Em baixo de uma arvore instruções

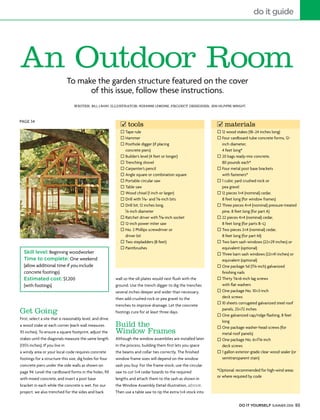

- 1. do it guide An Outdoor Room To make the garden structure featured on the cover of this issue, follow these instructions. WRiteR: Bill lahay. illustRAtOR: Roxanne lemoine. PROject designeR: Jeni hilpipRe-wRight. PAge 34 ¸ tools ¸ materials ® rule Tape ® wood stakes (18–24 inches long) 12 Hammer ® ® cardboard tube concrete forms, 12- Four Posthole digger (if placing ® inch diameter, concrete piers) 4 feet long* Builder’s level (4 feet or longer) ® ® bags ready-mix concrete, 20 Trenching shovel ® 80 pounds each* Carpenter’s pencil ® ® metal post base brackets Four Angle square or combination square ® with fasteners* Portable circular saw ® 1 cubic yard crushed rock or ® Table saw ® pea gravel Wood chisel (1 inch or larger) ® ® pieces 1×4 (nominal) cedar, 12 ® with 3⁄16- and 3⁄8 -inch bits Drill 8 feet long (for window frames) ® bit, 12 inches long, Drill Three pieces 4×4 (nominal) pressure-treated ® ⁄ -inch diameter 1 4 pine, 8 feet long (for part A) Ratchet driver with 9 16-inch socket ® ⁄ ® pieces 4×4 (nominal) cedar, 22 12-inch power miter saw ® 8 feet long (for parts B–L) ® 2 Phillips screwdriver or No. ® pieces 2×4 (nominal) cedar, Two driver bit 8 feet long (for part M) ® stepladders (8 feet) Two ® barn sash windows (22×29 inches) or Two Paintbrushes ® equivalent (optional) Skill level: Beginning woodworker Three barn sash windows (22×41 inches) or ® Time to complete: One weekend equivalent (optional) (allow additional time if you include ® package 5d (1 3⁄ -inch) galvanized One 4 concrete footings) finishing nails Estimated cost: $1,200 wall so the sill plates would nest flush with the Thirty 3⁄8×6-inch lag screws ® (with footings) ground. Use the trench digger to dig the trenches with flat washers several inches deeper and wider than necessary, ® package No. 10×3-inch One then add crushed rock or pea gravel to the deck screws ® sheets corrugated galvanized steel roof 10 trenches to improve drainage. Let the concrete get going footings cure for at least three days. panels, 25×72 inches ® galvanized cap/ridge flashing, 8 feet One First, select a site that is reasonably level, and drive long a wood stake at each corner (each wall measures Build the ® package washer-head screws (for One 93 inches). To ensure a square footprint, adjust the Window Frames metal roof panels) stakes until the diagonals measure the same length Although the window assemblies are installed later ® package No. 6×1 5⁄8 -inch One (131⁄2 inches). If you live in 1 in the process, building them first lets you space deck screws a windy area or your local code requires concrete the beams and collar ties correctly. The finished 1 gallon exterior-grade clear wood sealer (or ® footings for a structure this size, dig holes for four window frame sizes will depend on the window semitransparent stain) concrete piers under the side walls as shown on sash you buy. For the frame stock, use the circular page 94. Level the cardboard forms in the holes, fill saw to cut 1×4 cedar boards to the required *Optional: recommended for high-wind areas or where required by code with mixed concrete, and insert a post base lengths and attach them to the sash as shown in bracket in each while the concrete is wet. For our the Window Assembly Detail illustration, above. project, we also trenched for the sides and back Then use a table saw to rip the extra 1×4 stock into DO IT YOURSELF SUMMeR 2006 93

- 2. do it guide An Outdoor Room Preformed/galvanized 1x4" cedar Wood frame cap/ridge flashing barn sash Preformed/galvanized 5d finishing nails cap/ridge flashing Corrugated/galvanized K roofing panels (6' long) Corrugated/galvanized G F K roofing panels J #6 x 15/8" 3/8" lag screws long) (6' GH F deck screw 6" long K M L J 3/8" lag screws 6" long J K H H M L J L H F F E D F D L F 3" deck screws E D B D 3/4 x 3/4" 3" deck screws F B cedar molding B D D F 45 bevelo 45o WINDOW ASSEMBLY DETAIL Window frame of on part M B 1 x 4" cedar M D o D 45 bevel 1 1 /2 " M 45o Window frame of B on part M M ROOF1ASSEMBLY x 4" cedar 11/2" 3M2" 1/ B END VIEW DETAIL ROOF ASSEMBLY 1 3 /2" END VIEW DETAIL No. 10 x 3" deck screws to secure half-lap corner joints ⁄ -inch molding strips and attach them as shown, 3 4 No. 10 x 3" deck screws to secure half-lap corner joints using 5d finishing nails. Set aside for now. D D D D D D cut and Assemble C the Wall Frames C D D Start by cutting the sill plates (A) to length; Half-laps C because they rest directly on C Half-laps the ground, these timbers should be pressure- B C lag screw3/8" 6" long at treated pine rated for ground-contact use. Then B corner posts 3/8" lag screwcut the other frame parts (B–D) to length. For the C B 6" long at top wall plates (D), mark the half-lap notches as B C corner posts shown in the Half-Lap Joint Detail illustration, B B C opposite, and use the portable circular saw to Window frames B C make multiple cuts in the notch portion. Break (1x4" cedar) C away the waste material with a hammer, then use a Window frames B chisel to pare the surface flat and smooth. Note A (1x4" cedar) C A that these end notches are the same for all four A top plates, but are oriented differently—set the C A front and rear plates with the notch faceup and Post-base bracket the side plates with the notch facedown. 3/8" lag screw A embedded 6" long at corners in concrete pier On each corner post (B), mark the locations for Post-base bracket 3/8" lag screw A embedded the sill plates (A) and crossbeams (C). The vertical 6" long at corners in concrete pier distance between the two beams should equal the BASE / WALL ASSEMBLIES Concrete pier footing height of the taller window assemblies. On a flat BASENote: Concrete piers optional. / WALL ASSEMBLIES (12" diameter) surface, such as a patio or driveway, fit together Concrete pier footing parts A–C of one side wall. Use the 12-inch-long (12" diameter) Note: Concrete piers optional. 94 DO IT YOURSELF SUMMeR 2006

