AMS® CAT BOSS™ Cleaner Procedure

•

0 gostou•275 visualizações

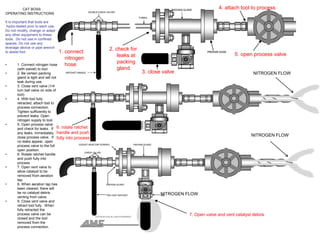

The document provides operating instructions for a CAT BOSS tool. It outlines 9 steps to connect the nitrogen hose, check for leaks, attach the tool to the process connection, open the process valve while monitoring for leaks, insert the tool fully into the process, vent catalyst debris from the aeration tap, and then retract and remove the tool from the process connection.

Denunciar

Compartilhar

Denunciar

Compartilhar

Baixar para ler offline

Recomendados

Recomendados

Mais conteúdo relacionado

Destaque

Destaque (13)

Reuben osborn lax a2 pre production tasks feedback sheet

Reuben osborn lax a2 pre production tasks feedback sheet

Feed back form for teaching faculty in PG colleges

Feed back form for teaching faculty in PG colleges

Semelhante a AMS® CAT BOSS™ Cleaner Procedure

Semelhante a AMS® CAT BOSS™ Cleaner Procedure (18)

Manual de-instalacao-e-manutencao-de-valvula-gaveta-aco-fundido

Manual de-instalacao-e-manutencao-de-valvula-gaveta-aco-fundido

Eureka Upright Vacuum Cleaner Owner's Guide- 4870 Series

Eureka Upright Vacuum Cleaner Owner's Guide- 4870 Series

Dome valve operation manual for ash handling system .pdf

Dome valve operation manual for ash handling system .pdf

CHANGING OUT DUST BAGS IN REVERSE PULSE DUST COLLECTORS

CHANGING OUT DUST BAGS IN REVERSE PULSE DUST COLLECTORS

Mais de Arthur Doty

Mais de Arthur Doty (14)

SafetyWedge® (publication) Safer flange spreading tools

SafetyWedge® (publication) Safer flange spreading tools

AMS® CAT BOSS™ Cleaner Procedure

- 1. CAT BOSS 4. attach tool to process OPERATING INSTRUCTIONS It is important that tools are hydro-tested prior to each use. Do not modify, change or adapt any other equipment to these tools. Do not use in confined spaces. Do not use any leverage device or pipe wrench 2. check for to assist tool. 1. connect leaks at 5. open process valve nitrogen packing • 1. Connect nitrogen hose hose (with swivel) to tool. gland • 2. Be certain packing 3. close valve NITROGEN FLOW gland is tight and will not leak during use. • 3. Close vent valve (1/4 turn ball valve on side of tool) • 4. With tool fully retracted, attach tool to process connection. Tighten sufficiently to prevent leaks. Open nitrogen supply to tool. • 5. Open process valve and check for leaks. If 6. rotate ratchet any leaks, immediately handle and push close process valve. If fully into process NITROGEN FLOW no leaks appear, open process valve to the full open position. • 6. Rotate ratchet handle and push fully into process • 7. Open vent valve to allow catalyst to be removed from aeration tap. • 8. When aeration tap has been cleared, there will be no catalyst debris NITROGEN FLOW venting from valve. • 9. Close vent valve and retract tool fully. When fully retracted the process valve can be 7. Open valve and vent catalyst debris closed and the tool removed from the process connection.