Ganesan Plant Inspector_CV

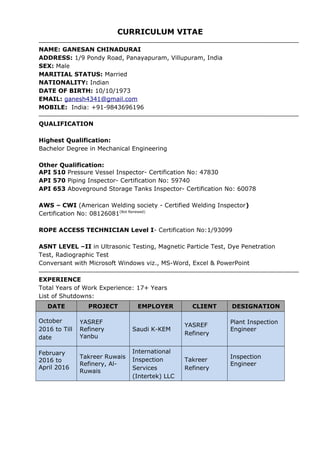

- 1. CURRICULUM VITAE NAME: GANESAN CHINADURAI ADDRESS: 1/9 Pondy Road, Panayapuram, Villupuram, India SEX: Male MARITIAL STATUS: Married NATIONALITY: Indian DATE OF BIRTH: 10/10/1973 EMAIL: ganesh4341@gmail.com MOBILE: India: +91-9843696196 QUALIFICATION Highest Qualification: Bachelor Degree in Mechanical Engineering Other Qualification: API 510 Pressure Vessel Inspector- Certification No: 47830 API 570 Piping Inspector- Certification No: 59740 API 653 Aboveground Storage Tanks Inspector- Certification No: 60078 AWS – CWI (American Welding society - Certified Welding Inspector) Certification No: 08126081(Not Renewed) ROPE ACCESS TECHNICIAN Level I- Certification No:1/93099 ASNT LEVEL –II in Ultrasonic Testing, Magnetic Particle Test, Dye Penetration Test, Radiographic Test Conversant with Microsoft Windows viz., MS-Word, Excel & PowerPoint EXPERIENCE Total Years of Work Experience: 17+ Years List of Shutdowns: DATE PROJECT EMPLOYER CLIENT DESIGNATION October 2016 to Till date YASREF Refinery Yanbu Saudi K-KEM YASREF Refinery Plant Inspection Engineer February 2016 to April 2016 Takreer Ruwais Refinery, Al- Ruwais International Inspection Services (Intertek) LLC Takreer Refinery Inspection Engineer

- 2. October 2015 to November 2015 Nigerian LNG plant, Bonny Island RusselSmith Group - Lagos, Nigeria Nigerian LNG (LNGN) API Inspector with Rope Access Inspector September 2015 to October 2015 S-Chem Bisco Integrated Service Jubail Saudi Chevron Phillips Company Inspection Engineer August 2015 to September 2015 Nigerian LNG plant, Bonny Island RusselSmith Group - Lagos, Nigeria Nigerian LNG (LNGN) API Inspector with Rope Access Inspector April 2015 to May 2015 YANSAB Petrochemical Company Yanbu Bisco Integrated Service Jubail KSA SABIC Plant Inspector (Static Equipment) Feb 2015 to March 2015 Qatar Gas II Train 4 Emirates Industrial Laboratory (EIL-DPIS) Qatar Gas Plant Inspector (Static Equipment) January 2015 to Feb 2015 Oman Methanol Company International Inspection Services (Intertek) LLC Oman Methanol Company Plant Inspector September 2014 to October 2014 Qatar Gas II Train 5 Oceaneering Qatar Gas Plant Inspector (Static Equipment) January 2014 to April 2014 Qatar Petroleum NGL - 1 Shutdown & In-service Inspection BUREAU VERITAS Qatar Petroleum Plant Inspector (Static Equipment) June 2013 to December 2013 CPCL Unit - I AMS ENGINEERING PVT LTD Chennai Petroleum Corporation Ltd Plant & equipment Inspector February 2013 to April 2013 Qatar Petroleum NGL - 2 BUREAU VERITAS Qatar Petroleum Plant Inspector (Static Equipment) July 2012 to CPCL Unit - II AMS Chennai Plant & equipment

