Mechanical Engineer Resume

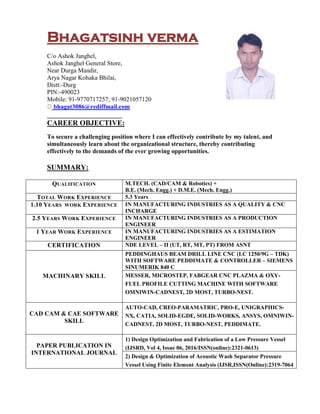

- 1. Bhagatsinh verma C/o Ashok Janghel, Ashok Janghel General Store, Near Durga Mandir, Arya Nagar Kohaka Bhilai, Distt:-Durg PIN:-490023 Mobile: 91-9770717257; 91-9021057120 bhagat3086@rediffmail.com CAREER OBJECTIVE: To secure a challenging position where I can effectively contribute by my talent, and simultaneously learn about the organizational structure, thereby contributing effectively to the demands of the ever growing opportunities. SUMMARY: QUALIFICATION M.TECH. (CAD/CAM & Robotics) + B.E. (Mech. Engg.) + D.M.E. (Mech. Engg.) TOTAL WORK EXPERIENCE 5.3 Years 1.10 YEARS WORK EXPERIENCE IN MANUFACTURING INDUSTRIES AS A QUALITY & CNC INCHARGE 2.5 YEARS WORK EXPERIENCE IN MANUFACTURING INDUSTRIES AS A PRODUCTION ENGINEER 1 YEAR WORK EXPERIENCE IN MANUFACTURING INDUSTRIES AS A ESTIMATION ENGINEER CERTIFICATION NDE LEVEL – II (UT, RT, MT, PT) FROM ASNT MACHINARY SKILL PEDDINGHAUS BEAM DRILL LINE CNC (LC 1250/9G – TDK) WITH SOFTWARE PEDDIMATE & CONTROLLER – SIEMENS SINUMERIK 840 C MESSER, MICROSTEP, FABGEAR CNC PLAZMA & OXY- FUEL PROFILE CUTTING MACHINE WITH SOFTWARE OMNIWIN-CADNEST, 2D MOST, TURBO-NEST. CAD CAM & CAE SOFTWARE SKILL AUTO-CAD, CREO-PARAMATRIC, PRO-E, UNIGRAPHICS- NX, CATIA, SOLID-EGDE, SOLID-WORKS, ANSYS, OMNIWIN- CADNEST, 2D MOST, TURBO-NEST, PEDDIMATE. PAPER PUBLICATION IN INTERNATIONAL JOURNAL 1) Design Optimization and Fabrication of a Low Pressure Vessel (IJSRD, Vol 4, Issue 06, 2016/ISSN(online):2321-0613) 2) Design & Optimization of Acoustic Wash Separator Pressure Vessel Using Finite Element Analysis (IJSR,ISSN(Online):2319-7064

- 2. EXPERIENCE: Period : Jan 2015 to Till Now Organization : Ferro Metals Bhilai Designation : Quality & CNC Incharge Carryout Inward material inspection of raw materials & consumables. Preparation of documents like QAP, WPS, PQR, WPQ, MIR, DR, UT, DP, Painting report and NCR. Dimension Inspection of various structural components and also various equipment as per the given drawing and standards. Carry out welding inspection as per AWS D1.1M & ASME Sec. IX Standards. Carryout the surface preparation and painting inspection. Detailed study of fabrication drawings & documents, Inspect structural assemblies as per procedures and specification. It includes marking, set-up, weld visual/special welding measures and final dimension inspection of all equipment & structures. Understanding of customer requirements, codes & other planning & Welding related documents Planning daily activities and manpower handling. Ensuring smooth job progress and maintaining schedule for timely completion of job. Planning of welding activities for ongoing projects. Developing new welding procedure. Shop weld plan preparation and solving welding related problem in shop. Ensure correct material and electrode selection, specifically for the joining of dissimilar materials. Ensure clean environments procedures were maintained. Monitor pre and post weld heat treatments. Ensure NDT requirements are preformed to specification. Test plan preparation and quality check of welding Establishing of job related QA & QC Procedures. Inspection of fit-up of components including pressure vessels, piping, structural members, nozzles, fittings, and its clearance for welding. Inspection of material with respective to relevant material standard and ensuring that all materials are meeting the requirements of customer. Reviewing of all welding procedures and ensuring that proper WPS is used on the job. Visual examination of all welds and carrying out proper NDT as per customer approved NDT plan. Carrying out all stage wise inspection activities in the ongoing job, and ensuring that all the operations being carried out in the site are as per approved standards and codes. Ensuring that welders are properly qualified and proper consumables are used in the job. Attending Quality Review Meeting regularly, and exploring the solution for the site oriented problems Co-ordination with Third Parties.

