Watervliet Arsenal Newsletter: The Salvo 28 February 2014

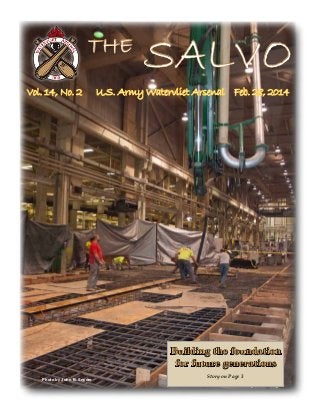

- 1. THE Vol. 14, No. 2 SALVO U.S. Army Watervliet Arsenal Feb. 28, 2014 Building the foundation for future generations Photo by John B. Snyder Story on Page 3 Photo by John B. Snyder

- 2. Page 2 Salvo Feb. 28, 2014 Commander’s Corner You probably have seen the recent news in local newspapers and in the Salvo about multimillion dollar orders that seem to be coming back to the arsenal after a rather dry period due to sequestration or what is known in the Defense Department as fiscal uncertainty. Although that is good news, we must temper that news with a dose of reality. The affects of sequestration still loom and there continues to be uncertainty in future defense spending. In addition to significant reductions to the DOD budget, which directly affects weapon program managers’ ability to fund new contracts, our hiring authority and use of overtime/compensation time remains restricted. I often see on our social media pages comments from former workers who ask why we are not hiring them back if larger orders are flowing in again. The fact is that today’s orders are nowhere near the size of orders that we had just two or three years ago. We, therefore, remain challenged to receive enough workload to ensure that our current, critical skill base will not further erode. In the next two months, we are hosting a variety of weapon program managers, as well as several Army senior leaders, to discuss workload. You can be assured that I and other arsenal leaders will speak volumes about the importance and value that we have Commander, Col. Lee H. Schiller Jr. Public Affairs Officer, John B. Snyder Editor, John B. Snyder Photographer: John B. Snyder Arsenal Facebook Page @ http://on.fb.me/sq3LEm to the community, state, and to our nation. And, we will aggressively seek any order, for any machined product, no matter the size of the order. At the end of the day, work is work and we need more of it to maintain our sills and remain cost effective. In preparation for the upcoming visits, please take a look around your areas of operation. If there was ever a time to clean up and make our areas safer, now is that time. First impressions are critical. A visual of our manufacturing operations will far outweigh anything we brief on a PowerPoint slide. Speaking of safety, we still have about six more weeks of extreme cold weather. There are coldweather dangers all around us, on the ground and above our heads. Please remain observant of your environment as you move in and about the arsenal. Lee H. Schiller Jr. Commanding Manufacturer 6 The Arsenal Salvo is an authorized monthly publication for members of the Department of Defense. Contents of the Salvo are not necessarily the official views of, or an endorsement by the U.S. Government, the Department of Defense, the Department of the Army, or the Watervliet Arsenal. News may be submitted for publication by sending articles to Public Affairs Officer, 1 Buffington Street, Bldg. 10, Watervliet, NY 12189, or stop by office #102, Bldg. 10, Watervliet Arsenal. The editor may also be reached at (518) 266-5055 or by e-mail: john.b.snyder.civ@mail.mil. The editor reserves the right to edit all information submitted for publication.

