Medical Plastics News November-December 2012

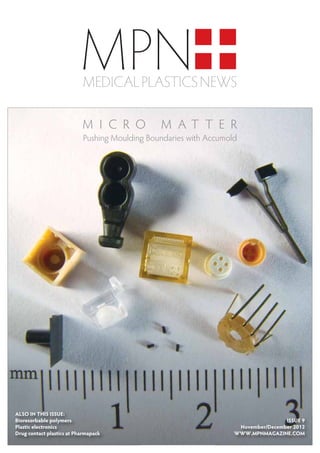

- 1. MPN MEDICAL PLASTICS NEWS M I C R O M AT T E R Pushing Moulding Boundaries with Accumold ALSO IN THIS ISSUE: Bioresorbable polymers ISSUE 9 Plastic electronics November/December 2012 Drug contact plastics at Pharmapack WWW.MPNMAGAZINE.COM

- 3. MPN All Medical, All Plastics Contents 5. Editor’s Letter: A thousand miles 26. Folio: Liquid silicone As the MPN journey moves into its thrid A low-viscosity, addition-curing silicone year, I take a look back at the steps that for soft compression effects. brought us to where we are today, including the most recent Compamed 29. Country Report: Germany Editor’s Letter—page 5 and Medica shows in November 2012. Germany is the European leader in innovation—second only to the USA in 6. On the Pulse: Proposed regulation terms of patent registrations. The report The key changes in the 194-page is followed by a round up of medical European medical device regulation plastics research institutions in Germany. proposal are outlined. Also, news of the devices and diagnostics ally MedTech 34. Cover Story: Micro matter Europe. Pushing micro moulding boundaries with Accumold. 11. The SPE: Supercritical CO2 Plastic Electronics—page 14-16 Supercritical gases are being used as 37. Design 4 Life: Licensed to Cure plasticisers, to improve processing of Dassault launches dedicated medical viscous high molecular weight polymers, device design sofware. Bioresorbable Polymers—page 18-25 and for injection moulding of foams. 38. Modular Cleanrooms: A guide 14. Plastic Electronics: Smart switch Sean Fryers of Connect2Cleanrooms A report from Engel about moulding gives us a glimpse into the versatile wipe-clean capacitive electronic switches world of modular cleanroms. by overmoulding film-based printed electronics. Also, news that resorbable 41. Doctor’s Note: Plastic and 3D Tomo electronics are a reality. Machined plastics help physicists test performance of 3D digital breast 18. Materials: Bioresorbable polymers tomosynthesis imaging equipment. Folio—page 26 US patent applications referencing resorbables have grown by 37% a year 42. Pharmapack: Drug contact plastic in 2005-11. Sam Anson investigates why. Interview with Steve Duckworth, head of The article covers compounding, medical and pharma at Clariant, about mechanical properties and degradation additives for cyclic olefins, extractables times, moulding and extrusion, additive and leachables by Joy Harrison of manufacturing of resorbable tissue Smithers Rapra, and “out of the box” engineering scaffolds, Absorb—the first packaging design from Team Consulting. resorbable stent, Purac glass fibre composites, supercritical CO2 50. Events: Diary and VinylTec sterilisation, and coloration. Medical plastics diary in Q1 2013 and a review of SPE’s VinylTec conference in Chicago by Jodie Laughlin. Online and in digital Medical Plastics News is available online, at www.mpnmagazine.com, and Pharmapack Preview—page 42-49 in digital (on the iPad, mobile phones and computers). NOVEMBER/DECEMBER 2012 / MPN /3

- 5. MPN | EDITOR’S LETTER MPN | CREDITS editor | sam anson advertising | gareth pickering art | sam hamlyn A journey of a thousand miles Illustrating our achievements so far, begins with a single step. This phrase by Jesper Laursen of Danish compounder production | adrian price Chinese philosopher Lao Tzu, who died Melitek, said to me this month: “I saw in 531 BC and was a contemporary of your article about DEHP and wanted to Confucius, sums up very nicely where commend you on the result. You pulled subscriptions | tracey nicholls things have come in the last 18 months together information from a lot of at Medical Plastics News. interest groups which had the potential publisher | duncan wood The first step on the Medical Plastics to get very complicated. You reported News magazine journey was taken two the issues accurately, independently years ago—in November 2010—when and carefully and this demonstrated I flew to Düsseldorf to visit the Medica your professional skills. You have shown and Compamed shows for the first that you are a proper journalist and time. The trip was booked after I had MPN is a proper magazine.” Medical Plastics News is available on free presented to my publisher the original Chris James of Monaco-based subscription to readers qualifying under idea for a magazine dedicated to medical plastics company Promepla also the publisher’s terms of control. Those medical applications for plastics. congratulated me. He said: “MPN fills a outside the criteria may subscribe at the I headed there with the goal of gap in the industry for plastic following annual rates: UK: £80 making as many contacts as possible at manufacturers. It is highly relevant, the Europe and rest of the world: £115 companies involved in the use of content is well researched and plastics for medical applications. I was insightfully written. Sam—your pleased to find that the show was a knowledge of medical is impressive.” Medical Plastics News is published by: hotbed of advanced medical plastic Lao Tzu’s philosophy is helpful Plastics Multimedia Communications Ltd, technologies. because it encourages people to achieve Unit 2, Chowley Court, By the time I arrived at Compamed things that they would otherwise deem Chowley Oak Lane, the following year, our thousand-mile impossible. By breaking things down into Tattenhall, CH3 9GA journey had well and truly begun. In the small parts, a task of a size or complexity T: +44(0)1829 770037 preceeding twelve months, together too great to tangibly conceive instantly F: +44(0)1829 770047 with my colleague Gareth Pickering, I becomes achievable. And this is a useful had developed and published three outlook on other aspects of work, as well issues of a new medical device maga- as life in general. zine concept covering the medical © 2012 Plastics Multimedia << At Compamed 2012, Friedrich Communications Ltd plastics supply chain. The model enc- Echterdiek from moulder Spang & ompasses resin supply and pricing, While every attempt has been Brands shone a light on cost saving for made to ensure that the information design and materials selection, machin- bag manufacturers, like investing in ery and auxiliaries, processing methods contained within this publication is tooling for a twin shot cap design, accurate the publisher accepts no including moulding and extrusion, end reducing assembly steps and of line technology, regulation as well as liability for information published in simplifying manufacturing. Image error, or for views expressed. All product focuses and clinician reviews. courtesy of PR Portfolio. >> A year on and I have just returned rights for Medical Plastics News are from my third Compamed and Med- reserved. Reproduction in whole or ica event in a row. Being familiar with in part without prior written the layout of the halls at Messe Düss- permission from the publisher is eldorf certainly helps make the most strictly prohibited. of the short time available at the event. But representing what is now a recognisable brand in MPN is a big BPA Worldwide plus when lining up interviews with Membership important industry representatives. Furthermore, our pledge of editorial ISSN No: 2047 - 4741 (Print) independence and technical accuracy 2047 - 475X (Digital) has clearly built a firm foundation of trust and reassurance in the industry. NOVEMBER/DECEMBER 2012 / MPN /5