- 3. Preparing necessary reports and reviewing with Third Parties and client Representatives to clear the job. Follow up with all concerned procurement deptt. for the clearance activities. To make the cutting-plan & all type development with the help of AUTO CAD SOFTWARE. To make the CNC CUTTING PROFILE PROGRAMMING with help of NESTING SOFTWARE. To handle the CNC PLAZMA & OXY-FUEL CUTTING PROFILE MACHINE (MESSER,HYPER-THERM & FEBGEAR MACHINE) To make the CNC PROGRAMMING & also handle the PEDDINGHAUS BEAM DRILL LINE CNC (LC 1250/9G – TDK) WITH SOFTWARE PEDDIMATE & CONTROLLER – SIEMENS SINUMERIK 840 C EXPERIENCE: Period : July 2012 to December 2014 Organization : Beekay Engineering Corporation Bhilai Designation : Production Engineer GENERAL INFORMATION: Beekay Engineering Corporation has complete Infrastructure, Resources and In-built facilities to undertake manufacture of supply of major equipment & spares for core industries like Steel Plants, Power Plant, Sponge Iron & various Public & Private Clients. JOB RESPONSIBILITIES: To study and understand the drawings of allotted work-orders. To make the Planning-sheet of the work-order after going through its drawings. To make the cutting-plan & all type development with the help of AUTO CAD SOFTWARE. To calculating the raw material requirement as per drawing To reduce the wastage, scrap by effective planning and by full utilization of resources To make the CNC CUTTING PROFILE PROGRAMMING with help of NESTING SOFTWARE. To allot the drawings to the supervisor in the order of their manufacturing. To inspect the fitting as per manufacturing drawing. To inspect the welding quality and other possible defects. To analysis the Welding-Defect and repair planning. Generate Monthly Production Plan as per priority and close monitoring on daily basis. Handling customer complaints and to prepare corrective and preventive action plan to Reduce the customer Complaints. To achieve production target by full utilization of resources. To Overall Responsibility of Production and arrange the Materials as per the Production Plan. Effective manpower planning to achieve the production target. To handle the CNC PLAZMA & OXY-FUEL CUTTING PROFILE MACHINE (MESSER & FEBGEAR MACHINE) To Operate the Industrial Finance System (IFS 7.5).

- 4. EXPERIENCE: Period : June 2011 to July 2012 Organization : Simplex Castings Limited Bhilai Designation : Estimation Engineer (Mechanical Equipment & Project) JOB RESPONSIBILITIES: Preparation of cost estimation for the scope of work in line with the tender requirements. Prepare shop drawing for fabrication. Evaluating the tender documents, BOQ, drawings & specification. Preparing enquiries to receive quotation for the materials, services, subcontract works for the preparation of estimation. Comparison studies based on supplier’s quotation. Preparing Techno – commercial proposal in compliance with the client requirements specified in the RFQ. Maintaining ISO documentation, record keeping, and suppliers / manufacturers data bank record. Preparing drawings for the proposals & the approvals. Making Pre – Qualification documents, Certificates as per project specifications. Visual inspection of welds and perform failure – cause analysis. Records and endorse reports of inspection and test witness and compile scope files to identity statues. Witness & Certify Hydro test, Pneumatic tests, Mechanical tests like Tension test, bend test, Impact & Hardness tests. Review of welding procedures specifications (WPS & PQR) ,witness and approve welder / welding operator performance qualification (WPQ) Review Test certificates with respect to standards / specification. All raw material inspection and their MTC review according to specification requirements. Preparation of Method statements for various installations in coordination with senior engineers and construction in charges Ensuring the use of sound construction practices to attain required quality control Ensuring maximum efficiency to enable delivery of the project on time and within the budget.

