EDM wirecut report

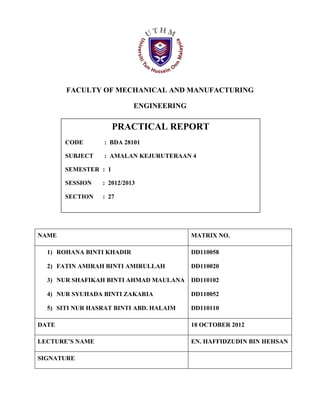

- 1. FACULTY OF MECHANICAL AND MANUFACTURING ENGINEERING PRACTICAL REPORT CODE : BDA 28101 SUBJECT : AMALAN KEJURUTERAAN 4 SEMESTER : 1 SESSION : 2012/2013 SECTION : 27 NAME MATRIX NO. 1) ROHANA BINTI KHADIR DD110058 2) FATIN AMIRAH BINTI AMIRULLAH DD110020 3) NUR SHAFIKAH BINTI AHMAD MAULANA DD110102 4) NUR SYUHADA BINTI ZAKARIA DD110052 5) SITI NUR HASRAT BINTI ABD. HALAIM DD110110 DATE 18 OCTOBER 2012 LECTURE’S NAME EN. HAFFIDZUDIN BIN HEHSAN SIGNATURE

- 2. 1.0 INTRODUCTION OF EDM WIRE CUT In wire electrical discharge machining (WEDM), also known as wire-cut EDM and wire cutting, a thin single-strand metal wire, usually brass, is fed through the work piece, submerged in a tank of dielectric fluid, typically deionized water. Wire-cut EDM is typically used to cut plates as thick as 300mm and to make punches, tools, and dies from hard metals that are difficult to machine with other methods. The wire, which is constantly fed from a spool, is held between upper and lower diamond guides. The guides, usually CNC-controlled, move in the x–y plane. On most machines, the upper guide can also move independently in the z–u–v axis, giving rise to the ability to cut tapered and transitioning shapes (circle on the bottom square at the top for example). The upper guide can control axis movements in x–y–u–v–i–j–k–l–. This allows the wire-cut EDM to be programmed to cut very intricate and delicate shapes. The upper and lower diamond guides are usually accurate to 0.004 mm, and can have a cutting path or kerf as small as 0.021 mm using Ø 0.02 mm wire, though the average cutting kerf that achieves the best economic cost and machining time is 0.335 mm using Ø 0.25 brass wire. The reason that the cutting width is greater than the width of the wire is because sparking occurs from the sides of the wire to the work piece, causing erosion. This "overcut" is necessary, for many applications it is adequately predictable and therefore can be compensated for (for instance in micro-EDM this is not often the case). Spools of wire are long—an 8 kg spool of 0.25 mm wire is just over 19 kilometers in length. Wire diameter can be as small as 20 micrometer and the geometry precision is not far from +/- 1 micrometer. The wire-cut process uses water as its dielectric fluid, controlling its resistivity and other electrical properties with filters and de-ionizer units. The water flushes the cut debris away from the cutting zone. Flushing is an important factor in determining the maximum feed rate for a given material thickness.

- 3. Along with tighter tolerances, multi axis EDM wire-cutting machining center have added features such as multi heads for cutting two parts at the same time, controls for preventing wire breakage, automatic self-threading features in case of wire breakage, and programmable machining strategies to optimize the operation. Wire-cutting EDM is commonly used when low residual stresses are desired, because it does not require high cutting forces for removal of material. If the energy/power per pulse is relatively low (as in finishing operations), little change in the mechanical properties of a material is expected due to these low residual stresses, although material that hasn't been stress-relieved can distort in the machining process. 2.0 OBJECTIVES 1. Starting a CNC EDM wire cut machines. 2. Write a CNC program. 3. Prepare and display graphics using applications Autocad and Mycam cuts. 4. Coordinate offset coordinate position of the wire cutting and die on the workpiece. 5. Programming and cutting operations on the machine. 6. Stop the machine CNC wire cut EDM. 3.0 SCOPE 1. EDM Mitsubishi Wire Cut machine is used for this project. 2. Create a part program using master CAM. 3. The wire electrode is brass wire with diameter 0.2mm. 4. The material that used is mild steel with the thickness is 5mm.