- 6. INDUSTRY NEWS | Medical Device Regulation Europe’s Proposed Medical Device Regulation WORDS | SAM ANSON On September 26, 2012, the implementation of existing rules from one administration of the regulation and the European Commission issued a proposal member state to another as evidenced by scrutiny procedure related to high risk to overhaul regulations for medical recent reports by UK newspaper The class III implantable devices (see later). devices and active implantables. The Telegraph. It is also directed towards proposal document is 194 pages long addressing the problem related to post- Economic Operators and is a more stringent approach to market surveillance, highlighted recently by With a view to achieving better device regulation. It aims to bring about a the PIP silicone implants scandal, whereby transparency and traceability, Chapter II transparent and traceable supply chain competent authorities do not have sufficient sets out requirements for economic focusing on the life cycle of a broader mechanisms to monitor information and operators—manufacturers, authorised range of products. implement market surveillance. representatives, distributors and If implemented, being a regulation importers. The responsibilities of all Definitions rather than a directive, it will be applied “as economic operators are defined. is”, bringing consistency across EU states. There are more definitions in the Manufacturers and authorised The terms of the regulation itself areproposal document than the MDD—50 representatives must have an approved subject to change following discussion and compared with 14. The definition of a qualified person appointed who is an approval by the European Parliament. medical device has been expanded to expert in the field with qualifications. Once the final wording of the include aesthetic implantable devices (for There are also requirements placed on regulation is published it will enter into example cosmetic breast implants or non- the manufacturer with respect to force 20 days later and come into full corrective contact lenses) and invasive quantity-structure-property relationships devices used in humans with associated effect three years after that. Therefore, it (QSPRs), technical documentation, quality is likely to be at least 2017 before examples. management systems, post-market manufacturers are required to comply. surveillance plans and clinical follow ups Medical Device Coordination Group and labelling languages. Weaknesses of the MDD The proposed regulation would involve As far as distributors and importers are The new proposal aims to correct the establishment of an expert committee concerned, imported devices must bear weaknesses in the current Medical Device called the Medical Device Coordination the importer’s name on the device or its Directive (MDD). The biggest change Group, made up of members from EU packaging. There are requirements that concerns the oversight of notified bodies— states and chaired by the EC. The group importers must carry out sampling of which has led to inconsistency of will be responsible for marketed products while monitoring Former surgeon and Eucomed chairman October 9, “There has also been Dr Guy Lebeau (pictured) said: “I urge 2012 North heightened focus on all decision makers who want to make American Sales engineered polymers fundamental changes to the European such as co-polyether- October 10, system for medical devices to tread with of Medical ester elastomers 2012 caution. I fully agree that changes need Plastics to (COPE), polyether October 1, 2012 to be made to the current regulatory Grow by block amides (PEBA), Eucomed and EC Publishes framework but let’s make sure we keep 5.2 per cent a and acetal chemistries EDMA Launch Proposed medical the best system for patients and medical Year to 2018 that have more MedTech Europe, progress in Europe.” advanced performance a New Allied device Regulation properties for niche, Devices and technologically October 8, 2012 advanced healthcare Diagnostics Abbott Launches applications, such as Association tissue engineering and First Ever Fully implants,” said research Resorbable analyst Tridisha Vascular Stent Goswami. “These new “Abbott has remained committed to meeting the growing physician and patient materials will expand demand for a bioresorbable vascular scaffold—from the initial device the scope of plastic developed nearly 10 years ago to the expansion of our manufacturing polymers' application capabilities to support this international launch,” said John M Capek, executive and propel the vice president, Medical Devices, Abbott. market.” 6/ MPN / NOVEMBER/DECEMBER 2012

- 7. ON THE PULSE complaints. Furthermore, these entities Notified Bodies Eudamed database registration is must declare that they have complied with Perhaps the greatest proposed itemised. The process for a post-market the requirements of the relevant clauses in change to the regulatory system surr- clinical follow-up is also explained. the proposed regulation document. ounds notified bodies and their metamorphosis from an industry partner Market Surveillance and Serious Additional Device Types into what Emergo describes as “a police- Incidents New devices to be included and like extension of the authorities’ market Under the proposal, manufacturers are specifically defined are: devices surveillance apparatus”. required to report a serious incident within incorporating medicinal product and Existing notified bodies will be subject 15 days. The EU database will be used to devices composed of substances or a to annual monitoring by authorities and share these reports to relevant bodies. combination of substances intended to an assessment once every three years by be ingested, inhaled or administered a joint assessment team. There are also Industry Response rectally or vaginally; devices incorporating new minimum requirements for notified In general, the proposal has been materials of biological origin; and bodies, set out in annex VI. welcomed by the industry. However, there software in devices and standalone The proposal also sets out terms for have been concerns that the proposed software. the so-called scrutiny procedure—how a scrutiny procedure for high risk class III notified body should notify the Medical devices is too tough and could stifle Eudamed Medical Device Database Device Coordination Group about new technological development and delay and Unique Device Identifiers (UDIs) implantable class III devices, including the device uptake—a key competitive edge of Chapter III proposes a process by which presentation of a Summary of Safety and Europe’s medical device industry at present. devices can be tracked within the EU. It Clinical Performance document created At the same time though, other consists of a newly established medical by the manufacturer. When explaining commentators have suggested that the device database—known as Eudamed— this requirement, Emergo pointed out proposal should be taken with a degree with a mandatory requirement on notified that many manufacturers may not have of political context. The Eucamed bodies, economic operators and member completed this document at this stage. database will require an increase in spend states to input data. A key component of Overall, the proposed legislation over by the European parliament and medical the system is the unique device identifier notified bodies is expected to be costly. devices may not be outside the current (UDI), a set of data which must be compiled climate of austerity for many member and submitted for every device sold in the Clinical Evaluation and Investigation states. Getting the funding for the EU market. It is proposed that class III As was generally expected, the roles proposal through parliament may not be devices will be separated out and subject to of clinical evaluation and investigation are as easy as many people think. a separate scrutiny procedure and, as part more prominent in the proposed of the data submitted, a summary of safety regulation than in the MDD. There are Credits: The above article was compiled using and clinical performance must be included. requirements quoting specific ISO information from medical device regulation consultants Emergo Group and Meddiquest. standards and guidance documents and “The [MedTech Europe] October 24, PREVIOUSLY ON MPNMAGAZINE.COM alliance not only signifies a 2012 ABHI 12:12:2012 stronger and more consistent representation of Admits Notified Europe’s medical technology Bodies industry, but also provides October 23, 2012 Problem healthcare stakeholders with October 31, “The PVCMed Alliance will actively Polycarbonate Following one unified industry 2012 European communicate about PVC and its Producers Condemn Telegraph additives, its properties and its discussion partner when Medical PVC needed. Being able to speak French Proposed Ban Undercover essential contribution to quality Industry care delivery for healthcare with one organisation about of Bisphenol A Report medtech issues should make Forms PVCMed professionals. It will also promote The European Information David Jones, director of the lives of healthcare Alliance innovative and environmentally Centre on Bisphenol A, a Communications at ABHI, players easier and makes friendly practices in PVC healthcare sub division of European said: “The Daily industry representation applications”, explains PVCMed plastics industry Telegraph’s investigation more credible and Alliance spokesperson Brigitte Dero. association PlasticsEurope, into Notified Bodies (NBs) impactful,” said Serge comprises representatives highlights an issue that 24 Bernasconi, chief executive from the main ABHI has raised with officer of Eucomed, the polycarbonate producers authorities on a number of European Diagnostics in Europe—Bayer occasions. The control of Manufacturing Association MaterialScience, Dow, NBs across Europe has not (EDMA) and MedTech Sabic, Styron and been rigorous enough and Europe. Momentive. this must be improved.” NOVEMBER/DECEMBER 2012 / MPN /7