- 3. Page 3 Salvo Feb. 28, 2014 Trying to fill the gaps Photo by John B. Snyder Scott Evertsen, an arsenal mechanical and controls designer, stands by the foundation work that he is overseeing. More than 1.3 million pounds of concrete was needed to fill this hole. This work supports arsenal efforts to bring on line $26 million in new machines and machine upgrades this fiscal year. By John B. Snyder Just a few years ago, the Watervliet Arsenal’s control over its information flow regarding manufacturing operations was just as tight as the Wizard of Oz had behind his curtain. No news releases went out and media were not invited in. What was being manufactured was for the most part unknown, even to the local community who lived just outside the arsenal fence line. But even the Great Oz was revealed and so, it was just a matter of time before Watervliet’s operations would also be known to the world. The days of orders freely flowing in to support combat operations to two wars have been on a downward slope since 2011. In 2011, the arsenal had more than $120 million in sales that ranged from guns for Abrams tanks to 120-mm mortar tubes. For fiscal year 2013, revenue dropped to about $96 million. The fact that orders have slowed is not news to the workforce. After all, the arsenal’s history book is rich with the stories of the arsenal having survived the ebbs and flows of military orders that have taken place after every military conflict since the War of 1812. Nevertheless, what today’s workforce may be really concerned about is how to maintain an adequate level of workload so that the arsenal’s cost rates do not spike up. When workload falls, rates go up due in large part to fixed costs that are difficult to control. If the arsenal’s products become too expensive, then prospective buyers from the Defense Department and from private industry will be less likely to consider the arsenal for their manufacturing needs. The bottom line is that lower workload has a direct correlation to a smaller workforce and that may be at the crux of today’s workforce concerns. Since the beginning of fiscal 2013, the arsenal workforce numbers have fallen by about 10 percent to about 545 personnel today. Story continues on page 4, Equipment

- 4. Page 4 Salvo Feb. 28, 2014 Equipment Cont. Fiscal tools, such as reducing the size of the workforce, a hiring freeze, and a very restrictive use of overtime, have helped reduced operation costs in fiscal year 2013 by more than $12 million. But those actions are only part of the equation that arsenal leadership sees as the answer to remaining relevant and competitive. In one of the production bays, in a building that was built during World War I, there is a hub of activity and we are not talking about machining. This is ground zero on a major modernization of the arsenal’s manufacturing center. “Within fiscal year 2014, we plan to bring on line more than $26 million in new machines and enhanced capabilities,” said Jim Kardas, the leader of the arsenal’s Manufacturing Engineering Group. “This new equipment will allow us to benefit from modern technologies, such as superior control systems and faster machining speeds, which may lead to significantly reducing machining time.” The new machines can perform multiple operations, whereas the former machines may have been able to perform only one operation. Photo by John B. Snyder There is an art and science to how the arsenal brings in and sets up new equipment. Photo by John B. Snyder The arsenal is trying to shift more focus and resources toward business development. As part of this effort, the arsenal hosted this month Troy Record newspaper reporter Danielle Sanzone, right, to help tell this story. Her story made it to page one of her newspaper. But what may be one of the greatest advantages to bringing on line new, enhanced capability is not so much what those machines will do for arsenal products, but what they may do for private industry. “The Army leadership directed the Army’s Industrial Base to seek out public-private partnerships to help arsenals and depots to remain relevant, effective, and efficient,” said Ray Gaston, the arsenal’s chief of the Production Planning and Control Division. “We have a billion dollar investment in capability, as well as thousands of years of machining experience, that may be leveraged by private industry to support their operations.” There is no limit to what may be machined at the arsenal. From something as small that can fit into one’s pocket to a 30-foot cylindrical tube can be produced at Watervliet, Gaston said. “So, before a manufacturer or a startup company invests time and money into bringing on line a manufacturing capability, they should first consider the arsenal’s vast manufacturing capability in machines, tooling, and in machining experience,” Gaston said. This is a win-win situation in that the arsenal will retain critical skills, as well as reduce its cost of operation by entering into a public-private partnership. Private industry may save time and money because they will not need to invest in capability in regards to equipment and personnel that is readily available at Watervliet. The Great Oz actually turned out to be a pretty nice guy once he stepped out from behind the curtain. The Watervliet Arsenal has also stepped out from behind its veil and believes that private industry will find its workforce pretty good people to work with, too.