- 4. 4.0 SAFETY PRECAUTIONS WHEN HANDLING EDM MACHINES 1. Make sure there are no leaks in the tank dielectric liquid tank hose and pipe connections. 2. Make sure the materials are installed in areas where the right job. 3. Make sure the cutting wire is not touching things work. 4. Make sure each cable there is no leakage. 5. Clear oily liquid that is in place the working substance during the installation process. 6. Clean all dirt in the tank desk and storage tanks. 7. Wear appropriate clothing while using machines. 5.0 METHOD AND STANDARD OPERATION PROCEDURE (S.O.P) 5.1 Save Program (MasterCAM Program). 1) Open the drawing in the MasterCAM program. 2) Click M/C Type → wire → Mitsubishi 3) Click Toolpaths → contour → choose the directed of the machining on the drawing. Make sure the line become yellow (the drawing is continued) 4) Enter the diameter of wire 0.2mm → wire power → offset = 123 (refer the manual book) → condition code : 1021 → feed rate = 9.0 5) Compensation, click right → Flushing = ON 6) Click Properties → Stock Setup → Select corner → Verify selected option. 7) Regener → G1 → click right(to look and edit NC program). 8) The NC program will appear on the H123 change to H1=123 and delete M21 9) Save the program into the disk. 10) Slot the disk. PROGRAM → Check L No. for program. 11) I/O (M6) → Move the cursor ke L No. and fill the number of program → I/O START (M1) → wait until I/O is green. 12) PROGRAM → find the number of program → OPEN FILE (M2). (Note:Use ←↑→↓,ENTER).

- 5. 5.2 Updates program (Make sure the program is right) 1) E.S.P.E.R (make sure the screen shows PROGRAM CCHECK DATA). 2) PROGRAM SEARCH (M2). 3) Enter the number of program 62 → Y → NEXT(M8) → CONTOUR RE-DRAW (M4) → ERASE (M7) → CHECK (M1) → START (M1). 4) Automatically, the machine will check the program. If “ERROR”, check again by using; CONTOUR RE-DRAW (M4) → SINGLE BLOCK DRAWING (M5) → press M5 several times until the machine shows the line of program that “ERROR”. 5) To fixed the program, PROGRAM → Find number of program 62 → OPEN FILE (M2) → fix the program line “ERROR” → FILE (M1) → SAVE (M3) → repeat steps 1 until 4. 6) (Note: use ←↑→↓, ENTER, observe the simulation of theprogram). 5.3 Machining. 1) Make sure the work piece parallel with work table and screw tightly. The work piece also must be enough for the size of product . E.S.P.E.R. (make sure the screen shows (MACHINING DATA) – to make sure the machining flow smoothly. 2) Make sure all the information needed and right was enter. (wire’s size, wire’s type, type of work piece and others). 3) PROGRAM SEARCH (M2). 4) Enter the number of program 62 → Y → NEXT(M8) → NEXT(M8) → CONTOUR RE-DRAW(M4) → ERASE(M7) → CHECK(M1) → START(M1). 5) Observes the machining simulation. If the simulation not fill the requirements, BACK (M7) → adjust AXIS ROTATION / SCALE / MIRROR X / MIRROR Y. 6) NEXT(M8 )→ CONTOUR RE-DRAW(M4) → ERASE(M7) → CHECK(M1) → START(M1). 7) Observes the machining simulation. If the simulation not fill the requirements, WORKPIECE SETUP.

- 6. 8) To get Datum Point (0,0) machining process, turn the EMERGENCY STOP (RED) → READY → adjust AT (Automatic Threader) head by manual using teach pendant – X & Y (+ve/-ve) axis & Feed rate, make sure the distance between wire and the work piece, 1-2 mm, Observes PROGRAM POSITION (Coordinate) → adjust AT (Automatic Theader) head by manual using machine pedal (paksi Z(- ve)) - UNLOCK→ROTATE MACHINE PEDAL CLOCKWISE (CW) direction & make sure the distance between upper nozzle & work piece, 1-2 mm. 9) WKCP PICKUP (M2)→EDGE(M6) → make sure EDGE DIRECTION NO. → START (GREEN BUTTON) → Automatically the machine will find the optimum edge → RESET (blue button) →all the data in PROGRAM POSITION = 0. 10) Repeat steps 2 until 5. Observes the machining simulation by using SCALE AND VIEW POINT (M3) → TABLE SCALE POINT (M4), - to make sure the coordinate of the part that want be cut. If full the requirements, SCALE AND VIEW POINT (M3) → AUTO SCALE POINT (M3) → MONITOR → Change FEEDRATE ADJUSTMENT at minimum (to get satisfactory cutting) → START (GREEN BUTTON). 11) Wait until the machining is done. (Note: use←↑→↓, ENTER). 6.0 ANALYSIS 3mm 5 mm Drawing of the product Real product