- 8. 8/ MPN / NOVEMBER/DECEMBER 2012

- 9. ON THE PULSE INDUSTRY NEWS | Devices and Diagnostics Industries Ally www.reforminghealthcare.eu website. The new report on Allied Medical Devices and value-based innovation focuses on how Europe's medical technology industry is delivering on a promise of a Diagnostics Industry Group “Contract for a Healthy Future”. The updated industry strategy document, entitled Industry Strategy, Contract MedTech Europe for a Healthy Future, details the role of Europe’s medical technology industry in steering healthcare systems onto a WORDS | SAM ANSON sustainable path. Together with a third report by the Economist Intelligence Unit on Future-proofing Western On October 10, 2012, the The alliance will be Europe’s Healthcare, these reports are available as a free associations representing legally established by download on the reforminghealthcare.eu website. the European manufacturing the end of 2012 and The board of Medtech Europe will comprise three will collaborate closely industries for medical representatives from EDMA and three representatives on common policy devices, Eucomed, and from Eucomed. The chairmanship will rotate between its interest areas. All diagnostic devices, the members. The board will decide future topics of European medtech collaboration. European Diagnostics associations are invited Announced as a European Industry Alliance in January Manufacturers Association to join. 2012, MedTech Europe will work alongside its founding (EDMA), announced that Initially, MedTech members and will remain a separate entity, as will EDMA they had formed MedTech Europe’s focus will be and Eucomed. Medtech Europe is not an umbrella divided into five Europe, a new alliance association on top of Eucomed and EDMA. parts—legislative intended to encourage The three associations will be helmed by one chief frameworks for medical collaboration between the executive officer—Serge Bernasconi. Mr Bernasconi devices and in vitro succeeded the previous chief executive of Eucomed, two industries. The diagnostic (IVD) Luciano Cattani, and director general of EDMA Volker announcement was made at products; the European Oeding on July 16, 2012. the European MedTech medical technology Forum in Brussels, Belgium. industry’s five-year strategy; health << Serge Bernasconi is the technology assessment; patients and safety; and chief executive officer of environmental issues. the newly formed allied Medtech Europe has made a strong start to its role as Medtech Europe as well as an ally between the medical device and diagnostics Eucomed and the European manufacturing industries. It has published a new report on Diagnostics Manufacturers value-based innovation, updated an industry strategy Association (EMDA). >> document and overhauled the Reproduced with kind The Purpose of a Diagnostic Test permission of Eucomed. by Lluís Bohígas Santasusagna, director, institutional relations, Roche Diagnostics In vitro diagnostic (IVD) tests are being created for Screening consists of studying patients who do not yet home use, empowering patients with information about present any signs or symptoms of a specific illness in order their health and giving doctors the tools to optimise to find out if it has begun to quietly develop and if so, to treatments. be able to apply treatment as soon as possible. These tests Diagnosis is the process of finding out if a patient has are applied to large segments of the population and a specific disease. A medical professional prescribes a test should therefore be simple and cheap. to make a diagnosis or to exclude possible illness. The Prognosis allows clinicians to assess the likelihood a results are used to implement treatment or carry out patient has for developing a disease in the future and further tests. therefore take precautions earlier rather than later. Genetic Monitoring intends to see if the disease is controlled, tests, for example, analyse a patient’s predisposition for a purpose that is very common in chronic diseases such as developing a disease, allowing the patient and doctor to diabetes. Symptoms can be managed with medication, be more attentive to discovering early signs of the disease hormones or lifestyle changes. and to take preventive measures as needed. NOVEMBER/DECEMBER 2012 / MPN /9

- 10. 10/ MPN / NOVEMBER/DECEMBER 2012

- 11. ON THE PULSE Industry News from the SPE | Supercritical Fluids in Medical Plastics Supercritical CO2 in BY DR SEAN LYONS, SENIOR SCIENTIST AT Medical Plastic Processing BAUSCH + LOMB, IRELAND The use of supercritical CO2 as a solvent in the CO2. Biomaterials as well as polyethylene and polystyrene processing of various biodegradable and biocompatible blends have exhibited similar behaviour. polymers for pharmaceutical and medical applications in the forms of particles and microcellular foam has Plasticisation garnered much attention in the last decade. A The use of supercritical fluids in the processing of supercritical fluid is defined as a substance for which both polymer melts can also lead to changes in the mechanical pressure and temperature are above the critical values. properties of the materials. Most mechanical property These fluids possess physicochemical properties— changes during processing can be attributed to the properties which are both physical and chemical—such as plasticisation of the polymer by the supercritical fluid and density, viscosity and diffusivity. Density, viscosity and the resultant drop in Tg. Some blended polymer materials diffusivity are intermediate between those of liquids and have shown significant increases in modulus and strength gases and are continuously adjustable from gas to liquid when formed in a supercritical fluid assisted process, this is with small pressure and temperature variations. Both the often due to the tuning of the morphology and degree of capability of supercritical fluids to replace toxic solvents crystallisation of the material by the supercritical fluid. and the ability of tuning solvent characteristics for highly Changes in the elastic and creep modulii of materials when specific separations or reactions have led to the current processed with supercritical fluids can occur in a range of scientific and industrial interest in supercritical fluids. A materials. However these changes and their magnitude are supercritical fluid has the unique ability to diffuse through dependent on the solubility of the polymer(s) in the solids like a gas, and dissolve materials like a liquid. CO2 is supercritical media and the supercritical material’s ability to a promising alternative to noxious organic solvents and induce crystallisation in the system in question. chlorofluorocarbons. It has shown versatility as a supercritical fluid in the synthesis as well as processing of Supercritical Fluids in Fibre Composites polymers owing to its attractive physical properties. It is Polymer composites processing can also utilise non-toxic, non-flammable, chemically inert and supercritical fluid technology and extensive research has inexpensive. Its supercritical conditions are easily attained taken place in this area recently due to the burgeoning use (Tc = 304.15 K, Pc = 7.38MPa) and it can be removed of these materials in the electronic and medical industries. from a system by simple depressurisation. Companies such as Ireland’s SCF Processing have been pioneering research into bespoke industrial polymer A Processing Aid for Viscous High Molecular Weight processing solutions working with manufacturers to Polymers provide tailored materials processing transfer services. The processing of polymers is highly influenced by the Supercritical fluid can be used to carry the monomer onto viscosity of the bulk materials. Raising the processing the fibres or particles to be used in the composite and to temperature or the addition of volatile or harmful act as a plasticiser for the synthesised polymer matrix when plasticisers are often seen as solutions in overcoming the the composite is formed by in situ polymerisation of the inherent difficulties encountered when processing high monomer. Polymer composites can also be prepared by molecular weight polymers. However, higher temperatures blending the polymer and the other component in the during processing can lead to thermal degradation. Also, presence of supercritical media. added plasticisers remain in the product and thus alter its properties and performance. The low thermal stability of Microcellular Foam Products high molecular weight biodegradable polymers has led to The moulding of microcellular foam products, like many the emergence of supercritical CO2 as a useful processing supercritical CO2 processes, entails the formation of a single aid. There are many examples of the use of pressurised phase solution. On venting the CO2 by depressurisation, gases to lower the melt viscosity of numerous amorphous thermodynamic instability causes supersaturation of the CO2 and semicrystalline polymers. Polyethylene glycol, dissolved in the polymer matrix and hence nucleation of polystyrene and polydimethylsiloxane are examples of cells occurs. The growth of the cells continues until a polymers where a viscosity reduction has been significant amount of CO2 escapes, the polymer passes demonstrated upon the incorporation of supercritical Continued on page 13 NOVEMBER/DECEMBER 2012 / MPN /11