- 3. [a] [B] [C] [D] [E] [F] [G] [H] [J] [K] [L] [M] PaRTS Sill Plates Corner Posts Cross- beams Top Wall Plates Center Beam Rafters Ridge Beam Purlins Collar Ties Ridge Blocks Roof Braces Beveled Roof Plates THICKnESS 3⁄2 1 3⁄2 1 3⁄2 1 3⁄2 1 3⁄2 1 3⁄2 1 3⁄2 1 3⁄2 1 3⁄2 1 3⁄2 1 3⁄2 1 1⁄2 1 WIDTH 3⁄2 1 3⁄2 1 3⁄2 1 3⁄2 1 3⁄2 1 3⁄2 1 3⁄2 1 3⁄2 1 3⁄2 1 3⁄2 1 3⁄2 1 3⁄2 1 LEnGTH 86 84 86 93 86 67 86 86 25* 10* 60 86 QUanTITY 3 4 6 4 1 4 1 2 2 2 2 2 Notes: All dimensions are in inches. *Lengths may vary; cut to fit. HALF-LAP JOINT DETAIL work in stages so you can test-fit the pieces as you edge, with a slight overhang and with its top edge Make multiple saw cuts 13/4" deep go. Start by attaching the center beam (e) to the slightly below the peak of the ridge beam. Attach front and rear top plates (D) with lag screws, just as with washer-head screws. Overlap the next panel 13 / 4 " you connected the wall crossbeams to the posts. at least one full ridge, and fasten. Repeat to install Step 1 31/2" Next, use the power miter saw to cut four the remaining roof panels, then attach the cap rafters (F) with 45-degree miters at the base ends; flashing along the ridge. leave the opposite ends To install the window assemblies, simply fit Step 2 a few inches longer than listed. With a helper, set them into place and drive 1 5⁄8 -inch deck screws Break away two rafters up at the front gable end, with their through the 1×4 stock into the crossbeams, top waste pieces angled ends placed at the corners and the upper wall plates, and/or collar ties. ß Pare smooth with chisel ends slightly offset so they bypass each other. Step 3 Mark each rafter end along the upper edge of the opposing rafter, then square-cut those ends and cut half-lap notches as shown, similar to the top drill bit to drill a ⁄ -inch hole through 1 4 wall plate ends. Refit and attach with 3-inch deck the posts and into the beam/sill ends at each joint screws to the top wall plate corners as shown. as shown. Then switch to a Repeat for the rear rafters. With all the rafters in ⁄8 -inch bit and enlarge only the holes in the posts. 3 place, fit and attach the ridge beam (g) and the Tap a ⁄8×6-inch lag screw 3 purlins (H) with lag screws as shown. into each hole until it seats firmly, then tighten Using the smaller window assemblies for with a ratchet driver. (Use this technique on the spacing, cut and fit the collar ties (J) into the end roof frame joints, too.) gables as shown; attach with 3-inch deck screws. Set some scrap blocks of wood across the wall Then cut and attach the two ridge blocks (K) the trenches, then recruit a helper to lift the first wall same way. Finally, cut a 45-degree miter on one assembly into position; use ground stakes and end of each roof brace (L) and do a test fit to mark temporary braces to stabilize it. Repeat for the the lower end; cut to fit, and attach with lag screws second wall section, then use more lag screws to as shown. connect the two walls with the rear sill and beams, With the frame complete, apply a coat of creating a U-shape structure. With at least two exterior-grade clear sealer or semitransparent stain helpers, remove the scrap blocks from the if desired. trenches and lower the frame assembly into place; check for level, plumb, and square, and attach the install Roofing sills to the post base brackets in the concrete and Windows footings. Use 3-inch deck screws to attach the top Use the table saw to rip two cedar 2×4s with a 45- wall plates (D). Backfill the trenches with gravel. degree bevel cut to make the roof plates (M); use 3-inch deck screws to attach them to the top wall cut and Assemble plates, with the bevel facing out and aligned with the Roof Frame the rafters as shown. Starting at one end, place a Rather than precut all the parts for the roof frame, corrugated metal roofing panel along the rafter www.diyideas.com DO IT YOURSELF SUMMeR 2006 95