- 7. In the process of using Electrical-Discharge Machining (EDM) Wire Cut machine, we are using Brass wire of 0.2mm diameter to cut Aluminium plate which has thickness of 5mm. At the end of the process, we got the end product with the desire shape which is the shape above. The process to cut the workpiece took about 10 minutes.After we get the real product, we do some analysis regarding its dimensional. We have measure the output and get the same measure as the drawing. Therefore, we know that EDM wire cut machine could produce accurate product base on the drawing. As our product is very small with 5mm x 5mm and the machine could cut it, so the machine is capability in cutting small and complex part. Wire EDM cutting, also known as electrical discharge machining, is a process that uses an electrically energized thin wire to slice through metal. Wire EDM cutting uses rapid, controlled, repetitive spark discharges from the wire to the work piece, thereby eroding the metal away. The work piece must be electrically conductive. Wire EDM can cut material thickness from only a few thousandths of an inch to several inches. Custom tooling is generally not needed.

- 8. Wire EDM cutting can provide high dimensional accuracy for close fitting parts. The process can make sharp inside corners. The machine also can cut most any simple or complex 2D shape including cutouts and thin walls, intricate openings and sharp inside corners. Examples of a few types of parts that can be cut by wire EDM include: Custom gears Custom robot parts Wire EDM cutting applies to 1. Steel Steel is a metal alloy consisting mostly of iron, typically with small amounts of carbon although other elements may be included such as manganese, chromium, vanadium and tungsten. Modern steel making began in 1858 with the capability to produce large quantities cheaply. Mild steel is used for numerous applications where wrought iron was used previously. Steel shapes include sheet, rod, plate, hex, pipe and a variety of beams. Sheets are generally under 1/4 inch. Steel plate is generally above 1/4". Cost optimization options for wire EDM cutting include: Reducing cut surface area Stacking parts during cutting (this is considered automatically by the eMachineShop CAD) Minimizing the number of holes and cutouts Creating holes by providing a small gap connecting the hole to the outer edge. Wire EDM Design Considerations Edges are smooth but matte. Typical surface finish is between 16 and 64 microinches. The edges of the finished work piece will have virtually no burrs. Kerf width typically ranges from 0.001" to 0.012". Sharp internal corners will be slightly rounded (typically with radius ~.008").

- 9. 6.1 Advantages and Disadvantages of Edm-Wire Cut EDM-Wire Cut also has its own particular advantages. The machine capability is cutting materials regardless of its hardness. EDM-Wire Cut is much faster than EDM. It can cuts intricate shapes, narrow slots, small products and others. Furthermore no burrs generated during the process. The wire electrodes used are much cheaper than shaped electrodes in EDM. Nowadays, EDM-Wire Cut cables to cut tapered shape products.Electrical Discharge Machining or EDM is a highly accurate method of part production. Wire EDM technology is essential for higher tolerance parts and repeatable tooling. Tolerances are held to ±.0002" in our temperature controlled facility. Achieving high accuracy and tighter tolerances is essential for many industries such as aerospace, medical, injection molding and tool and die. Besides that, EDM-Wire Cut also has disadvantages. The EDM-Wire Cut Machine more expansive than other machine. High skills are required to handle the machine. The work piece only conductors can be machine. EDM-wire cut have slow material removal rate (MRR) and less flexible compared others machine. 7.0 CONCLUSION AND RECOMMENDATION The desired objectives have been successfully implemented. Any guidance given by lecturers is very useful and effective. We have been successfully EDM wire cut machine with skill and know how to enter the program and run machine for the design of the products made. In addition, we also know how to apply the program to form the G-code to get the result as above. All that was taught to us was really helpful to our advantage as we go into the working world later.

- 10. It can be concluded that:- a) Wire EDM, or electrical-discharge wire cutting process is based on the principal energy mode is thermal with the electrical discharge. It is also similar to contour cutting with a band saw, a slowly moving wire travels along a prescribed path, cutting the workpiece, with the discharge sparks acting like cutting teeth. b) This process is used to cut plates as thick as 300 mm (12 in.), and for making punches, tools, and dies from hard metals. It can also cut intricate components for the electronics industry. c) Special brass wires are typically used and usually performed in a bath of water. d) As technology advances in speed, workpiece size and geometry complexity, accuracy, ease of use, unattended operation, industry education and affordability. In the case of complicated shapes requiring cuts or angled, conical, or other unusual surfaces, the upper and lower wire guide systems carry out differing movements accordingly. One of the most important recommendations to buy EDM-Wire Cut is that due to the ability to cut any material regardless of its hardness but only conductor materials. Besides that, the absence of all-mechanical forces makes it possible to machine fragile parts without distortion. It is so recommended due to its high accuracy thus producing a high quality product. Less labour is required to operate but must be well trained. This will reduce overall production cost and increase profit of the company

- 11. 8.0 ENCLOSURES