- 5. Page 5 Salvo Feb. 28, 2014 Small orders add up ... to the tune of $10.9M By John B. Snyder The Watervliet Arsenal announced this month that it vate industry. And with the war in Iraq having ended and combat operation in Afghanistan soon to end, this is received nine contracts worth more than $10.9 million a very competitive time for those companies that supply to provide various weapon system components for the the defense industrial base. U.S. Army’s TACOM Life Cycle Management ComThe bottom line is that whatever the arsenal can do mand. These items will go to sustain U.S. troop units in to hold the line on its operating expenses helps it remain the field. competitive. But there is only so much cost containThese orders add to the arsenal’s current workload ment that can be done without causmore than 19,000 direct labor hours ing irreversible damage to its infrafor fiscal years 2014 and 2015, said structure and skill base and therefore, Ray Gaston, the arsenal’s chief of the best way to reduce its cost of the Production Planning and Control production is by having a healthy Division. workload. “This is huge for us,” Gaston said. Nevertheless, the arsenal has been “Although these orders will not make doing all that it can to slow down up for all the workload we have lost potential hikes to its cost rates. For the past 12 months due to sequestrathe fiscal year that ended last Seption, they represent the most sigtember, the arsenal reduced its cost nificant amount of new work that we of operations by more than $12 milhave seen in the last six months.” lion by implementing such actions as When sequestration took effect in eliminating planned maintenance and March 2013, weapon program manrepair projects and by reducing its agers became hesitant to award new workforce numbers from about 600 contracts because of the fiscal uncerto 560. Arsenal leaders are currently tainty that sequestration caused withimplementing other methods to rein the defense budget, Gaston said. duce this year’s cost of operation by Large multimillion dollar contracts several more millions of dollars. for various weapon systems were not Funny how time and fiscal uncershowing up in future workload proPhoto by John B. Snyder tainty changes the dynamics of the jections for the arsenal, which in turn Arsenal Toolmaker and Apprentice Program Army’s industrial base because just affects cost rates. Supervisor Terry Van Vranken takes a motwo years ago a $1 million contract Cost rates go up when workload ment last month to explain to Times Union would not have raised any eyebrows declines because there is less revphotographer Cindy Schultz that the arsenal at the arsenal. But last month, the enue to cover the fixed and variable manufactures more than just cannons. arsenal’s eyes were not only wide costs associated with maintaining the open when it celebrated a $1 million order for clamps arsenal’s 2.1 million square feet of manufacturing and for the 81 mm mortar system, the story also made headadministrative space. Higher cost rates may then drive lines in the Army. potential customers, the U.S. Defense Department and The arsenal is also looking at how to make up some or defense contractors, away from considering the arseof the potential workload fallout by seeking publicnal as a manufacturing source. But why would an Army arsenal need to worry about private partnerships and by tapping into foreign military sales. In the meantime, the arsenal is celebrating all workload and cost rates? Although the arsenal is an Army-owned and operated contracts, no matter how small. The orders, which range from manufacturing cannon manufacturing center, U.S. defense manufacturing work tubes and bore evacuators for Abrams tanks to breechdoes not automatically flow to the arsenal. The arsenal must compete not only against a handful of other Army block parts for the M777 155 mm lightweight howitzer system, will begin shipping in August 2014. manufacturing centers, it also must compete with pri-

- 6. Salvo Page 6 Feb. 28, 2014 Oh, it has been a busy month Blood Drive 11-12 February About 120 units of blood were collected this month at the Watervliet Arsenal. Just another example of the arsenal workforce giving back to the community. Photo by John B. Snyder Benét Labs Analyst Amy Carson, left, donating blood while Donor Specialist Fiona Lomax prepares to end the draw. Society of Manufacturing Engineers The arsenal takes great pleasure helping to educate fellow manufacturers and manufacturing students about Defense Manufacturing. On February 12, we had the honor to host a local chapter of the Society of Manufacturing Engineers. Photo by John B. Snyder Arsenal Foreman Paul Nieckarz, in rust-colored coat, escorted nearly 30 representatives from the Society of Manufacturing Engineers through several production bays. Four Chaplains Memorial Service and Brotherhood Award Ceremony The arsenal had the pleasure on February 23 to participate in the Four Chaplains Memorial Service at the Stratton VA Medical Center. The service honored four U.S. Army Chaplains, Rev. George Fox, Rabbi Alexander Goode, Rev. Clark Poling, and Father John Washington, who, on the night of Feb. 3, 1943, took off their life jackets and gave them to young Soldiers as the troopship Dorchester was sinking. As part of this memorial service was an award ceremony that honored Mr. Bob Nevins, a former medevac pilot in Vietnam, who in 2010 created the non-profit Saratoga Warhorse Foundation to assist struggling Veterans to adjust to life after military service. Photo by John B. Snyder