- 3. December 2012 ENGINEERING PVT LTD Petroleum Corporation Ltd Inspector February 2012 – April 2012 Qatar Petroleum NGL - 1 BUREAU VERITAS Qatar Petroleum Plant Inspector (Static Equipment) October 2011 to December 2011 ENOC Dubai Topaz Engineering Emirates Petroleum Corporation Ltd (EPCL) Plant Inspector April 2011 to July 2011 TUV Rheinland Arabia LLC (TURA) Petrochemical & Refinery plant TUV Rheinland Arabia LLC (TURA) Petrorabigh, Saudi Arabia Plant Inspector Summary • Having more than 17 years of Inspection experience covering Mechanical, pressure vessels, piping, Modules, Structural, tanks, welding, painting, coating, and insulation in Offshore, Onshore installations both in new construction as well as in maintenance inspection. • Inspection of Oil & Gas field and Petrochemical plant static equipments and associated piping in on-stream, maintenance, shutdown and ATA inspection. • Inspection of all types of Oil & Gas, refinery, Off-shore and petrochemical plant static equipments (columns, drums, heat exchangers, storage tanks and piping) and to compiles written reports on its findings and recommendations puts in repair recommendations to user departments. • Keeping all inspection equipment history files up-to-date and also keeps on- stream inspection data current. • Inspects the structure modification for Oil & gas field, Off-shore and Petrochemical plant static equipments and associated pipings, supports etc., in accordance with company procedures / specifications. • Advises and recommends required repairs or replacements to defective Oil & Gas field, Off-shore and Petrochemical plant static equipments and carries out further inspection after repair work to ensure conformity to approved standards and codes. • Direct, advice and instruct NDT Technicians in the recommends of specific examination and performance of routine duties, evaluate inspection and NDT results and prepare reports with recommendation regarding potential repairs, fitness for service and anticipated equipment residual life. • Extensive quality management experience in the oil and gas, offshore modules within multi-nationality work environments. • Possess good interpersonal skills combined with the ability to communicate at

- 4. all levels together with a flexible ‘hands on’ approach to problem solving, whilst retaining a strong management approach to both safety and quality. • Review of ITP, Vendor documents (WPS/PQR, NDT and other testing procedures) and review of Inspection reports. • Pre-Inspection meeting and Kick off meeting with Vendor along with Client for the ordered items. • Coordination with Client / Vendors / Inspection agencies. • Document/ data control/ corrective/preventive action for all NCR/ customer complaints. • Excellent exposure in the codes of ASME, ASTM, ANSI, API, AWS • Worked in UAE, Saudi Arabia, Kuwait, Qatar, Angola, Malaysia, Indonesia and Singapore EXPERIENCE DETAILS October 2016 to Till date YASREF Refinery, YANSAB, Plant Inspection Engineer • Conduct on-stream inspection on the plant stationary equipment including pressure vessels, heat exchangers, drums, storage tanks, filters, column according to Company established policies and procedures and issues inspection reports. • Inspection rerating activities for pressure vessels and the pressure relieving devices protecting these vessels. • Corrosion Under Insulation (CUI) Inspections. • Post Weld Treatment (PWT) Inspections. • Inspection of all types of Steam coils, headers and crossovers in accordance with the requirements of the ASME and to compiles written reports on its findings and recommendations puts in repair recommendations to user departments. • Inspection of all types of plant static equipments columns, drums, heat exchangers, storage tanks, fin-fan cooler and filters • REFORMER welds of inlet and outlet pigtails, Root pass of butt welds joining, Weld activities February 2016 to April 2016 Takreer Refinery, Al-Ruwais, Inspection Engineer • Inspection of all types of Steam coils, headers and crossovers in accordance with the requirements of the ASME and to compiles written reports on its findings and recommendations puts in repair recommendations to user departments. • Inspection of all types of plant static equipments columns, drums, heat exchangers, storage tanks, fin-fan cooler and filters • REFORMER welds of inlet and outlet pigtails, Root pass of butt welds joining, Weld activities October 2015 to November 2015 RusselSmith Group, Lagos, Nigeria, API Inspector/Rope Access Inspector

