Corrosion

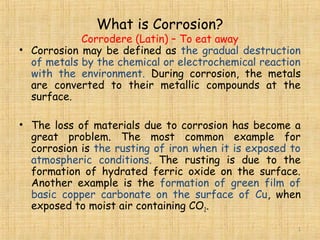

- 1. What is Corrosion? Corrodere (Latin) – To eat away • Corrosion may be defined as the gradual destruction of metals by the chemical or electrochemical reaction with the environment. During corrosion, the metals are converted to their metallic compounds at the surface. • The loss of materials due to corrosion has become a great problem. The most common example for corrosion is the rusting of iron when it is exposed to atmospheric conditions. The rusting is due to the formation of hydrated ferric oxide on the surface. Another example is the formation of green film of basic copper carbonate on the surface of Cu, when exposed to moist air containing CO2. 11

- 2. Why study Corrosion? 2 1. Materials are Precious resources 2. Engineering design is incomplete without knowledge of corrosion 3. Applying knowledge of corrosion protection can minimize disasters 4. Corrosion- may contaminate stored food, dairy products , etc 5. Corrosion products cause pollution 6. Artificial implants for the human body ? 2

- 3. Types of Corrosion 3 1. Direct Chemical Corrosion or Dry Corrosion This type of corrosion occurs mainly through the direct chemical action of atmospheric gases such as O2, halogens, H2S, CO2, SO2, N2, H2 or liquid metals on metal surface in the absence of moisture. 2. Electrochemical Corrosion or Wet Corrosion This type of corrosion occurs when : a. A metal is in contact with a conducting liquid b.Two dissimilar metals or alloys are immersed partially in a conducting solution. This corrosion is due to the existence of separate anodic and cathodic areas between which current flows through the conducting solution. 3

- 4. Direct Chemical Corrosion or Dry Corrosion 4 and other gases 44

- 5. 5 According to electrochemical theory, corrosion of metals occurs due to the following changes, when they are exposed to the environment. 1) A large number of minute galvanic cells are formed which acts as anodic and cathodic areas. 2) At anode the metal undergoes oxidation and electrons are liberated which migrates towards cathodic region 3) Oxygen of the atmosphere undergoes reduction at cathodic area in the presence of moisture forming hydroxyl ions at the cathode. Electrochemical Corrosion or Wet Corrosion 5

- 6. Types of Electrochemical Corrosion 6 1. Galvanic corrosion or Bimetallic corrosion When two dissimilar metals or alloys are electrically connected and exposed to an electrolyte, the metal higher in electrochemical series under goes corrosion. Thus when Zn and Cu are connected, Zn being higher in the series act as anode and undergoes corrosion and Cu which is lower in the series act as cathode and gets protected. Ex: Steel pipe connected to copper plumbing and Lead – antimony solder around copper wire. 66

- 7. Pitting Corrosion 7 Pitting corrosion is a localized accelerated attack resulting in the formation of pin holes, pits and cavities on the metal surface. It is due to the breakdown or cracking of the protective film on the metal at specified points. This gives rise to the formation of small anodic and large cathodic areas. Once a small pit is formed the rate of corrosion will be increased. Presence of external impurities like sand, dust, water drops etc on the surface of the metal can also be a cause for this type of corrosion. In this case, the small part below the impurity acts as the anodic area while the rest of the metal acts as the cathode area. Due to corrosion a small pit is formed at the anodic area which grows gradually.

- 8. Concentration Cell Corrosion 8 This type of corrosion is due to electrochemical attack on the metal surface exposed to an electrolyte of varying concentrations. Metal in contact with lower concentration will act as anode and undergoes corrosion. It is observed in chemical plants and storage tanks and also in marine structures like ships. Differential aeration corrosion is the most important. 88

- 9. Water Line Corrosion 9 It is another type of differential aeration corrosion. Corrosion in storage tanks, H2O tanks, marine structures etc is called water line corrosion. When water is stored in an iron tank, it is found that maximum corrosion occurs along a line just below the water level. The area above the H2O line is highly oxygenated and acts as cathode while the area just below the H2O line is less oxygenated and acts as anode and undergoes corrosion. 9 9

- 10. 10 The important methods used to control corrosion are, 1.Design and selection of the materials. 2. Protective coatings. a) Organic coatings – paints and enamels. b) Inorganic coatings i) Metal coatings – anodic and cathodic ii) Surface conversion coatings – anodizing, phosphating. 3) Corrosion inhibitors. 4) Cathodic protection. 5) Anodic protection. Corrosion Control or Protection from Corrosion 1010

- 11. Inorganic Coatings 11 i) Metal coatings – anodic and Cathodic ii) Surface conversion coatings – anodizing, phosphating. i) Metal coatings Deposition of protective metal over the surface of base metal(metal to be procted from corrosion) is known as metallic coatings. It is divided into Anodic and Cathodic metal coatings. a) Anodic metal coatings: Anodic metal coatings involve coating the base metal with more active metals, which are anodic to the base metal. Example: Galvanization b) Cathodic coatings: Cathodic coatings involve coating a base metal with more noble metals, which are cathodic to the base metal. Metals such as Copper, Nickel, Tin, and Silver etc are coated on Iron. One of the disadvantage of Cathodic coatings is if coating ruptures it leads more corrosion because of small anodic area and large cathodic area. Example: Tinning

