143.5 85 72.23 157.23 191.36 0.3 0.3 0.075 66 2.8 1367/40/SC/AISI316L/AISI316L/DAOO 107.15 41.27 34.92 10 11 30 125 110 81.35 191.35 232.62 0.3 0.3 0.15 0.1 192 3.4 40 1367/40/SC/AISI316L/AISI316L/SA00 107.15 41.27 34.92 10 11 30 160.00 110 81.35 191.35 232.62 0.3 0.3 0.15 192 3.65 1367/50/SC/AISI316L/AISI316L/DA05 117.07 49.21 47.62 10 11 30 146 122 98.42 220.42 269.63 0.4 0.4 0.28 0.25 434 4.6 50 1367/50/SC/AISI316L/AISI316L/SA05 117.07 49.21 47.62 10 11 30 194.00 122 98.42 220.42 269.63 0.4 0.4 0.28 434 5.4 1367/65/SC/AISI316L/AISI316L/DA10 135.73 59.53 60.32 10 11 30 182 127 107.15 234.15 293.68 0.5 0.5 0.33 0.32 723 6.97 65 1367/65/SC/AISI316L/AISI316L/SA10 135.73 59.53 60.32 10 11 30 236.00 127 107.15 234.15 293.68 0.5 0.5 0.33 723 7.68 1367/80/SC/AISI316L/AISI316L/DA10 157.95 65.88 72.62 10 11 30 182 127 114.3 241.3 307.18 0.5 0.5 0.33 0.32 1124 10.87 80 1367/80/SC/AISI316L/AISI316L/SA15 157.95 65.88 72.62 10 11 30 236.00 127 114.3 241.3 307.18 0.6 0.6 0.33 1124 12.95 1367/100/SC/AISI316L/AISI316L/DA15 170.25 86.91 97.63 10 11 30 203 148 127.00 275.00 361.91 0.8 0.8 0.8 0.7 2100 17.6 100 1367/100/SC/AISI316L/AISI316L/SA20 170.25 86.91 97.63 10 11 30 266.00 148 127.00 275.00 361.91 1.0 1.0 0.8 2100 20.76 15 1257/1267/1357/1367SERIES SUDE

- 17. I-Line Metalic Ball Valve with Pneumatic Rotary Single/Double Acting Actuator 1367 H G D E F 1 I 7 5 6 2 3 4 K L 9 12 J 10 C B 11 A 8 BILL OF MATERIAL OF VALVE WITH ACTUATOR S.No. PART MATERIALS 1 INDICADOR VISUAL POSITION INDICATOR -- 2 PISTON GUIDE POLYACETAL 3 GUIDE RING POLYACETAL 4 PISTON O-RING NITRILE 5 TAPA DOBLEEFECTO DOUBLE ACTING CAP -- 6 SPRING SET DIN-17223-C 7 SPRING RETURN CAP ALLUMININUM ALLOY 8 BODY AISI316L 9 FLANGE AISI316L 10 CAP SCREW AISI 304 11 O-RING EPDM 12 SEAT TFM PTFE DIMENSIONS (MM) APPROX. AIR CONSUMP- VALVE MODEL NUMBER TIME TION IN LTR WT. OF SIZE Cv ASSY A B C D E F G H I J K L FOR FOR FOR FOR IN KGS. OPEN CLOSE OPEN CLOSE 1367/25/IL/AISI316L/AISI316L/DAW 101.99 34.13 22.22 8 7.5 20 109 85 72.23 157.23 191.36 0.2 0.2 0.075 0.05 66 3.09 25 1367/25/IL/AISI316L/AISI316L/SAW 101.99 34.13 22.22 8 7.5 20 143.5 85 72.23 157.23 191.36 0.3 0.3 0.075 66 3.24 1367/40/IL/AISI316L/AISI316L/DAOO 109.93 41.27 34.92 10 11 30 125 110 81.35 191.35 232.62 0.3 0.3 0.15 0.1 192 3.88 40 1367/40/IL/AISI316L/AISI316L/SA00 109.93 41.27 34.92 10 11 30 160.00 110 81.35 191.35 