- 5. • Taking the technical lead on a daily basis, regarding all inspection work related to area such as pipe line, vessels, tank and platform inspections. • Provide daily direction to sub-ordinate Inspectors and/or NDE Technicians assigned. • Oversee daily inspection activities. Routine audits of inspection and non- destructive examination activities. • Write/review inspection reports, plans, repair recommendations and other inspection documents. • Using industrial rope access services in difficult to access areas such as confined spaces and high access areas. • Develop and implement area equipment inspection and testing plans for compliance and turnarounds. • Implement all the applicable procedure which is applicable to client including HSE. • Assist in recruiting and training personnel on operational functions; conduct safety orientations and meetings; assures that established policies and procedures are followed. • Verify that the integrity of the structure has been restored for the purpose it was designed for. September 2015 – October 2015 Bisco Integrated Service Jubail KSA, S-CHEM (Saudi Chevron Phillips Company), Plant Inspection Engineer • Review of contractor’s documents related to quality and inspection. • Conducting Pre Inspection Meeting to ensure compliance of planned activities as per the project requirements, Clarifications, Fulfilment of requirement as per the Approved Drawings, Code/Standards and Project specifications. • Inspection of pressure vessels as per approved Inspection and Test Plan (ITP) • In Plant inspection of Pressure Equipments, witnessed Tests, Checked welding condition (external and internal), Visual inspection of Equipments associated with piping systems, Preparation and submission of daily reports, Recommended repair procedures for defects noticed during inspection, coordination with Client for inspection related activities and assisted in the compilation of final QC documentation. • Stage inspection and Final inspection / NDT witness, IWL and review, Hardness test/ Positive Material Identification. August 2015 to September 2015 RusselSmith Group, Lagos, Nigeria, API Inspector/Rope Access Inspector • Taking the technical lead on a daily basis, regarding all inspection work related to area such as pipe line, vessels, tank and platform inspections. • Provide daily direction to sub-ordinate Inspectors and/or NDE Technicians assigned. • Oversee daily inspection activities. Routine audits of inspection and non- destructive examination activities. • Write/review inspection reports, plans, repair recommendations and other inspection documents. • Using industrial rope access services in difficult to access areas such as confined spaces and high access areas. • Develop and implement area equipment inspection and testing plans for

- 6. compliance and turnarounds. • Implement all the applicable procedure which is applicable to client including HSE. • Assist in recruiting and training personnel on operational functions; conduct safety orientations and meetings; assures that established policies and procedures are followed. • Verify that the integrity of the structure has been restored for the purpose it was designed for. April 2015 to May 2015 Bisco Integrated Service Jubail KSA, YANSAB Petrochemical Company (SABIC) Yanbu, Plant Inspector • Conduct on-stream inspection on the plant stationary equipment including pressure vessels, heat exchangers, drums, storage tanks, filters, column according to Company established policies and procedures and issues inspection reports. • Inspection rerating activities for pressure vessels and the pressure relieving devices protecting these vessels. • Corrosion Under Insulation (CUI) Inspections. • Post Weld Treatment (PWT) Inspections. • Carry out As found inspection, intermediate and final inspections. • Hydro test and leak test inspections. • Inspects and assesses the condition of Plant static equipments at the required frequency in accordance with the company's procedure and code requirements. • Fit-for-assessment of Pressure vessels, Pressure piping, Storage tanks as per relevant API / ASME codes. 27th February 2015 to March 2015 Emirates Industrial Laboratory (EIL-DPIS), Qatar Gas II Train 4, Plant Inspector • Inspection scheduling based on criticality rating, corrosion looping and history of all static equipment. • Inspection rerating activities for pressure vessels and the pressure relieving devices protecting these vessels. • Corrosion Under Insulation (CUI) Inspections. • Post Weld Treatment (PWT) Inspections. • Carry out As found inspection, intermediate and final inspections. • Inspection of all types of plant static equipments (columns, drums, heat exchangers, storage tanks, fin-fan cooler and filters) and to compiles written reports on its findings and recommendations puts in repair recommendations to user departments. • Carry out Hydro test and leak test inspections. • Inspects and assesses the condition of Plant static equipments at the required frequency in accordance with the company's procedure and code requirements. • Fit-for-assessment of Pressure vessels, Pressure piping, Storage tanks as per relevant API / ASME codes.

