Ug carbon carbon composite

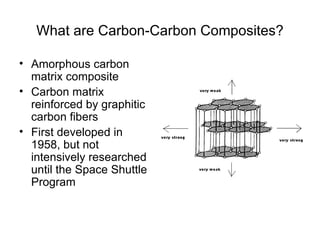

- 1. What are Carbon-Carbon Composites? • Amorphous carbon matrix composite • Carbon matrix reinforced by graphitic carbon fibers • First developed in 1958, but not intensively researched until the Space Shuttle Program

- 2. What are C/C Composites? C/C composites are lightweight, high- high- strength composite materials capable of withstanding temperatures over 3000°C. 3000° C/C composites use the strength and modulus of carbon fibers to reinforce a carbon matrix to resist the rigors of extreme environments.

- 3. Carbon-Carbon Composites • Carbon-Carbon Composites are the woven mesh of Carbon-fibers. • Carbon-Carbon Composites are used for their high strength and modulus of rigidity. • Carbon-Carbon Composites' structure can be tailored to meet requirements. • Carbon-Carbon Composites are light weight material which can withstand temperatures up to 3000°C

- 4. Properties of C/C Composites • Excellent Thermal Shock Resistance(Over 2000oC) • Low Coefficient of Thermal Expansion • High Modulus of Elasticity ( 200 GPa ) • High Thermal Conductivity ( 100 W/m*K ) • Low Density ( 1830 Kg/m^3 ) • High Strength • Low Coefficient of Friction ( in Fiber direction ) • Thermal Resistance in non-oxidizing atmosphere • High Abrasion Resistance • High Electrical Conductivity • Non-Brittle Failure

- 5. Production of C/C •Three dimensional woven carbon fiber structure •Pressure impregnation with liquid •Heat treated at 2550°C •Impregnation, DENSIFICATION and graphitization cycle repeated

- 6. Representative Weave Constructions

- 7. Fabrication of C/C Composites • Liquid Phase Infiltration • Chemical Vapor Deposition

- 8. PAN-based carbon fibers (the most popular type of carbon fibers). • In this method carbon fibers are produced by conversion of polyacrylonitrile (PAN) precursor through the following stages: Stretching filaments from polyacrylonitrile precursor and their thermal oxidation at 200°C. • The filaments are held in tension.Carbonization in Nitrogen atmosphere at a temperature about 1200°C for several hours. • During this stage non-carbonelements (O,N,H) volatilize resulting in enrichment of the fibers with carbon.Graphitization at about 2500°C.

- 9. Carbon-Carbon Composites • porous carbon-carbon composites (carbon bonded carbon fiber (CBCF)) Porosity content 70~90% ⇒high temperature insulation

- 10. Liquid Phase Infiltration • Preparation of C/C fiber pre-form of desired shape and structure • Liquid pre-cursor : Petroleum pitch/ Phenolic resin/ Coal tar • Pyrolysis (Chemical deposition by heat in absence of O2 • It is processed at 540–1000°C under high pressure • Pyrolysis cycle is repeated 3 to 10 times for desired density • Heat Treatment converts amorphous C into crystalline C • Temperature range of treatment :1500-3000°C • Heat treatment increases Modulus of Elasticity and Strength

- 12. • Processing of CBCF Discontinuous fibers (mm in length) Ground recycled CBCF (rework) mixer slurry moulding binder (phenolic resin) water 50% carbon yield porous & from phenolic anisotropic vacuum Carbonization High temp heat low pressure Product drying (950℃) treatment 99.9%℃ water (fiber alignment) gaseous impurities

- 15. Chemical Vapor Deposition • Preparation of C/C fiber pre-form of desired shape and structure • Densification of the composite by CVD technique • Infiltration from pressurized hydrocarbon gases (Methane /Propane)at 990-1210°C • Gas is pyrolyzed from deposition on fibre surface • Process duration depends on thickness of pre-form • Heat treatment increases Modulus of Elasticity and Strength • This process gives higher strength and modulus of elasticity

- 16. • Dense carbon-carbon composites Discontinuous fibers Impregnation with pyrolysis Carbonization Continuous fibers thermosetting resins 2500℃ (phenolic, furan polyimide) pitch (polynuclear aromatic hydrocarbons) Chemical vapour Dense deposition Thick enough? product

- 17. Limitation of CVD • Hydrocarbon Gases Infiltrating into interfilament surfaces and cracks , sometimes these gases deposite on outer cracks and leave lot of pores • Reinfiltration and densification required • Month long process(for specific applications)

- 22. – Stress-strain curve process dependent: Fig 4.30 Form of fiber reinforcement: Fig 4.31

- 25. Uses of Carbon-Carbon Composites http://www.fibermateri • Aircraft, F-1 racing alsinc.com/frSW.htm cars and train brakes • Space shuttle nose tip and leading edges • Rocket nozzles and tips http://www.futureshuttle.com/conference/Th ermalProtectionSystem/Curry_73099.pdf http://www.fibermaterialsinc.com/frSW.htm

- 28. Application • High Performance Braking System • Refractory Material • Hot-Pressed Dies(brake pads) • Turbo-Jet Engine Components • Heating Elements • Missile Nose-Tips • Rocket Motor Throats • Leading Edges(Space Shuttle, Agni missile) • Heat Shields • X-Ray Targets

- 29. Applications • NASA thermal protection systems • Nozzle throat inserts • Nosetips & leading edges • Space motor nozzles

- 30. Products • Variety of high temperature applications.

- 31. Heat Shields • Baffle Heat Shield • Flexi Heat Shield

- 32. Disadvantage : • Low oxidation resistance • Reacts with Oxygen at temperature above 490°C

- 33. Protection Method: • Ceramic coatings(Carbides/ Nitrides/oxides of Si,Zr,Ta,Al etc.) • Physical vapor deposition • Plasma spraying • Injecting with inorganic salts , borate & silicate glass. • Replacement of C/C matrix material by Si-C.(inhibitors of B, Si, Zr compounds)