232.62 0.3 0.3 0.15 192 4.13 1367/50/IL/AISI316L/AISI316L/DA05 140.49 49.21 47.62 10 11 30 146 122 98.42 220.42 269.63 0.4 0.4 0.28 0.25 434 5.22 50 1367/50/IL/AISI316L/AISI316L/SA05 140.49 49.21 47.62 10 11 30 194.00 122 98.42 220.42 269.63 0.4 0.4 0.28 434 6.02 1367/65/IL/AISI316L/AISI316L/DA10 142.08 59.53 60.32 10 11 30 182 127 107.15 234.15 293.68 0.5 0.5 0.33 0.32 723 8.02 65 1367/65/IL/AISI316L/AISI316L/SA10 142.08 59.53 60.32 10 11 30 236.00 127 107.15 234.15 293.68 0.5 0.5 0.33 723 8.73 1367/80/IL/AISI316L/AISI316L/DA10 170.65 65.88 72.62 10 11 30 182 127 114.3 241.3 307.18 0.5 0.5 0.33 0.32 1124 12.67 80 1367/80/IL/AISI316L/AISI316L/SA15 170.65 65.88 72.62 10 11 30 236.00 127 114.3 241.3 307.18 0.6 0.6 0.33 1124 14.75 1367/100/IL/AISI316L/AISI316L/DA15 202.00 86.91 97.63 10 11 30 203 148 127.00 275.00 361.91 0.8 0.8 0.8 0.7 2100 20.6 100 1367/100/IL/AISI316L/AISI316L/SA20 202.00 86.91 97.63 10 11 30 266.00 148 127.00 275.00 361.91 1.0 1.0 0.8 2100 23.76 SUDE 1257/1267/1357/1367SERIES 16

- 18. Butt-Weld Metalic Butterfly Valve with Pneumatic Rotary Single/Double Acting Actuator 1267 H G D E F 4 1 J 2 3 5 6 7 K M 8 9 D 8 B A L 10 C BILL OF MATERIAL OF VALVE WITH ACTUATOR S.No. PART MATERIALS 1 TAPA DOUBLE EFECTO DOUBLE ACTING CAP -- 2 SPRING SET DIN-17223-C 3 SPRING RETURN CAP ALLUMINIUM ALLOY 4 VISUAL POSITION INDICATOR -- 5 PISTON GUIDE POLYACETAL 6 GUIDE RING POLYACETAL 7 PISTON O-RING NITRILE 8 FLANGE AISI 316L 9 SCREW AISI 304 10 SEAT SILICON DIMENSIONS (MM) OPPROX. AIR CONSUMP- VALVE MODEL NUMBER TIME TION IN LTR WT. OF SIZE Cv ASSY A B C D E F G H I J K L M FOR FOR FOR FOR IN KGS. OPEN CLOSE OPEN CLOSE 1267/25/BW/AISI316L/AISI316L/DAW 22.22 25.4 68.07 84.82 143.5 109.00 8.00 7.5 20.00 85.00 169.82 79.24 209.44 22 0.2 0.2 0.075 0.05 1.05 25 1267/25/BW/AISI316L/AISI316L/SAW 22.22 25.4 68.07 84.82 143.5 109.00 8.00 7.5 20.00 85.00 169.82 79.24 209.44 22 0.3 0.3 0.075 1.2 1267/25/BW/AISI31 6L/AISI31 6L/DAW 34.92 38.1 76.2 87.36 143.5 109.00 8.00 7.5 20.00 85.00 172.36 84.83 214.77 80 0.2 0.2 0.075 0.05 1.15 40 1267/25/BW/AISI31 6L/AISI31 6L/SAW 34.92 38.1 76.2 87.36 143.5 109.00 8.00 7.5 20.00 85.00 172.36 84.83 214.77 80 0.3 0.3 0.075 1.15 1267/25/BW/AISI31 6L/AISI31 6L/DA00 47.62 50.8 80.01 97.52 160.00 125.00 10.00 11.00 30.00 110.00 207.52 104.64 259.84 195 0.3 0.3 0.15 0.1 3.1 50 1267/25/BW/AISI31 6L/AISI31 