- 13. Continued from page 11 ON THE PULSE through its Tg and the foamed structure 50%, reduced scrap rates, and lower Organisations Collaborate is frozen in place. An added advantage energy consumption (energy savings of this technology is that due to the are based on reduced processing on PVC in Healthcare lower pressures and softer fills, delicate temperatures and are process A new European association, items can be overmoulded without dependent); lower capital costs the PVCMed Alliance, has been much of the traditional displacement through the purchase of smaller and launched to promote the use and and resultant need for excessive control fewer machines, and fewer and less value of PVC in healthcare features. USA-based Trexel’s MuCell expensive moulds; reduced material applications. PVCMed is an process technology is said to have been costs through component density alliance of the PVC medical the first to widely offer microcellular reduction, thinner design, and material industry chain represented by foaming for both extrusion and injection substitution; and the ability to mould PVC resin and plasticiser moulding processes and as a result its thermoplastic parts that have a producers and PVC converters. technology is often licensed to substantially higher dimensional stability The alliance’s aim is to provide a industrial partners. Optifoam licensed which are free of warpage. focal point for communication with by Switzerland’s Sulzer Chemtech is an The use of supercritical fluids in the healthcare professionals and example whereby the supercritical fluid medical device sector affords the regulators about PVC-based dosing element is the nozzle of the opportunity to add a new and exciting healthcare applications, and their machine as opposed to the barrel. dimension to the processing of fundamental role in quality of Another example is Ergocell, the polymeric materials. Examples of healthcare, safety and cost- injection moulding process operated medical devices currently being efficiency, all whilst being by Japan’s Sumitomo (SHI) Demag for produced commercially using this environmentally responsible. the production of microcellular foamed technology include endoscopes, heart Through an interactive platform, products. The cycle sequences in the pumps, inhalers and nebulisers. The use Ergocell process essentially correspond of supercritical CO2 as an inexpensive the alliance seeks to consolidate a to the sequences in the standard solvent in many polymer processing strong dialogue with all involved injection moulding process. The applications has already brought many stakeholders to continue decisive difference is in the gas benefits to the industrial sector. As improving healthcare delivery delivery, which takes place usage becomes more widespread, together. simultaneously to plasticising. As the materials that had previously been “The PVCMed Alliance will screw draws in, melts and delivers designated as ‘un-processable’ due to actively communicate about PVC material into the space in front of the their high viscosity or their thermal and its additives, its properties and screw and—in the process—is being instability can now be reinvestigated its essential contribution to quality pushed back against the back pressure, with the aid of supercritical fluids. care delivery for healthcare gas is fed into the melt from a gas Supercritical fluid technology has not professionals. It will also promote metering station. Thus, the screw moves yet reached its potential within industry. innovative and environmentally back at a speed that is a function of the However, considerable research into friendly practices in PVC plasticising capacity of the screw. this field is ongoing which would healthcare applications”, explains Simultaneously, an amount of gas as indicate that the number of applications PVCMed Alliance spokesperson preset by the operator is delivered and the usage of this technology are Brigitte Dero. Ms Dero adds: “The into the melt. In contrast to the MuCell only likely to grow. Supercritical CO2 is quality and safety of PVC-based technology, which requires a modified also examined as a sterilant of healthcare applications guarantee screw assembly, the injection of the bioresorbable devices on pages 22-25. efficient and widely affordable supercritical fluid into a module Medical Plastics News would like healthcare systems to continuously downstream of a conventional to thank Austin Coffey of the Society improve and save patients’ lives.” plasticisation unit in the Ergocell of Plastics Engineers European At the time of going to press, technology means that it can be easily Medical Polymers Division for his help members of the PVCMed Alliance removed, allowing the injection with this article. include BASF, Colorite Europe, moulding equipment to be used in a Eastman, the European Council of conventional process when required. Vinyl Manufacturers (ECVM), OXEA, Renolit and Tarkett. Advantages of Supercritical Gas Assisted Injection Moulding The primary advantages of supercritical gas assisted injection moulding are: reduced operating costs through cycle time reductions of up to NOVEMBER/DECEMBER 2012 / MPN /13

- 14. Electronics in Plastic Devices | Smart Plastics At the Touch of a Button: Wipe-Clean Moulded Switches for Medical Engineering For electronic medical devices, control Some people have earmarked smart plastics as a components such as switches and buttons converging technology where capacitive electronics have been combined with injection moulding. Others have must not only be easy to operate—they described them as a new type of composite technology. must also be easy to clean. They are Fundamentally, they consist of a plastic part moulded notorious for attracting germs and dirt over a film which has had electronic components printed particles, particularly in and around the onto it (see image below left). The result is an aesthetically pleasing part with smooth lines and a clean shiny finish. tiny crevices and gaps between the The part has electronically interactive parts built in to it to various components and connections. The form switches and buttons. development of smart plastics—moulded The electronics components consist of capacitive components with capacitive electronic sensors which utilise the principle of electrical capacity— the reciprocation between two spatial points (as in the functionality—offers device electric force field between two electrodes). The electric manufacturers the opportunity to flux lines within an electric field may be changed by develop wipe-clean electronic buttons introducing a conductive object (such as a fingertip). The and switches while improving production capacitive sensors pick up these changes and respond with a voltage variation that can be used to initiate a efficiency and achieving better and more particular function—such as an on/off or up/down complex designs. command. Since the field lines penetrate non-conductive solid bodies, the sensor effect also works from a distance through a thin surface layer such as a thermoplastic or an operator's gloves. << Below: Sensors and conducting paths are printed onto the film; the malleability of the film gives product designers ample scope. >> << Above: Smart plastics represent new opportunities for the medical engineering sector, especially in the design of operator control units. >> 14/ MPN / NOVEMBER/DECEMBER 2012

