ELW1 Poster 2013 Final Draft

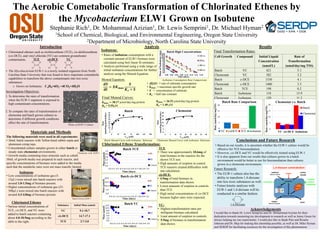

- 1. Acknowledgements Results Conclusions and Future Research Analysis Monod Equation: • dS/d t = rate of substrate consumption • 𝒌 𝒎𝒂𝒙 = maximum specific growth rate • 𝑺 = concentration of substrate • KS = half rate constant • Chlorinated ethenes such as trichloroethene (TCE), cis-dichloroethene (cis-DCE), and vinyl chloride (VC) are common groundwater contaminants. • The Mycobacterium ELW-1 is a newly isolated organism from North Carolina State University that was found to have important cometabolic capabilities to transform the above contaminants into less toxic substances. o Grows on Isobutene: Introduction C4H8+6O2→4CO2+4H2O Materials and Methods The following materials were used in all experiments: • 26mL batch reactors with Teflon-lined rubber septa and aluminum crimp tops. • Concentrated culture samples grown in either batch or steady state chemostat environments. • Growth media containing trace minerals such as cobalt. 10mL of growth media was prepared in each reactor, and specific concentrations of biomass were added to the media such that the metabolic rates were not mass transfer limited. Isobutene Chlorinated Ethenes Final Monod Curves: Final Transformation Rates:Isobutene: Chlorinated Ethene Transformation: 0 5 10 15 20 25 30 35 40 45 0 25 50 75 100 125 150 Rate (μmol/mgprotein/day) CL0 (μM) Batch 𝒌 𝒎𝒂𝒙 = 38.17 µmol/day/mg protein KS = 5.55µM TCE cis-DCE VC • Low concentrations of isobutene gas (5- 15µL) were mixed into batch reactors with around 1.0-1.5mg of biomass present. • Higher concentrations of isobutene gas (25- 500µL) were mixed into batch reactors with around 4.3-4.8mg of biomass present. • Various initial concentrations of TCE, cis-DCE, and VC were added to batch reactors containing about 4.0-10.9mg according to the table to the right. Substance Initial Mass (umol) VC 9.1-10.7 cis-DCE 14.7-17.1 TCE 2.7-3.0 𝒅𝑺 𝒅𝒕 = 𝑿𝑲 𝒎𝒂𝒙 𝑺 𝑲 𝒔 + 𝑺 0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0 13.0 0.00 0.03 0.05 0.08 0.10 0.13 0.15 0.18 Time (days) Batch High Concentrations 100 uL 200uL 300 uL 400 uL • Rates of isobutene consumption with a constant amount of ELW1 biomass were calculated using best linear fit estimates. • Analysis performed using a wide range of initial isobutene concentrations for further analysis using the Monod Equation. Cell Growth Compound Initial Liquid Concentration (umol/L) Rate of Transformation (umol/day/mg TSS) Batch VC 421 5.1 Chemostat VC 382 3.2 Batch c-DCE 1330 4.1 Chemostat c-DCE 1400 3.5 Batch TCE 198 0.2 Batch Isobutene 118 15.9 Chemostat Isobutene 129 11.2 • Based on our results, it is uncertain whether the ELW-1 culture would be effective for TCE bioremediation. • However, cis-DCE and VC would be effectively treated using ELW-1. • It is also apparent from our results that cultures grown in a batch environment would be better to use for bioremediation than cultures grown in a chemostat environment. 0 5 10 15 20 VC cisDCE TCE Isobutene Rate(umol/day/mgTSS) Future Research: • The ELW-1 culture also has the ability to transform 1,4-dioxane into less toxic substances as well. • Future kinetic analyses with ELW-1 and 1,4-dioxane will be conducted in a similar fashion. 0.0 0.2 0.4 0.6 0.8 1.0 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 Mass(µmol) Time (days) Batch TCE B1 B2 Control Investigation Objectives: 1.To determine the rates of transformation when the ELW-1 organism is exposed to high contaminant concentrations. 2.To compare the rates of transformation of chemostat and batch grown cultures to determine if different growth conditions affect the rate of transformation. Batch Rate Comparison 0 5 10 15 20 Batch Chemostat Chemostat v.s. Batch Rate(umol/day/mgTSS) Isobutenecis-DCEVC 1,4-Dioxane Photo of ELW-1 Culture Chemostat with ELW-1 0 5 10 15 20 25 30 0 5 10 15 20 25 30 35 40 Rate (μmol/mgprotein/day) CL0 (μM) Chemostat 𝒌 𝒎𝒂𝒙 = 26.52 µmol/day/mg protein KS = 1.40 µM 0.0 2.0 4.0 6.0 8.0 10.0 12.0 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 Mass(µmol) Time (days) Batch VC B1 B2 Control 1 0.0 5.0 10.0 15.0 20.0 0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 Mass(µmol) Time (days) Batch cis-DCE B1 B2 Control TCE: • There was approximately 10.6mg of total biomass in the reactors for the shown TCE test. • High amounts of sorption in control TCE reactors created difficulties with rate calculation. cis-DCE: • 4.9mg of total biomass in transformation data shown. • Lower amounts of sorption in controls than TCE. • High initial concentrations of cis-DCE because higher rates were expected. VC: • Highest transformation rates per milligram biomass calculated. • Least amount of sorption in controls. • 5.9mg of biomass in transformation data shown. Batch Monod Curve with Isobutene Substrate Chemostat Monod Curve with Isobutene Substrate Isobutene Consumption Rate Comparisons Batch Grown ELW-1 MassofIsobutene(mg) I would like to thank Dr. Lewis Semprini and Dr. Mohammad Azizian for their dedication towards mentoring my development in research as well as Jenny Green for always helping me run experiments. I would also like to thank Pete and Rosalie Johnson and Dr. Skip for making this internship possible, as well as Dr. Mike Hyman and SERDP for facilitating resources for the investigation of this phenomenon. The Aerobic Cometabolic Transformation of Chlorinated Ethenes by the Mycobacterium ELW1 Grown on Isobutene Stephanie Rich1, Dr. Mohammad Azizian1, Dr. Lewis Semprini1, Dr. Michael Hyman2 1School of Chemical, Biological, and Environmental Engineering, Oregon State University 2Department of Microbiology, North Carolina State University