6L/SA00 47.62 50.8 80.01 97.52 160.00 125.00 10.0 11.00 30.00 110.00 207.52 104.64 259.84 195 0.4 0.4 0.15 2.25 1267/25/BW/AISI31 6L/AISI31 6L/DA00 60.32 63.5 80.01 101.85 160.00 125.00 10.00 11.00 30.00 110.00 211.85 111.76 268.73 250 0.3 0.3 0.15 0.1 3.5 65 1267/25/BW/AISI31 6L/AISI31 6L/SA05 60.32 63.5 80.01 101.85 160.00 125.00 10.00 11.00 30.00 110.00 211.85 111.76 268.73 250 0.4 0.4 0.15 3.7 1267/25/BW/AISI31 6L/AISI31 6L/DA05 72.61 76.2 80.01 107.95 194.00 146.00 10.00 11.00 30.00 122.00 229.95 124.46 292.18 400 0.4 0.4 0.28 0.25 3 80 1267/25/BW/AISI31 6L/AISI31 6L/SA05 72.61 76.2 80.01 107.95 194.00 146.00 10.00 11.00 30.00 122.00 229.95 124.46 292.18 400 0.4 0.4 0.15 3.8 1267/25/BW/AISI31 6L/AISI31 6L/DA05 97.61 101.6 88.9 124.61 194.00 146.00 10.00 11.00 30.00 122.00 246.61 156.97 325.09 840 0.4 0.4 0.28 0.25 4.5 100 1267/25/BW/AISI31 6L/AISI31 6L/SA10 97.61 101.6 88.9 124.61 194.00 146.00 10.00 11.00 30.00 122.00 246.61 156.97 325.09 840 0.5 0.5 0.28 5.58 1267/25/BW/AISI316L/AISI316L/DA10 121.43 127 88.9 149.86 236.00 182.00 10.00 11.00 30.00 127.00 276.86 180.08 366.9 1200 0.5 0.5 0.33 0.32 6.57 125 1267/25/BW/AISI31 6L/AISI31 6L/SA15 121.43 127 88.9 149.86 236.00 182.00 10.00 11.00 30.00 127.00 276.86 180.08 366.9 1200 0.6 0.6 0.33 8.65 1267/25/BW/AISI316L/AISI316L/DA15 146.83 152.4 89.07 165.86 266.00 203.00 10.00 11.00 30.00 148.00 313.86 211.83 419.77 1900 0.8 0.8 0.8 0.7 7.8 150 1267/25/BW/AISI31 6L/AISI31 6L/SA20 146.83 152.4 89.07 165.86 266.00 203.00 10.00 11.00 30.00 148.00 313.86 211.83 419.77 1900 1 1 0.8 10.96 1267/25/BW/AISI31 6L/AISI31 6L/DA20 200.02 203.2 89.66 187.96 312.00 234.00 16.00 11.00 30.00 161.00 348.96 256.28 477.1 3200 1 1 1.5 1.2 11.07 200 1267/25/BW/AISI31 6L/AISI31 6L/SA25 200.02 203.2 89.66 187.96 312.00 234.00 16.00 11.00 30.00 161.00 348.96 256.28 477.1 3200 1.6 1.6 1.5 0.7 16.7 17 1257/1267/1357/1367SERIES SUDE

- 19. Sanitary Clamp Metalic Butterfly Valve with Pneumatic Rotary Single/Double Acting Actuator 1267 D E F G H 4 1 I 2 3 5 6 7 J L 8 9 C 8 A K 10 B BILL OF MATERIAL OF VALVE WITH ACTUATOR S.No. PART MATERIALS 1 TAPA DOUBLE EFECTO DOUBLE ACTING CAP -- 2 SPRING SET DIN-17223-C 3 SPRING RETURN CAP ALLUMINIUM ALLOY 4 VISUAL POSITION INDICATOR -- 5 PISTON GUIDE POLYACETAL 6 GUIDE RING POLYACETAL 7 PISTON O-RING NITRILE 8 FLANGE AISI 316L 9 SCREW AISI 304 10 SEAT SILICON DIMENSIONS (MM) OPPROX. AIR CONSUMP- VALVE MODEL NUMBER TIME TION IN LTR WT. OF SIZE Cv ASSY A B C D E F G H I J K L OPEN CLOSE TO TO IN KGS. (SEC.) (SEC.) OPEN CLOSE 1267/25/SC/AISI316L/AISI316L/DAW 22.22 68.07 84.82 143.5 109.00 8.00 7.5 20.00 85.00 169.82 79.24 209.44 22 0.2 0.2 0.075 0.05 1.25 25 1267/25/SC/AISI316L/AISI316L/SAW 22.22 68.07 84.82 143.5 109.00 8.00 7.5 20.00 85.00 169.82 79.24 209.44 22 0.3 0.3 0.075 1.4 1267/25/SC/AISI316L/AISI316L/DAW 34.92 76.2 87.36 143.5 109.00 8.00 7.5 20.00 85.00 172.36 84.83 214.77 80 0.2 0.2 0.075 0.05 1.3 40 1267/25/SC/AISI316L/AISI316L/SAW 34.92 76.2 87.36 143.5 109.00 8.00 7.5 20.00 85.00 172.36 84.83 214.77 80 0.3 0.3 0.075 1.45 1267/25/SC/AISI316L/AISI316L/DA00 47.62 80.01 97.52 160.00 125.00 10.00 11.00 30.00 110.00 207.52 104.64 259.84 195 0.3 0.3 0.15 0.1 3.5 50 1267/25/SC/AISI316L/AISI316L/SA00 47.62 80.01 97.52 160.00 125.00 10.00 11.00 30.00 110.00 207.52 104.64 259.84 195 0.4 0.4 0.15 2.65 1267/25/SC/AISI316L/AISI316L/DA00 60.32 80.01 101.85 160.00 125.00 10.00 11.00 30.00 110.00 211.85 111.76 268.73 250 0.3 0.3 0.15 0.1 3.9 65 1267/25/SC/AISI316L/AISI316L/SA05 60.32 80.01 101.85 160.00 125.00 10.00 11.00 30.00 110.00 211.85 111.76 268.73 250 0.4 0.4 0.15 4.1 1267/25/SC/AISI316L/AISI316L/DA05 72.61 80.01 107.95 194.00 146.00 10.00 11.00 30.00 122.00 229.95 124.46 292.18 400 0.4 0.4 0.28 0.25 3.5 80 1267/25/SC/AISI316L/AISI316L/SA05 72.61 80.01 107.95 194.00 146.00 10.00 11.00 30.00 122.00 229.95 124.46 292.18 400 0.4 0.4 0.15 4.3 1267/25/SC/AISI316L/AISI316L/DA05 97.61 88.9 124.61 194.00 146.00 10.00 11.00 30.00 122.00 246.91 156.97 325.09 840 0.4 0.4 0.28 0.25 5 100 1267/25/SC/AISI316L/AISI316L/SA10 97.61 88.9 124.61 194.00 146.00 10.00 11.00 30.00 122.00 246.91 156.97 325.09 840 0.5 0.5 0.28 6.08 1267/25/SC/AISI316L/AISI316L/DA10 121.43 88.9 149.86 236.00 182.00 10.00 11.00 30.00 127.00 276.86 180.08 366.9 1200 0.5 0.5 0.33 0.32 7.07 125 1267/25/SC/AISI316L/AISI316L/SA15 121.43 88.9 149.86 236.00 182.00 10.00 11.00 30.00 127.00 276.86 180.08 366.9 1200 0.6 0.6 0.33 9.15 1267/25/SC/AISI316L/AISI316L/DA15 146.83 89.07 165.86 266.00 203.00 10.00 11.00 30.00 148.00 313.86 211.83 419.77 1900 0.8 0.8 0.8 0.7 8.6 150 1267/25/SC/AISI316L/AISI316L/SA20 146.83 89.07 165.86 266.00 203.00 10.00 11.00 30.00 148.00 313.86 211.83 419.77 1900 1 1 0.8 11.76 1267/25/SC/AISI316L/AISI316L/DA20 200.02 89.66 187.96 312.00 234.00 16.00 11.00 30.00 161.00 348.96 256.28 477.1 3200 1 1 1.5 1.2 11.77 200 1267/25/SC/AISI316L/AISI316L/SA25 200.02 89.66 187.96 312.00 234.00 16.00 11.00 30.00 161.00 348.96 256.28 477.1 3200 1.6 1.6 1.5 0.7 17.4 SUDE 1257/1267/1357/1367SERIES 18