- 12. Surface Conversion Coatings 12 Surface conversion coatings are chemical conversion coatings. The surface layer of the base metal is converted into a compound by chemical or electrochemical reactions, which prevents the base metal form corrosion. The coating can be done by chemical dip, spray or by electrolytic method. The coating helps in the increased electrical insulation, enhanced adherence for paints and prevention of corrosion. Example: Anodizing , Phosphating 1212

- 13. Explain the Process of Galvanization 13 It is a process of coating the base metal surface with Zinc, tin, lead, or aluminium metal. Example: coating Zinc on Iron by hot dipping Method. It involves the following steps. • The Iron metal surface is washed with organic solvents to remove oil, grease etc content on the metal surface. • Then the metal is passed through dilute sulphuric acid to remove rust and other depositions. Finally the metal is washed with water and dried. • The metal is then dipped in molten Zinc and passed through Ammonium chloride and Zinc chloride flux to prevent oxidation of Zinc. The excess Zinc is removed by passing through the rollers or by wiping. • Uses: Galvanisation is used for roofing sheets, buckets, bolts, nuts, nails, pipes etc.

- 14. 14 Explain the Process of Tinning Tinning is a process of coating the base metal with Tin (Sn). It is carried out by hot dipping method as fallows. • The base metal surface is washed with organic solvents to remove oil, grease etc content on the metal surface. • Then the metal is passed through dilute sulphuric acid to remove rust and other depositions. Finally the metal is washed with water and dried. • The metal is passed through Ammonium chloride and Zinc chloride flux and then dipped in molten Tin. Finally it is dipped in palm oil to prevent oxidation of Tin. The excess Tin is removed by passing through the rollers or by wiping. Tinning is widely used for coating steel, Cu and brass sheets which are used for making containers for storing food studs, oils, kerosene & packing food materials. Tinned Cu sheets are used for making cooking utensils & refrigeration equipments.

- 15. Corrosion Control or Protection from Corrosion 15 Cathodic Protection In this method, the corroding metal is forced to behave like a cathode. There are two types of cathodic protection. a. Sacrificial Anodic protection on Galvanic protection In this method, the metallic structure which is to be protected from corrosion is connected to a more anodic metal by a wire so that the entire corrosion is concentrated on this more active metal. The more active metal loses electrons and get corroded and this metal is called sacrificial anode. Metals commonly employed as sacrificial anode are Mg, Zn, Al and their alloys. 1515

- 16. Sacrificial Anodic protection on Galvanic protection 16 Applications Important applications of sacrificial anodic method include protection of buried pipe lines, underground cables, marine structures etc. 16

- 17. Impressed Current Cathodic Protection 17 In this method, an impressed current is applied in the opposite direction to nullify corrosion current so as to convert the corroding metal from anode to cathode. Impressed current can be derived from a direct current source like battery. An inert or insoluble electrode like graphite or silica act as anode to complete the circuit. The surroundings of anode should be filled with salts and carbon to increased the conductivity. Applications This type of cathodic protection has been applied to water coolers, water tanks, buried oil and water pipes, transmission towers etc. 17

- 18. Use of Corrosion Inhibitors 18 Chemicals which are added in small quantities to the corroding medium in order to reduce the corrosion rate are called corrosion inhibitors. They reduce corrosion by forming a protective film either at the cathode or anode. Thus there are two types of corrosion inhibitors – anodic inhibitors and cathodic inhibitors. Anodic inhibitors Chromates (CrO4), phosphate (PO4), and Tungstates (WO4) transition metals are used as anodic inhibitors. They react with the newly produced metal ions at the anode forming a protective film or barrier there by preventing further corrosion. 1818

- 19. 19 Cathodic Inhibitors These are the substance, which slow down the cathodic reaction. The cathodic reactions involve liberation of hydrogen in acidic solution or OH-ions in alkaline and neutral medium. The cathodic organic inhibitors include amines, thiourea, sulphoxides etc. The two types of cathodic inhibition reactions are liberation of hydrogen, absorption of oxygen and formation of hydroxyl ions. i)Inhibition of Oxygen absorption and Hydroxyl ions ii)Inhibition of Hydrogen liberation Use of Corrosion Inhibitors 19

- 20. Cathodic Inhibitors i) Inhibition of oxygen absorption and hydroxyl ions H2O + ½ O2 + 2 e- 2 OH- The formation of OH- ions can be prevented either by removing O2 from the medium or by decreasing the diffusion of O2 in to the cathode. O2 is removed either by adding reducing agents like Na2 SO3, N2H4 etc or by mechanical dearation. O2 + NH2 – NH2 N2 + 2H2O 2 Na2 SO3 + O2 2Na2SO4 Salts of Zn, Mg or Ni are added to the corroding medium to reduce the diffusion of O2 towards cathode. These salts react with OH- ions at the cathode forming insoluble hydroxides which are adsorbed at the cathode. 2020

- 21. 21 Cathodic Inhibitors ii) Inhibition of Hydrogen Liberation 2H+ + 2 e- H2 (g) Evolution of H2 can be prevented by slowing down the diffusion of H+ ions to the cathode or by increasing H2 over voltage. Diffusion of H+ ions can be prevented by adding organic inhibitors such as amines, urea, thiourea etc. These are adsorbed at the surface as a film. Arsenic oxide or antimony oxide is added to increase the H2 over voltage. These oxides form adherent film of metallic arsenic or antimony at the cathodic areas. 21