- 7. Page 7 Salvo Feb. 28, 2014 CPAC Civilian Personnel Advisory Center What To Do If You Are Injured At Work If you are injured at work, you may be entitled to injury compensation benefits provided under the Federal Employees' Compensation Act (FECA). Federal employees have certain rights and responsibilities in filing for these benefits: Immediately report any work-related injury to your supervisor. If your injury requires medical treatment, obtain care as soon as possible. You have a right to choose your treating physician. To protect your rights to certain benefits, you must notify your supervisor that you would like to file a Workers’ Compensation claim. This is NOT the same process as filing an accident report with the Safety Office. You should file a claim as soon as possible, but not later than 30 days after your injury. To start the process, you and your supervisor will complete one of the following forms using the Electronic Data Interchange (EDI): 1. Form CA-1, Federal Employee's Notice of Traumatic Injury and Claim for Continuation of Pay/Compensation, if your injury results from a specific event or a series of events during one day or shift, or 2. Form CA-2, Federal Employee's Notice of Occupational Disease and Claim for Compensation, if you develop a condition due to prolonged exposure lasting more than one day or shift, Your supervisor will transmit these forms to the Injury Compensation Specialist (ICS). Complete these forms as precisely as possible in order to avoid delays caused by asking you for additional information. You may be asked to provide additional information. Although your supervisor or other agency representative may assist you, it is your responsibility to obtain the information needed to support your claim and to provide it to the ICS. If you are temporarily unable to work because of your injury, you need to keep your supervisor and the ICS informed about your medical condition, and return to work as soon as your physician allows you to do so. Detailed medical documentation will be necessary for your absences to be covered under FECA. Light duty assignments may be available if you are not able to perform your regular job, and if so, you must advise your physician of the availability of such assignments. To protect your rights and receive benefits as quickly as possible, please do not delay in reporting a work-related injury.

- 8. Page 8 Salvo Feb. 28, 2014 Celebrating Diversity More than 150 people attended this year’s Diversity Day Luncheon on February 27. But one of the highlights of this annual gathering was the presentation of the arsenal’s Martin Luther King Award to this year’s recipients, Beth Myers and Al Columbus. Beth has shown her unwavering passion toward diversity at the arsenal in both the work place and in introducing and recommending a diverse selection of contractors to her staff to ensure the Watervliet Arsenal exceeded its targeted small business goals. Al, through his leadership, has invigorated and promoted a climate of respect, confidence and diversity in the Law Enforcement and Security section. Photo by Billy Martin Arsenal History Trivia Why must we maintain critical skill sets after each conflict? A snapshot in arsenal history helps to explain why. When arsenal Commander Col. Alfred Mordecai arrived at the post in 1898, during the Spanish-American War, there were 482 workers. The Arsenal buildings and machines were new, and in good condition. He reported: “The principal and most serious difficulty experienced was the procurement of machinists sufficiently skilled for gun construction. It became necessary to employ men of all grades and of unknown ability and to try all who, from their own statement, might appear at all favorable. Although some 200 workmen were employed in about two months, not over six were found capable of being graded as firstclass machinists.”