- 20. I-Line Metalic Butterfly Valve with Pneumatic Rotary Single/Double Acting Actuator 1267 D E F G H 4 1 I 2 3 5 6 7 J L 8 9 C 8 A K 10 B BILL OF MATERIAL OF VALVE WITH ACTUATOR S.No. PART MATERIALS 1 TAPA DOUBLE EFECTO DOUBLE ACTING CAP -- 2 SPRING SET DIN-17223-C 3 SPRING RETURN CAP ALLUMINIUM ALLOY 4 VISUAL POSITION INDICATOR -- 5 PISTON GUIDE POLYACETAL 6 GUIDE RING POLYACETAL 7 PISTON O-RING NITRILE 8 FLANGE AISI 316L 9 SCREW AISI 304 10 SEAT SILICON DIMENSIONS (MM) OPPROX. AIR CONSUMP- VALVE MODEL NUMBER TIME TION IN LTR WT. OF SIZE Cv ASSY A B C D E F G H I J K L OPEN CLOSE TO TO IN KGS. (SEC.) (SEC.) OPEN CLOSE 1267/25/IL/AISI316L/AISI316L/DAW 22.22 75.00 84.82 143.5 109.00 8.00 7.5 20.00 85.00 169.82 79.24 209.44 22 0.2 0.2 0.075 0.05 1.41 25 1267/25/IL/AISI316L/AISI316L/SAW 22.22 75.00 84.82 143.5 109.00 8.00 7.5 20.00 85.00 169.82 79.24 209.44 22 0.3 0.3 0.075 1.56 1267/25/IL/AISI316L/AISI316L/DAW 34.92 75.00 87.36 143.5 109.00 8.00 7.5 20.00 85.00 172.36 84.83 214.77 80 0.2 0.2 0.075 0.05 1.47 40 1267/25/IL/AISI316L/AISI316L/SAW 34.92 75.00 87.36 143.5 109.00 8.00 7.5 20.00 85.00 172.36 84.83 214.77 80 0.3 0.3 0.075 1.62 1267/25/IL/AISI316L/AISI316L/DA00 47.62 85.72 97.52 160.00 125.00 10.00 11.00 30.00 110.00 207.52 104.64 259.84 195 0.3 0.3 0.15 0.1 3.78 50 1267/25/IL/AISI316L/AISI316L/SA00 47.62 85.72 97.52 160.00 125.00 10.00 11.00 30.00 110.00 207.52 104.64 259.84 195 0.4 0.4 0.15 2.93 1267/25/IL/AISI316L/AISI316L/DA00 60.32 84.12 101.85 160.00 125.00 10.00 11.00 30.00 110.00 211.85 111.76 268.73 250 0.3 0.3 0.15 0.1 4.26 65 1267/25/IL/AISI316L/AISI316L/SA05 60.32 84.12 101.85 160.00 125.00 10.00 11.00 30.00 110.00 211.85 111.76 268.73 250 0.4 0.4 0.15 4.46 1267/25/IL/AISI316L/AISI316L/DA05 72.61 92.07 107.95 194.00 146.00 10.00 11.00 30.00 122.00 229.95 124.46 292.18 400 0.4 0.4 0.28 0.25 3.9 80 1267/25/IL/AISI316L/AISI316L/SA05 72.61 92.07 107.95 194.00 146.00 10.00 11.00 30.00 122.00 229.95 124.46 292.18 400 0.4 0.4 0.15 4.7 1267/25/IL/AISI316L/AISI316L/DA05 97.61 109.93 124.61 194.00 146.00 10.00 11.00 30.00 122.00 246.91 156.97 325.09 