- 5. Academic Profile: SOFTWARE SKILL: CAD: - AUTO-CAD CREO-PARAMATRIC PRO-E CATIA UNIGRAPHICS NX SOLIDWORKS SOLID EDGE CAM: - CREO-PARAMATRIC PRO-E WILDFIRE UNIGRAPHICS NX PADDIMATE CAE:- ANSYS (Solving All Type Mechanical Analysis) NESTING:- Omniwin Cadnest Most 2D TURBONEST CONTROLLER:- SIEMENS SINUMERIK 840 C Educational Degree College/School Name University/Board Year of Completion Division M.Tech. (CAD/CAM & Robotics) Christian College of Engineering & Technology Bhilai CSVTU Bhilai 2016 First Class B.E. (Mechanical Engineering) St. Vincent Pallotti College Of Engineering & Technology Nagpur RTMNU Nagpur 2011 First Class Diploma In Mechanical Engineering Vivekanand Polytechnical Sitasaongi MSBTE Mumbai 2007 First Class Higher Secondary(10+2) (HSSC) R.S.G.K. Agrawal Junior college,Tumsar Nagpur 2004 Second Class High School (10th ) (SSC) Buti Vidyalay Gobarwahi Nagpur 2002 First Class

- 6. OTHER:- MS-OFFICE Industrial Finance System (IFS 7.5). PAPER PUBLICATION: Design Optimization and Fabrication of a Low Pressure Vessel (IJSRD, Vol 4, Issue 06, 2016/ISSN(online):2321-0613) Design & Optimization of Acoustic Wash Separator Pressure Vessel Using Finite Element Analysis (IJSR,ISSN(Online):2319-7064 CERTIFICATION: ASNT (NDE) LEVEL – II (UT, RT, MT, PT) MACHINARY SKILL : MESSER, MICROSTEP, FABGEAR CNC PLAZMA & OXY-FUEL PROFILE CUTTING MACHINE – To make the programming by using Omniwin Cadnest, Turbo Nest, Most 2D Software & also handle the operation. PEDDINGHAUS BEAM DRILL LINE CNC (LC 1250/9G – TDK) WITH SOFTWARE PEDDIMATE & CONTROLLER – SIEMENS SINUMERIK 840 C – To make the programming by using peddimate software & also handle the operation Key Strength: 1. Positive attitude. 2. A good listener. 3. Able to perform under pressure. 4. Ability to work well in team. Extracurricular Activities: 1. Has passed NCC C-Certificate 2. Has participated in athletics at university level. 3. Has won 1st prize in football at district level HOBBIES & INTERESTS: 1. Studying. . 2. Solving Problems & also Learning the Design Software. 3. Traveling. 4. Playing.

- 7. PASSPORT DETAILS: Passport No. : J6019888 Place of Issue : NAGPUR Date of Issue : 25/02/2011 Date of Expiry: 24/02/2021 PERSONAL DETAILS: Father's Name : Jagdish Verma Mother's Name : Kamala Verma Date of Birth : 30th AUG. 1986 Gender : Male Marital status : Unmarried Linguistic Ability : English, Hindi, Marathi, Chhattisgarhi. Nationality : Indian Declaration: I hereby declare that the above written particulars are true to the best of my knowledge and belief. Date: - ………………. Place: - ………………. Bhagatsinh Verma