- 9. Page 9 Salvo Feb. 28, 2014 Millions of reasons why Dorine LeBlanc is an arsenal Face of Strength Story and photo by John B. Snyder To anyone who has ever managed a household checkbook, they know the degree of difficulty of trying to account for the last few cents that is keeping them from achieving a balanced accounting. Now imagine the degree of difficulty when the account balance has a few more zeros, in this case $117 million worth of zeros. That is what the arsenal’s budget was for fiscal year 2013. Dorine LeBlanc, who is the lead budget analyst for the arsenal, has this awesome challenge as she oversees tens of thousands accounting inputs each year that tell the story of whether the arsenal’s revenue, expenditures, and fiscal health are in balance and if they are not, where the discrepancies may be. If this was simply a matter of tracking the ebb and flow of revenue and expense dollars, then some might think that with today’s technology that this shouldn’t be too hard to manage. But it is more than just that. The $117 million is just a drop in the bucket compared to what Dorine and her team of seven manage. In addition to $117 budget, she and her team oversee all financial requirements for an Army manufacturing center valued at more than $1.6 billion. The arsenal’s 72 buildings and the more than 600 machines have value that must be captured and measured. When one adds in depreciation expenses and capital improvements, this then becomes a task that few would want, let alone have the experience level and or training to manage. Although Dorine says that the Logistics Modernization Program or LMP has given her team fairly good visibility on thousands of records and financial data calculations, the difficulty in trying to make sense of this data requires an “art” to go with the science. Simply being able to enter and extract data is the “science” to financial management. Being able to understand, visualize, and then to explain in layman’s terms what the science means is the “art.” Dorine is able to do both. “What Dorine brings to the arsenal’s financial management team goes beyond simply being extremely professional and dependable,” said Tony Urban, the arsenal’s chief of resource management. “Dorine’s more than 25 years of military experience, coupled with her being one of the architects of the financial modernization program, makes her value to the arsenal nothing less than significant.” By the end of this year, Dorine will wrap up her military career, one that began in 1984 as an U.S. Air Force officer. “When Dorine retirees, the arsenal will lose the last remaining financial analyst who built the accounting system that is in use today,” Urban said. “Although there is no one who is truly irreplaceable, Dorine comes pretty close.” For her many years of service to the Department of Defense and to the nation, Dorine LeBlanc is very deserving to be called an arsenal Face of Strength.

- 10. Page 10 Salvo Feb. 28, 2014 Arsenal Women’s History: World War II By Mark Koziol In honor of March being Women’s History month, we pause to remember the thousands of women who were employed at Watervliet Arsenal during World War II. While numerous women worked on the production lines in the manufacturing buildings, many of them were also employed in the “Siberia” section of the Arsenal performing critical duties necessary for an Allied victory over the Axis powers. These women worked hard to ensure a steady supply of needed and critical parts were sent from Watervliet to the different theaters of war throughout the world. According to a Troy Record newspaper Above photo was article May 12, 1944, taken in 1943 of archived at the ArseMiss Demetra Mouynal Museum, a lot of os. More than 3,000 women worked at women worked in the the Arsenal during unheated Siberia wareWorld War II. house building. It was here where Note: This story is a reprint from 2013, the Arsenal’s Field but is still of interest Service Depot was loas we approach cated. The Depot conWomen’s History Photos provided by the Arsenal Museum Month in March. sisted of three branchWorld War II photo of the “Siberia” warehouse that gained its name from not having any es: Stock Control; heat during the cold winters. Arsenal women processed and expedited hundreds of thouStorage branch; and sands of shipments through Siberia during World War II. Maintenance branch. At the Field Service Depot: 48 percent of the total workers were women; 85 percent of the Stock Control branch were women; and 50 percent of the employees in the Depot Storage Control branch were women. The Stock Control Section ensured proper documentation was created for both incoming and outgoing shipments of parts and they were responsible for maintaining adequate stock levels. The Stock Control branch worked closely with the Depot Transportation branch. Transportation ensured all documentation was accurate and attached to outgoing orders; and ensured a steady stream of railroad and truck transports were ready for the outgoing shipments to meet their deadlines. Hundreds of thousands of parts were processed and shipped out each month during World War II. When an order came in, women would pull specific parts from the storage bins and placed them on a conveyor that moved the parts to a series of long tables. Next, women would cover the parts with a rust preventative, wrap them in waterproof coverings and dip the package in a wax to seal it. The order would then be measured for shipment in either a ready-made wooden container or if needed, the Arsenal carpenters would custom make a crate. Many of the containers had waterproof linings constructed according to government specifications. The crates were then properly marked using a shipping number code, careful not to mention in English what was inside the crate, and shipped out. The products would arrive on time to their far-flung world-wide destination unharmed from weather or exposure to the elements. More than 3,000 women performed a variety of important tasks at the Arsenal during World War II. Without the dedicated and professional women in the “Siberia” section, who supplied the vitally needed parts to the front lines, an Allied victory over the Axis powers might have been in doubt.