840 0.4 0.4 0.28 0.25 5.7 100 1267/25/IL/AISI316L/AISI316L/SA10 97.61 109.93 124.61 194.00 146.00 10.00 11.00 30.00 122.00 246.91 156.97 325.09 840 0.5 0.5 0.28 6.78 1267/25/IL/AISI316L/AISI316L/DA10 121.43 113.48 149.86 236.00 182.00 10.00 11.00 30.00 127.00 276.86 180.08 366.9 1200 0.5 0.5 0.33 0.32 8.11 125 1267/25/IL/AISI316L/AISI316L/SA15 121.43 113.48 149.86 236.00 182.00 10.00 11.00 30.00 127.00 276.86 180.08 366.9 1200 0.6 0.6 0.33 10.19 1267/25/IL/AISI316L/AISI316L/DA15 146.83 113.48 165.86 266.00 203.00 10.00 11.00 30.00 148.00 313.86 211.83 419.77 1900 0.8 0.8 0.8 0.7 9.8 150 1267/25/IL/AISI316L/AISI316L/SA20 146.83 113.48 165.86 266.00 203.00 10.00 11.00 30.00 148.00 313.86 211.83 419.77 1900 1 1 0.8 12.96 1267/25/IL/AISI316L/AISI316L/DA20 200.02 113.48 187.96 312.00 234.00 16.00 11.00 30.00 161.00 348.96 256.28 477.1 3200 1 1 1.5 1.2 13.41 200 1267/25/IL/AISI316L/AISI316L/SA25 200.02 113.48 187.96 312.00 234.00 16.00 11.00 30.00 161.00 348.96 256.28 477.1 3200 1.6 1.6 1.5 0.7 19.04 19 1257/1267/1357/1367SERIES SUDE

- 21. Butt-Weld Metalic Ball Valve with Single Phase Electrical Actuator 1357 E F 1 M 2 3 H G 5 J K I N 4 L 10 7 8 D C B 9 A 6 BILL OF MATERIAL OF VALVE WITH ACTUATOR S.No. PART MATERIALS 1 ELECTRIC ACTUATOR STAY PUT TYPE 2 MOTOR 3 HAND WHEEL SDTORK MAKE 4 OUTPUT BORE 5 CABLE GLANDS 6 BODY AISI316L 7 FLANGE AISI316L 8 CAP SCREW AISI 304 9 O-RING EPDM 10 SEAT TFM PTFE DIMENSION (MM) APPROX. VALVE MODEL NUMBER TIME WT. OF SIZE Cv ASSY A B C D E F G H I J K L M N FOR FOR IN KGS. OPEN CLOSE 25 1357/25/BW/AISI316L/AISI316L/SD-1000-03 94.05 34.13 22.22 72.23 68 117 175 247.2 281.36 100 110 145 215 32 17.00 17.00 66 9.70 40 1357/40/BW/AISI316L/AISI316L/SD-1000-03 107.15 41.27 34.92 81.35 68 117 175 256.3 297.62 100 110 160 215 32 17.00 17.00 192 9.90 50 1357/50/BW/AISI316L/AISI316L/SD-1000-05 117.07 49.21 47.62 98.42 68 117 175 273.4 322.63 100 110 160 225 32 17.00 17.00 434 11.60 65 1357/65/BW/AISI316L/AISI316L/SD-1000-05 135.73 59.53 60.32 107.15 95 148 250 357.1 416.68 100 110 170 225 37 20.00 20.00 723 13.60 80 1357/80/BW/AISI316L/AISI316L/SD-1000-10 157.95 65.88 72.62 114.3 95 148 250 364.3 430.18 100 110 185 285 37 20.00 20.00 1124 20.50 100 1357/100/BW/AISI316L/AISI316L/SD-1000-10 170.25 86.91 97.63 127.00 123 182 261 388.0 474.91 100 110 242 355 57 20.00 20.00 2100 26.50 SUDE 1257/1267/1357/1367SERIES 20