- 15. PLASTIC ELECTRONICS The films can be configured in three dimensions and no assembly is required, productivity is also increased cut before being overmoulded or back-injected with sharply. thermoplastic. In this way, capacitive electronics can replace mechanical switches, buttons and control knobs. Pushing the Boundaries of Product Design The operating elements are covered by a continuous, Ample scope for design through injection moulding is even and highly resistant interface. a real benefit here. The flexible print production for the films makes it possible to position sensors almost Smart Plastics in Cars anywhere; films can also be formed into virtually any According to Austrian injection moulding machine shape. Sensitive surface technology is therefore the ideal manufacturer Engel, smart plastics have undergone most means by which to develop operator control units cost development in the automotive sector. Michael Fischer effectively—units that Engel say are unbeatable in terms (pictured right overleaf), sales manager (technologies) of usability and ergonomics. believes: “The cars of the future will be easier to operate than smartphones, simply by touch, feel and interaction.” At its open house in June 2012, Engel presented its first close-to-production application for smart plastics (see image). Centre consoles for cars with a sensitive interface were manufactured using an Engel duo 350 injection moulding machine with reversing plate and combination mould. A capacitive, three-dimensional pre-formed film was placed into the mould by a robot and overmoulded with PC/ABS. The component was then flow-coated with polyurethane to protect the surface and produce a high quality impression. << Injection moulding covers the electronic elements with a continuous and highly resistant plastic interface. >> Of course, ergonomics and cost-effectiveness have been key considerations in other sectors of industry for many years. With this in mind, a design study for the control panel of a washing machine was recently presented. Meanwhile, Engel and its partners are starting to field enquiries from the medical engineering sector. “I think the fact that this technology addresses a whole set of requirements at a stroke represents a major << The manufacturing cell for centre consoles with capacitive opportunity for medical engineering”, says Christoph electronics delivers outstanding cost effectiveness. A high Lhota (pictured middle overleaf), the head of Engel's level of automation—and the sensitive surface technology medical business unit. “Firstly we're doing more to itself—are critical factors. >> address stringent hygiene requirements, secondly we're improving the ergonomics of medical engineering The technology will now be marketed under the name products and thirdly we're drastically cutting production Sensitive Surface by Engel and its project partners. “We costs. Pressure on costs is rising in the medical are in discussion with various automobile companies and engineering sector too.” OEMs with a view to mass-producing the first sensitive At present, lessons learned from the automobile surface applications in three to four years”, reveals Fischer. industry are being developed and applied to the medical In the case of vehicle construction, the hygiene engineering field. Alongside Engel, a company heavily aspects of a continuously sealed interface are less involved in the specialist development and production of important than ease of use and high efficiency in the intelligent, multi-layered interfaces is Austria- manufacturing process. Whereas conventional headquartered smart plastics technology developer manufacturing often involves the individual production plastic electronic. One key development issue at present is and assembly of more than 100 small parts, capacitive the sterilisability of intelligent electronic components. “We films and plastic granulate facilitate the production of successfully carried out function tests for the automobile functional, ready-to-install components in a single work industry in the temperature range of -40°C to +85°C”, step. “Taking the centre consoles as an example, reports Philipp Weissel (pictured left overleaf), CEO of production costs are reduced by at least 30% if we look at the whole process”, emphasises Michael Fischer. Since Continued on page 16 NOVEMBER/DECEMBER 2012 / MPN /15

- 16. PLASTIC ELECTRONICS Electronics in Plastic Devices | Smart Plastics Continued from page 15 plastic electronic. “We're now working on raising the Bioresorbable Electronic temperature range for critical applications in medical engineering.” Devices a Reality Upper Austria Hailed as Epicentre of Smart Plastics It’s not often that a doctor can claim two game- Evolution changing inventions in less than a year. That’s what Dr As far as the future research activity of Engel and Marvin J Slepian can boast, having developed a new class plastic electronic is concerned, Upper Austria promises of small, high performance electronics that are ideal conditions. Few places elsewhere in the world are biodragradable and capable of dissolving completely in such a high concentration of companies and research water or bodily fluids following a predefined period of institutes to be found alongside the infrastructure needed functionality. Earlier this year, Dr Slepian’s company, for smart plastics. Early in 2011, this density of specialist Syncardia—a US-based medical device manufacturer— expertise led to the foundation of a smart plastics developed and successfully implanted the first artificial networking group, the Smart Plastics initiative. The aim of plastic heart. In the 1980s, Dr Slepian developed one of this group is to accommodate the entire value chain for the first prototypes for biodegradable stents. intelligent electronic plastic products within Upper Dr Slepian is director of interventional cardiology and Austria so that world-leading system solutions may be professor of medicine at the USA’s University of Arizona developed in partnership. To further this goal, Smart (UA) Sarver Heart Center with a joint appointment in the Plastics is hosting a congress in Linz, Upper Austria—the UA department of biomedical engineering. He is also co- same place where Engel’s headquarters are—on June founder and chief technical officer of Syncardia. 10-11, 2013. Details of the technology on which this dissolvable electronic device is based—known as transient Editor’s Outlook electronics—were published in a September 2012 copy of Plastic electronics may help designers find an Science, a leading US scientific journal. alternative to conventional membrane keyboards in The paper describes a number of examples of transient medical situations. These membranes attempt to integrate electronic devices, including a system designed to monitor a continuous seal over an interface, but are said to be less and prevent bacterial infection at surgical incisions which than robust in practice and constitute a source of has been successfully demonstrated in rats. The paper was infection in sterile environments like operating theatres. written by Fiorenzo Omenetto, professor of biomedical Thanks to the commitment in Austria for smart plastics engineering at the Tufts School of Engineering in and Engel’s lead in the moulding expertise, observers can Massachusetts. Omnetto worked with researchers at expect product designers to turn to smart plastics for University of Arizona and Northwestern University in improved functionality, aesthetic design, not to mention Illinois. Materials found in conventional integrated circuits the wow factor of a highly sensitive button which requires are used—silicon and magnesium—but in an ultrathin form absolutely no pressure to activate. It takes the phrase “at that is then encapsulated in silk protein, which is the touch of a button” to a whole new level. dissolvable. Device dissolution is reportedly further controlled by sheets of silk protein in which the electronics are supported and encapsulated. Omenetto and his team have discovered how to adjust the properties of silk so that a wide range of degradation times can << Left to right: Michael Fischer, Engel sales be predetermined. manager (technologies), Christoph Lhota, Engel’s head of medical, and Philipp Weissel, Photo Source: CEO of plastic electronic. >> Beckman Institute, University of Illinois and Tufts University. 16/ MPN / NOVEMBER/DECEMBER 2012

