Ashok_Patel_Resume_latest

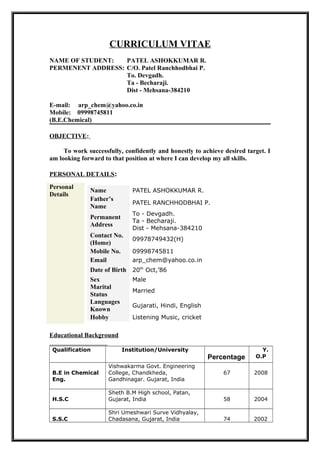

- 1. CURRICULUM VITAE NAME OF STUDENT: PATEL ASHOKKUMAR R. PERMENENT ADDRESS: C/O. Patel Ranchhodbhai P. To. Devgadh. Ta - Becharaji. Dist - Mehsana-384210 E-mail: arp_chem@yahoo.co.in Mobile: 09998745811 (B.E.Chemical) OBJECTIVE: To work successfully, confidently and honestly to achieve desired target. I am looking forward to that position at where I can develop my all skills. PERSONAL DETAILS: Educational Background Qualification Institution/University Percentage Y. O.P B.E in Chemical Eng. Vishwakarma Govt. Engineering College, Chandkheda, Gandhinagar. Gujarat, India 67 2008 H.S.C Sheth B.M High school, Patan, Gujarat, India 58 2004 S.S.C Shri Umeshwari Surve Vidhyalay, Chadasana, Gujarat, India 74 2002 Personal Details Name PATEL ASHOKKUMAR R. Father’s Name PATEL RANCHHODBHAI P. Permanent Address To - Devgadh. Ta - Becharaji. Dist - Mehsana-384210 Contact No. (Home) 09978749432(H) Mobile No. 09998745811 Email arp_chem@yahoo.co.in Date of Birth 20th Oct,’86 Sex Male Marital Status Married Languages Known Gujarati, Hindi, English Hobby Listening Music, cricket

- 2. WORKING EXPERIENCE: Currently working in Lubrizol Advanced Materials India Pvt Ltd, Dahej as a Senior Executive from 01 June-2015. Worked in BASF INDIA LTD, DAHEJ as Executive production in PEOL and PESOL (Polyurethane) plant from 15 March-2013 to 29 May-2015. Worked in ATUL Ltd, Valsad. From 16 April-2011 to 13 March-2013. Designation: Senior Executive (production) at Polymers Division. Worked in Casil Industries Ltd. (Group of Cadila Pharmaceuticals Ltd) Kadi, Dist-Mehsana,Gujarat, as a Production Engineer From 1 Aug-2008 to 4 April- 2011. WORK PROFILE OF Lubrizol Advanced Materials India Pvt Ltd. Project Management Doing project commissioning and erection work. Evaluating project cost/ benefits analysis at project decision points. Participating in project review meetings for evaluating project progress providing technical inputs. Preparing P & ID of expansion work. Production Plant Operations Coordinating plant activities for the set up standards with accountability for strategic utilization & deployment of available resources to achieve organizational objectives. Record all HSE data of plant as an operation team safety representative. Assisting in preparing SOPs, manuals & work instructions for operations for the unit and maintaining reports for facilitating decision making by the management. Controlling and executing plant activities from SCADA (Siemens) Coordinating with another Department hassle free manufacturing. Preparations of audits. Trainings for new recruitments in operations. Doing SAP entries of process from raw material consumption to finished good packing.

- 3. Experience in extruder operation Quality Control/ Assurance Ensuring adherence to quality standards and maintaining all related documents. Identifying areas of quality failures and taking steps to rectify the system. Practicing quality standards with key emphasis on improving quality. WORK PROFILE OF BASF INDIA LTD. Man power handling, supervising and guiding operator and coordinating day to day activities. Looked after plant shut down and starts up activities and troubleshooting activities. Experience of handling Propylene Oxide, TDA, DEG, MEG etc. Worked with BASF technology team for successful production batch of Peol plant. Worked with TOYO Project persons for commissioning of PEOL (polyether Polyol) and PESOL (polyester Polyol) plants as a production site. Installation of SIS (safety instrument system) and SIL-3 (safety integrity level) for polyether Polyol plant. Prepared SOP, Pre-commissioning check list, work instruction, Recipe sequence steps involving in mfg. process and required document for Pre startup safety review of both Polyol plant. Attaining FAT & SAT (Site acceptance test) of DCS with SIEMENS at BASF site, Dahej. In FAT & SAT check the function test, interlock, recipe sequence and complex loops and DCS graphics. Maintaining close coordination with BASF project department and monitoring piping erection as per P & ID and equipment erection according to plot plant. Attaining PEOL process plant training at Ulsan, South Korea for 25 days and PESOL plant training at Thane, Mumbai for 30 days. WORK PROFILE OF ATUL LTD., VALSAD Handling batch process of Epoxy resin.

- 4. Handling all the process and operation with DCS of YOKOGAWA (centem-3000). Handling continues distillation in FFE and ATFE. Brine distillation with STEAM STRIPPING for recovering of ECH (SOLVENT). Process & operation : Dechlorination, Epoxidation, Stripping, Filtration, Drying WORK PROFILE OF CASIL INDUSTRIES LTD. (SPECIALITY CHEMICAL DIVISION) We are one of the leading Specialty chemical, Sulfolane manufacturer at Mehsana. ISO 9001 -2008 Certified Company. Sulfolane is manufacturing from Butadiene and Sulfur dioxide, by using Iso propyle Alcohol. We are making Sulfolene. Then by using Hydrogen they are making Sulfolane. Total production of Sulfolane is 60 TPM which is using in Petrochemical Industry’s for Extraction like extraction of Benzene, Toluene & Xylene from catalytic Reformat, Production of food grade Hexane for extraction of Edible Oils, Production of gasoline, Jet Fuels & special Boiling Point Solvents. PROCESS HANDLING: Batch process. Sulphonation: 20 kg/cm2 pressure system. Hydrogenation: 20 kg/cm2 pressure system. Epoxydation Distillation TECHNOLOGY ON HANDLING (DCS): Moore India ltd of APACS system. YOKOGAWA (centem-3000). Now work with SIEMENS. RAW MATERIAL HANDLING: Isopropyl alcohol, Butadiene, sulfur dioxide, hydrogen, Propylene oxide, Epichloro hydrin, Caustic, Toluene. JOB RESPONSIBILITY: Maintain document as per ISO Production planning, Scheduling, Monitoring and Controlling. Achieve Production and quality as per Target. Make shift wise production report, permit system, and maintain good housekeeping. Safe handling of material and minimize losses. Man power handling. Trouble shooting I do here declare that all the information that is furnished here are true the best of my knowledge