- 7. January 2015 to Until 10th February 2015 International Inspection Services (Intertek) LLC, Oman Methanol Company, Sohar, Oman, Plant Inspector • Inspection of all types of Steam coils, headers and crossovers in accordance with the requirements of the ASME and to compiles written reports on its findings and recommendations puts in repair recommendations to user departments. • Inspection of all types of plant static equipments columns, drums, heat exchangers, storage tanks, fin-fan cooler and filters • REFORMER welds of inlet and outlet pigtails, Root pass of butt welds joining, Weld activities • Inspection of Package Boiler internal and external • All pressure containing welds including attachment welds of couplings • Inspection of Pressure vessels, Storage tanks as per relevant API / ASME codes. September 2014 to October 2014 Oceaneering, Qatar Gas II Train 5, Plant Inspector • Inspection scheduling based on criticality rating, corrosion looping and history of all static equipment. • Carry out As found inspection, intermediate and final inspections. • Inspection of all types of plant static equipments (columns, drums, heat exchangers, storage tanks, fin-fan cooler and filters) and to compiles written reports on its findings and recommendations puts in repair recommendations to user departments. • Carry out Hydro test and leak test inspections. • Inspects and assesses the condition of Plant static equipments at the required frequency in accordance with the company's procedure and code requirements. • Fit-for-assessment of Pressure vessels, Pressure piping, Storage tanks as per relevant API / ASME codes. January 2014 to April 2014 BUREAU VERITAS, Qatar Petroleum, Plant Inspector, NGL - 1 Shutdown & on-stream Inspection • Conduct on-stream inspection on the plant stationary equipment including pressure vessels, heat exchangers, drums, storage tanks, filters, column according to Company established policies and procedures and issues inspection reports. • Implement the computerized inspection program using SAP through Validation of the asset registry, equipment details and the inspection results. • Conduct fitness for service assessment for the different equipment, set the scope of corrective action, set and implement the quality control scope and testing. • Inspects plant stationary equipment by entering into vessels, boilers during shutdowns, to check condition of equipment. Includes noting observations on cracks, pits, thinning and any other pattern of erosion, corrosion and other interior failure. Makes interpretations of findings, analyses for failure,

- 8. prepares report and issues recommendation. • Coordinates with the Operations Planning and Maintenance supervisors such activities as the scheduling and planning of inspections, obtaining the requisite permits and performing any required scheduled equipments. • Checks condition of safety relief valves, and reports findings to supervisor. Witnesses pressure setting before and after repair and during any re- calibration campaign, as assigned. • Prepares report, schedules testing frequency as per policy, enters inspection data in Lyods Register (CAPESTONE) based computerized system, raises recommendation based on valve condition and follow up. • Witness hydrostatic tests and pneumatic tests on pressure equipment. June 2013 to December 2013 AMS ENGINEERING PVT LTD, Chennai Petroleum Corporation Ltd, Plant and equipment Inspector • Looked after executing Inspection Plans, Inspection of Pressure Equipments and Piping systems, witnessed Tests, Checked welding condition (external and internal), Visual inspection of Equipments and Piping systems, Preparation and submission of daily reports, Recommended repair procedures for defects noticed during inspection, coordination with Client for inspection related activities and assisted in the compilation of final QC documentation. • External inspection of weld seams, support structures for any corrosion, foundation structures for any cracks/spalling nozzles, valves and other structural works. February 2013 to April 2013 BUREAU VERITAS, Qatar Petroleum, Plant Inspector, NGL - 2 Shutdowns • Inspection scheduling based on criticality rating, corrosion looping and history of all static equipment. • Inspection of all types of plant static equipments (columns, drums, heat exchangers, storage tanks, fin-fan cooler and filters) and to compiles written reports on its findings and recommendations puts in repair recommendations to user departments. • Inspects and assesses the condition of Plant static equipments at the required frequency in accordance with the company's procedure and code requirements. • Fit-for-assessment of Pressure vessels, Pressure piping, Storage tanks as per relevant API / ASME codes. July 2012 to December 2012 AMS ENGINEERING PVT LTD, Chennai Petroleum Corporation Ltd, Plant and equipment Inspector • Static equipment preliminary inspection and post inspection and NDT review. Checked welding condition (external and internal), Visual inspection of Equipments and Piping systems, Preparation and submission of daily reports, Recommended repair procedures for defects noticed during inspection, coordination with Client for inspection related activities and assisted in the compilation of final QC documentation. • Ensure equipment integrity of static equipment such as vessels, heat exchangers, furnaces, fin-fan coolers, steam boiler and process piping.