- 18. Material Diagnosis | Growing Popularity of Bioresorbable Polymers Bioresorbable Polymers: Patents Growing by 37% a year WORDS | SAM ANSON Bioresorbable polymers are nothing new. They trimethylene carbonate to form poly(glycolide-co- have been used in dissolvable sutures for a trimethylene carbonate), or (PGA-co-TMC). PGA degrades to form glycolic acid. number of years. But according to the United States Patent and Trademark Office database, Compounding, Mechanical Properties and the number of patents referencing Degradation Times bioresorbable and medical grew from 48 in The mechanical properties and degradation time of a bioresorbable device can be tailored to a specific 2005 to 311 in 2011, an average annual growth application by adjusting the molecular weight, crystallinity rate of 37%, or 548% in absolute terms. In the and hydrophilicity of the polymer. This is achieved by last two months, the first fully resorbable drug varying the percentage of polylactide D or L forms, and eluting stent was CE marked for sale in Europe. polyglycolide. Tony Listro, managing director of specialist US medical polymer compounder Foster Delivery Science Here Sam Anson looks at bioresorbable explains: “Compositions with higher hydrophilic and processing considerations while reviewing amorphous structures and a lower molecular weight examples of application success. resorb faster, yet often sacrifice mechanical strength. Conversely, higher crystallinity and molecular weight improve mechanical properties and decrease resorption Bioresorbable polymers, also referred to as rates.” bioresorbable or degradable polymers, are polymer Bone growth additives, such as tricalcium phosphate materials which can be safely absorbed by the body so (TCP) or hydroxyapetite acid (HA) can be melt blended that the materials from which a construction is made into these polymers to enhance bone growth during disappear over time. degradation. Additionally, the low melt temperatures of The following report examines bioresorbables from many bioresorbable polymers allows for melt blending the following perpectives—compounding, mechanical active pharmaceutical ingredients (APIs) for controlled- properties and degradation times; moulding and release drug delivery during degradation. However, extrusion; degradation testing; additive manufacturing of higher molecular weight polymers often require higher resorbable tissue engineering scaffolds; Absorb—the first melt temperatures and thus limit melt blending of some ever resorbable stent; Purac glass fibre composites; APIs with low degradation temperatures. supercritical CO2 sterilisation; and coloration. Twin screw extruders optimise bioresorbable polymer blending, including distribution and dispersion of additives. Polymer Types Due to the high cost of bioresorbable polymers, which can The most common bioresorbable polymer is polylactic often exceed US$1,000 per lb (US$2,200 per kg) and the acid (PLA), also known as polylactide, and is made from a relatively small nature of the implantable applications, small lactide monomer. Generally speaking, PLA is the main scale twin screw extruders—between 16 mm and 27 mm— building block for bioresorbable polymer materials. are ideal. Since these polymers begin degradation when Common derivatives of PLA are poly-L-lactide (PLLA), exposed to moisture, desiccant and vacuum driers are poly-D-lactide (PDLA) and poly-DL-lactide (PDLLA). required prior to melt blending. Unlike non-resorbable When in the body, PLA degrades into lactic acid, a non- polymers that are often water cooled upon exiting the toxic chemical which occurs naturally in the body. extruder in strand form, bioresorbable compounds must Polyglycolic acid (PGA), or polyglycolide (PG), is be air cooled. Pelletised strands destined for finished another type of bioresorbable polymer usually used for device processing must be thoroughly dried and properly bioresorbable sutures. The material can be packaged to prevent exposure to air moisture that can copolymerised with lactic acid to form to form poly(lactic- cause premature degradation. co-glycolic acid), or PLGA, with e-caprolactone to form poly(glycolide-co-caprolactone), or PGCL, and with 18/ MPN / NOVEMBER/DECEMBER 2012

- 19. BIORESORBABLE POLYMERS Moulding and Extrusion Considerations The processing of bioresorbable polymers must be Additive Manufacturing of Resorbable Tissue handled with care. The materials themselves are highly Engineering Scaffolds hydrophilic, which is to say that they love water and will Additive manufacturing is being used to produce absorb any moisture with which they come into contact. scaffolds for tissue engineering from bioresorbable Unless properly dry, the materials will not melt and polymers. A number of years back, researchers from A recrystallise as expected, making moulding and extrusion Star, a leading Singaporean research institution, difficult. At the same time, bioresorbable polymers are successfully developed a technology for fabricating sensitive to heat, and molecular structures can be damaged resorbable polymeric tissue scaffolds with high strength through exposure to excessive temperatures during drying. and porosity using additive manufacturing. Dr Margam With this in mind, careful and thorough drying at low Chandrasekaran (Chandra), now CEO and chief scientist temperatures is needed, while the humidity of the at Singapore-based tissue engineering scaffold processing environment must be considered. manufacturer Bioscaffold International, was one of the Knowing the melt and recrystallisation behaviour of lead inventors of the technology. Along with a team of bioresorbable materials is important, as is understanding clinicians at the National University of Singapore, at A Star the melt flow viscosity. Often materials will have a low Chandra developed an application of the technology to melt temperature, a high crystallisation temperature and produce a commerical product for high strength generally be extremely viscous—like hot honey—except resorbable dental scaffolds using at a small temperature range between the two. This additive manufacturing. means that there is a very small temperature range at Chandra explains: “We which materials can be processed—that is to say, the used a combination of PLGA range at which the material is molten, at which the with PVA and changed the viscosity is at the right level for injection moulding or binder used in the 3D extrusion, and at which the material won’t crystallise printing process to prematurely. produce parts in a Due to their delicate molecular structures, desired shape and bioresorbable polymers are limited in terms of the amount then used a post of time they can remain molten, so cycle times must be processing technique kept within this range, which is often not very long. similar to particulate leaching to strengthen the Degradation Testing of Bioresorbable Medical structure. In fact, besides Devices PLGA, we did work on << The 3D–Bioplotter from On November 28, 2012, the FDA held a public PCL, PLA and PGA. A EnvisionTec is specially designed workshop on the testing of bioresorbable medical paper was published in to process a large range of devices at its White Oak campus in Silver Spring, 2007 in the Journal of materials, from hard polymers, Maryland, USA. Materials Processing and through ceramic pastes to soft The workshop, entitled Workshop on Absorbable Technology.” hydrogels including cells. >> Medical Devices: Lessons Learned From Correlations of Today, Chandra’s Bench Testing and Clinical Performance, was co- company manufactures implantable tissue engineering sponsored by ASTM (American Society for Testing and scaffolds for dentists made from PLGA. The scaffolds are Materials) International, a US organisation responsible for used by dentists to preserve tooth sockets following the development and delivery of international voluntary removal of a tooth. The implant encourages bone growth, consensus standards for engineered products, including thereby preserving the socket while the gums heal. This medical devices. means that any further restorative procedures, such as The purpose of the workshop was to provide a forum dentures or implantable false tooth fittings, are vastly for highlighting and discussing the use of bioresorbable improved. materials in medical devices across a broad range of Another resorbable scaffold application, indications with the aim of defining successful and manufactured in the USA by tissue engineering device unsuccessful methods to predict clinical performance. pioneer 3D Biotek, is a three dimensional PLGA-based The main topics discussed included identification of degradable porous cell culture device for medical test methods for establishing correlations between in research processes. The device is special because its vitro and in vivo degradation of absorbable implantable three dimensional nature allows cells to grow in three devices, and the interaction of mechanical loading and dimensions. Its 100% porous nature allows cells to be mechanical performance with degradation. While there seeded very easily. Because PLGA is biocompatible, the was an emphasis on cardiovascular indications as part of a scaffolds, with or without cells, can be implanted into panel session, characterisation techniques and animals. Degradation time is approximately 4-5 months. experiences from both cardiovascular as well as non- Germany-headquartered 3D printer supplier cardiovascular devices were discussed and encouraged. Continued on page 20 NOVEMBER/DECEMBER 2012 / MPN /19