- 11. Salvo Page 11 Feb. 28, 2014 Lean Corner By Karen Heiser What is a “Burning Platform” and how do we put it out? If you were standing on a “burning platform” you’d have to do something, right? You’d have a rea- son to take action. Well, a burning platform in the business world is a euphemism for identifying a company’s “reasons for action”. Reasons for action drive strategic planning and continuous improvement. How do we know what our reasons for action are? We use performance metrics to tell us when we’re doing well and when there might be a fire starting on our platform. Simple performance metrics like the number of Direct Labor Hours of work we have and our predicted revenue show us that in FY 14 Watervliet’s burning platform is workload. We have less than we need to keep our critical skills sharp, and less money than we need to cover our costs. Our FY 14 Strategic Plan, as in FY 13, continues to address the arsenal’s biggest fires on our burning platform. We have to get work , we have to be able to do it on time, to the right quality, and on budget. Action plans to achieve these goals are concentrated in four areas, or “Lines of Operation” (“LOOs”). Think of them as skill sets. The four arsenal LOOs are Products, People, Processes, and Culture. Each action plan has performance metrics to show if we’re improving. Does this have anything to do with Lean Six Sigma? Watervliet’s Continuous Process Improvement (CPI) efforts are managed through Lean Six Sigma events, which connects these events to the Strategic Plan through the Transformation Plan of Care (TPOC) process. This approach looks at the same burning platform and identifies the processes or “Value Streams” that are good targets to be improved with “Lean Six Sigma.” For FY 14, targeted Value Streams include Material Availability and Planning, and Provisioning for Execution. These Value Streams are critical in providing resources the shop floor needs to do its work. Other targets for improvement through Lean Six Sigma are Overhead Costs, the Cost of Quality, and Productive Yield. Performance metrics for these improvements will jive with the performance metrics in the Strategic Plan. Does this have anything to do with you? The Strategic Plan and TPOC define the actions we all need to take to drive the business – and the Watervliet Arsenal is a business – to a successful future. We all have a role to play in improving productivity and reducing costs. And we all have a stake in Watervliet’s successful future. The TPOC, action plan status, and performance metrics are posted in Bldg 10 outside the Commander’s office. Everyone is welcomed and encouraged to check it out. Photo by the wordvixen.com

- 12. Page 12 Salvo Feb. 28, 2014 Albany Devils Military Appreciation Game Saturday, April 12th, at 5 p.m. Save The Date Photo by John B. Snyder Former Arsenal Commander Col. Mark F. Migaleddi dropping the puck at last year’s game. City of Watervliet Memorial Day Parade Monday, May 26th Save The Date: The Arsenal is participating in the City of Watervliet Memorial Day Parade on May 26, at 10 a.m. We will need volunteers to march with the commander in the parade. We also may be invited back to the Village of Green Island’s Memorial Day Parade that will take place this year on Thursday, May 22nd.