- 9. • Supervise process plant inspection activities, NDT techniques, and high pressure welding practices. February 2012 – April 2012 BUREAU VERITAS, Qatar Petroleum, Plant Inspector, NGL - 1 Shutdowns • Pressure vessels inspection, repair monitoring of caustic vessels and Flare Knockout Drums. • Utility Boiler Drums Inspection. • In service inspection of process equipement, piping and Above ground Storage tanks and Double deck floating roof. • Roof and shell course Dismantling and reconstruction of Above Storage tank inspection. • Selection and establishing TML & CML and continuous monitoring the locations. • Retirement thickness calculation, corrosion rate calculation, remaining service life calculation for process piping systems and advising for any repairs/replacement/re-rating requirements. October 2011 to December 2011 Emirates Petroleum Corporation Ltd (EPCL), Plant QC Inspector, Dubai. • Plans, supervises and implements inspection activities on Pressure Vessels, Piping, Tanks and Structural in the On-shore. • Carries out detailed technical assessment of equipment and material specifications to ensure conformity with appropriate construction codes and practices. Specifies inspection and testing requirements. • Supervises inspection programs and reviews/evaluates inspection reports and test results. • Recommends action on the basis of plant condition. April 2011 to July 2011 TUV Rheinland Arabia LLC (TURA) Petrochemical & Refinery plant, Petrorabigh, Plant Inspector, Saudi Arabia • Analyses and monitors on-stream inspection data and carries out condition assessment, and general calculation for corrosion rates and remaining service life of equipment. • Final weld Visual, Dimensional, Hydro testing Inspection of Vessels as per approved Drawings, Approved Procedure, Code/Standard & project Specification. Document, Data Control, Record Maintenance, Document Updating, Report Preparation, Project Monitoring, Coordination with Contractor and Subcontractor and subcontractor Corrective and Preventive actions Subcontractors Procedure Review to ensure fulfilment of requirements with respect to the Reference/Construction Codes and project Specifications. • Selection of an appropriate inspection/NDT techniques as per codes/standards and specification. • Supervision of a team of inspectors & multi-disciplined NDT personnel to complete client inspection program. • Review/ approve Inspection & Test Plans and QA/QC Procedures. April 2010 to February 2011 China Harbour Engineering Company Marine Facilities, Angola LNG Project, Welding Inspector-Structural, Soyo, Luanda, Angola • Approval of QAP with the reference to the technical specification.