- 20. BIORESORBABLE POLYMERS Continued from page 19 the degradation rate govern this performance. EnvisionTec’s 3D-Bioplotter is an all-purpose direct The potential long term benefits of a scaffold that manufacturing tissue engineering machine for the dissolves are significant. The vessel may expand and production of hard and soft scaffolds from biomaterials, contract as needed to increase the flow of blood to the cells as well as synthetic materials. It is specially designed heart in response to normal activities such as exercising. to process a large range of materials, from hard polymers, Treatment and diagnostic options are broadened. The through ceramic pastes to soft hydrogels. need for long-term treatment with anti-clotting According to EnvisionTec, the 3D-Bioplotter is medications may be reduced. And future interventions specially designed for work in sterile environments in a would be unobstructed by a permanent implant. laminar flow box, a requirement of biofabrication, for “This innovation represents a true paradigm shift in example when using alginate cell suspensions for the how we treat coronary artery disease,” said Patrick W construction of cell-laden scaffolds. Additionally, the 3D- Serruys, a medical doctor and professor of interventional Bioplotter can use up to five different tools per job. This cardiology at the Thoraxcentre, Erasmus University means that scaffolds fabricated using the 3D-Bioplotter Hospital, Rotterdam, the Netherlands. He added: “With can have up to five different materials, or five different the launch of Absorb, a scaffold that disappears after types of cells in specific positions. doing its job is no longer a dream, but a reality.” In contrast to other rapid prototyping techniques the Absorb is now available in a broad size matrix to 3D-Bioplotter, EnvisionTec says, uses a very simple and support the needs of physicians treating patients with straightforward technology, invented in 1999 at the CAD. There are 7 sizes available—varying in length from Freiburg Materials Research Centre in Germany. The 12 mm to 28 mm and in diameter from 2.5 mm to manufacturing process works by air pressure being 3.5 mm. The strut thickness and width are approximately applied to a liquid and liquefied material, which solidifies 150 μm and 180 μm respectively. upon dispensing. At the time of going to press, Absorb is neither The 3D-Bioplotter is delivered together with a PC approved nor authorised for sale and currently is in workstation which operates and monitors the system. After development with no regulatory status in the United States. transferring the 3D CAD data to the PC it is processed by the Bioplotter’s software package. The preprocessed data << The backbone of is then transferred to the 3D-Bioplotter using a network Absorb, the first connection. The Bioplotter software monitors the working fully resorsable drug process until it is completed. eluting stent, is produced by Abbot Launches First Ever Bioresorbable Vascular extruding PLLA into Scaffold a tube and then USA-headquartered Abbott, one of the world's radially and axially leading medical device OEMs with 91,000 employees, has expanding that tube launched Absorb, the first fully resorbable drug eluting in a process which is vascular scaffold. similar to stretch Absorb is available for use by clinicians in treating blow moulding. The coronary artery disease (CAD) across Europe, Asia Pacific tube is then lasered and Latin America. It works by restoring blood flow to the to produce the heart—similar to a metallic stent—but instead of being scaffold pattern. >> permanent it dissolves into the body. After dissolution it leaves behind a treated vessel that may resume more Bioresorbable Glass Fibre Composites for Load natural function and movement because it is free of a Bearing permanent metallic stent. In August 2012, Netherlands-based bioresorbable In order to create the backbone of the device, PLLA polymer manufacturer and owner of the Purasorb brand resin is extruded into a tube, then radially and axially of medical resorbable polymers Purac acquired FiberLive, expanded in a process that resembles stretch blow an advanced resorbable glass fibre composite technology. moulding. The scaffold pattern is then cut with a laser, and The acquisition included the intellectual property of the the finished product is coated with a drug and polymer FiberLive technology and its key personnel. mixture and crimped onto a catheter before being According to Purac, FiberLive is a unique patented packaged and sterilised. composite consisting of a matrix of resorbable silica- According to Abbott, PLLA has an intrinsic degradation based glass fibres and resorbable polymers, forming an rate that is influenced in vivo by very few factors. Device exceptionally strong resorbable composite material—up performance over its degradation lifecycle is tuned to to six times stronger than cortical bone. This unique match physiological requirements for vessel support. The composite material widens possibilities to use resorbable polylactide molecular weight in the finished product and Continued on page 22 20/ MPN / NOVEMBER/DECEMBER 2012

- 21. NOVEMBER/DECEMBER 2012 / MPN /21

- 22. Material Diagnosis | Growing Popularity of Bioresorbable Polymers Continued from page 20 (PDLLA), polyglycolide (PG), polycaprolactone (PCL)— and copolymers L-lactide/DL-lactide (PLDL), materials into the fields of bone fixation, where in the past L-lactide/D-lactide (PLD), L-lactide/glycolide (PLG), L- it has been impossible due to a lack of load-bearing lactide/captrolactone (PLC) and DL-lactide/glycolide properties of conventional biopolymers. The material can (PDLG). The company also offers custom synthesis of be used in different kinds of orthopaedic treatments, bioresorbable polymers. including craniomaxillofacial (skull and jaw), sports medicine, trauma and spinal procedures. When commenting on the acquisition, Menno << Implantable Lammers, managing director Purac Biomaterials, said: “This resorbable screws technology will be a game changer in the orthopaedic made from Purac resorbable market, where load bearing properties are FiberLive. >> needed. The FiberLive technology is the strongest fully resorbable material available for human implants, with strength up to six times higher than cortical bone, comparable to metal. For decades Purac Biomaterial has been the leading company in the field of medical Supercritical CO2 Sterilisation of Bioabsorbable resorbable polymer materials having strong commitment Polymer Devices and enthusiasm towards innovation and development in A team of researchers at NovaSterilis, a supplier of the field. With the acquisition of this innovative supercritical carbon dioxide (scCO2) sterilisation resorbable composite material we are able to further technologies and equipment based in the state of New widen our capabilities to serve our customers according York, working with Dr Chih-Chang Chu, a professor from to their requirements.” Cornell University (Ithaca, NY), have developed a novel The Purasorb brand of resorbable polymers covers a process for sterilising devices made from bioresorbable broad range of grades, including polymers—poly-L- polymers using scCO2. The technology is being distributed lactide (PLLA), poly-D-lactide (PDLA), poly-DL-lactide in Europe by European Medical Contract Manufacturer 22/ MPN / NOVEMBER/DECEMBER 2012

- 23. BIORESORBABLE POLYMERS (EMCM) based in Nijmegen, The Netherlands. inactive, which means that when the spore is killed, there According to a poster presentation from the team is little or no effect on the delicate surrounding material. displayed at the Ninth World Biomaterials Congress in Sterilisation can be done inhouse as there are low China in June 2012, which reported the feasibility of capital expenditures required, meaning that device NovaSterilis’s scCO2 sterilisation method for an manufacturers can retain full control and sight of their absorbable suture, scCO2 is preferable to ethylene oxide products during sterilisation. Furthermore, the time taken when sterilising bioresorbable devices for a number of for this method is much shorter than traditional ethylene reasons, as follows. oxide—according to NovaSterilis president and CEO Devices can be processed at low pressure and David C Burns, “you are talking minutes to hours rather temperature, which reduces costs and energy requirements. than hours to days”. Low temperature processing makes it ideal for specialist Residual chemicals are non existent or negligible bioresorbable devices due to their highly sensitive following sterilisation. Any that do remain are non-toxic as molecular structure (as explained earlier). Furthermore, the confirmed by toxicity testing. CO2 molecule has a low surface tension which also reduces ScCO2 sterilisation is a new technology. The first 510k the likelihood of damaging delicate molecular structures submission is expected within the next 12 months. Four commonly found in bioresorbable materials. companies are currently using the technology to sterilise The fact that scCO2 sterilisation can be used to allograft tissue because of its gentle effect on collagen sterilise in between the pores of a material—it is said to (biopolymer)—three in the USA and one in Australia. penetrate deeply into a substance—plays perfectly into According to David C Burns, president and CEO the hands of bioresorbable polymer devices as by their NovaSterilis: “Today’s highly technical products require very nature they are very porous. The poster points to very specialised handling, including sterilisation in smaller the fact that spores can live in the pores of the material batches. Moreover, the desire to maintain custody of and the method can get right between the microscopic product is more important to many of our customers.” holes to ensure they are completely sterile. Furthermore, The NovaSterilis scCO2 process is said to be safe for reinforcing the delicate nature of the method, the scCO2 many polymers, allograft tissues, plastics, and surgical can penetrate inside the spore and oxidise it to render it Continued on page 25 NOVEMBER/DECEMBER 2012 / MPN /23

- 25. BIORESORBABLE POLYMERS Continued from page 23 as doxycycline antibiotics and cell growth substances. metals. NovaSterilis manufactures 20-litre and 80-litre fully The process whereby these granules are made is an automated, computerised, and network capable inhouse developed proprietary process of DS. The sterilisation units. Designed with a small footprint, these materials start out as soft porous granules of tricalcium units are ideal for biomedical material companies that phosphate (TCP). Then using a sintering process, the require high value and flexibility. NovaSterilis provides granules are hardened and coated with PLA before being supportive technical services, assisting customers to packaged into easy-to-use kits ready for orthopaedic determine if this process is appropriate for specific surgeons. products, establishing cycle times and developing Tissue fixation implants are injection moulded validation and regulatory plans. degradable PLA-based components for fixing tissue in In 2007 NovaSterilis won the Presidential Green place during surgery. Processed by closely controlling Chemistry Challenge Award Presented by the US cycle times and temperatures, DS manufactures a range of Environmental Protection Agency. devices, including cages for spinal applications, knee interference screws, small pins for foot surgery, implants << This is a highly magnified scCO2 for cranioplasty and suture anchors for shoulders. In this sterilised Dexon suture, area, the company offers full device development and manufactured by USA- manufacturing services, including design and headquartered device development, manufacturing, packaging, sterilisation, manufacturer Covidien. registration as well as development and manufacture of Note the scale—100 μm— the instruments required for application. on the left hand side. The image is courtesy of Dr Coloured Bioresorbables Chih-Chang Chu of Cornell Visibility of small transparent implantable devices can University’s Department be difficult intra operatively. Coloured devices can of Fiber Science and support precision and quality control of the surgeon. Apparel Design. >> Bioresorbable colours are another product offering of DS. The company is an expert at integrating FDA approved Profile of a Bioresorbable Expert: Degradable implantable colours into bioresorbable devices. The issue Solutions, Switzerland with pigments in implantable devices is that there are very Degradable Solutions (DS), based in Switzerland, few suppliers of biocompatible colours. DS has secured manufactures a number of bioresorbable products. The the supply of compliant pigments. company is a spin-off from the Swiss Federal Institute of Technology Zurich (Eidgenössische Technische Hochschule Zürich—ETH) and was taken over in November 2011 by Swiss oral care device manufacturer Sunstar Group. It is a technological leader in its field and has extensive experience of working with bioresorbable polymers. Two areas of interest are bone graft << Degradable Solutions, substitutes and tissue fixation devices. based in Switzerland, has Bone graft substitutes are sold under the brand name developed granules (left) of easy-graft and are the company’s most important resorbable tricalcium product. Easy-graft consists of resorbable granules of phosphate coated with PLA. calcium phosphate which have been coated with When mixed with an polylactic acid. The granules are injected into parts of the activator liquid the granules body where bone needs to grow, particularly broken form a sticky putty which can be injected (above) into bones and teeth. An activator liquid is added to the the body before setting to form a bioresorbable porous granules just before injection. The activator causes the bone cement that allows bone to grow in and around it polylactic acid coatings to form a sticky putty which allows as it degrades slowly over time. >> the granules to be applied directly through a syringe. When in contact with blood, the biomaterial solidifies << Degradable Solutions is and forms a defect-analogue, mechanically stable mass of also an expert injection material which is porous and will be replaced by bone moulder of resorbable tissue over time. materials. This screw, This occurs thanks to the fact that the calcium Sysorb, is a patented phosphate degrades over time, allowing bone cells to turbine shaped screw head grow in and around the calcium phosphate granules as for reconstruction of the they degrade. DS is also talking about incorporating cruciate ligament. >> active pharmaceutical ingredients into the material, such NOVEMBER/DECEMBER 2012 / MPN /25