- 10. • Responsible for material identification – review of material test certificate with relevant standard specification. • Approval of Procedure & performance qualification. • Stage inspection-fit ups at various stages of Welding • NDT Technique Approval, Review and witness and evaluation of NDT (radiography, ultrasonic, magnetic particle and dye penetrant test). • Review of Post weld heat treatment & hardness reports. • Witnessing hydrostatic & pneumatic test. • Preparing Final documents for the clearance of the job. • Review the WPS and PQR & NDT procedures • Performing welder qualification as per ASME SEC IX • Conducting all NDT, Mechanical, QC inspection and creating inspection records and getting singed from all relevant parties and sending properly to document or record control department April 2009 to September 2009 Consolidated Construction Company (CCC), Khursaniyah Gas Plant, Welding Inspector-Aramco Approved, Saudi Arabia • Implement the Project construction Quality Program (Project Quality control procedures, inspections and test plans, and construction procedures) at site Implement the Quality control intervention points on the Inspection and Test Plans (ITP) • Witnessed Qualification of Welding Procedure Specification and Procedure Qualifications as per ASME SEC.IX and API 1104 Witnessing the Qualification test of welders, welding operators and selection of filler metals as per ASME SEC. IX • Review sub-contractors Quality control procedures and plans. Implement the Surveillance Inspection program over subcontractors to ensure conformity to project specifications/standards • Carry out Quality control activities including inspection, examination and testing to verify the quality of the Installations and ensure construction operations are in compliance with project specifications. • Complete relevant forms and prepare Request for Inspection (RFI), Checklists, reports on inspections and test undertaken for the conclusion in and inspection records. January 2007 to September 2008, Setsco Service Pvt ltd, QA/QC Inspector, Singapore Shut-down Project Attended: Shell, Exxon Mobil, Power Seraya, Chevron, Foster Oil and Gas Energy, Singapore Aerospace Ltd. • Job order review for the fabrication of piping system. • Verification of raw Materials and Welding Consumables. • To inspect various types of weld joint preparation, fit-up, Welder Qualification Test (WQT), Welding Procedure Qualification Test (WPQ) using various Code, Standard, Specification & drawings. • Familiar with and understand fundamental of the following process SMAW / GTAW / FCAW / / GMAW and SAW. • Coordinating with customer representatives, 3rd party inspectors, external agencies as inspection point. • Attended numerous shut downs in ON-PLOT as well as in Flow Lines. Interpretation of RT films and review of the report .

- 11. • Preparing NDE documents for external agencies. Organise, Witness & Review NDT Reports. Check and record welding parameters and verify compliance with approved WPS. • Visual Inspection of fabricated components. June 2004 to November 2006 Poly NDT Pvt Ltd, QC Engineer, Singapore New Construction / Modification Project Attended: Keppel Offshore, Sembcorp Marine Ltd, Jurong Shipyard, PPL Shipyard, Wartsila, Tide Water. • QC Inspector (Welding & NDT) in Fabrication of steel structure for Building and Piping support, construction of pipelines in the transportation of oil and gas as sub-contractor. • Ensuring adherence to contract specification, applicable quality plans, quality Control procedures. • Monitoring of welding parameters for compliance with WPS, Weld mapping. Inspection of painting work. Coordination with NDT agencies and Third party Inspection agencies. May 2002 to April 2004 Royscon Engineering pvt ltd, QC Inspector, Singapore New Construction/Modification Project Attended: Saipem, South East Asia, GE, Halliburton FPSO 4, Nexus Floating Production Ltd. • Inspection of piping structures, pipelines. • Inspection before, during and after welding of pipeline work. • Preparation and Execution of WPS and Welder qualification test. • Monitoring welding parameters for compliance with WPS. • Coordination with NDT agencies. • Organizing and coordination with customer inspection. February 1999 to March 2001 BIT Inspection Technology, Welding Inspector, India • Preparation and Execution of Welding Procedures and Welders performance test. Verification of Group manufacturing System and Drawings. • Monitoring welding parameters and check its compliance with WPS. • Coordinate with customer / Third party inspection agencies. • Preparation of Dimensional report and Inspection Report. January 1996 to January 1999 M/s. Vasan Engineering Industry (P) LTD, QC Inspector, India • Inspection of raw materials, Production and Inspection during and after completion of job. • Follow – up at the sub – contractor’s end. • Coordination during customer Inspection. • Coordinating for material inspection, consumable, tools and equipments etc with relevant document. If required, perform mechanical test and chemical analysis in order to confirm the material as per project specification. • Preparation of WQT and Test document. REFERENCES: Available on Request